Scraper Filter

Self Cleaning Filter

Self Cleaning Filter Design

China Self Cleaning Filter

Brush Self Cleaning Filter

Manual Brush Filter

Self-cleaning Oil Filter

Self-cleaning Screen Filter

Self-cleaning Paint Filter

Self-cleaning Water Filter

Self-cleaning Basket Strainer

Self-cleaning Filter Irrigation

Self-cleaning Filter Wastewater

Self-cleaning Sediment Water Filter

Automatic Self Cleaning Filter

Automatic Self Cleaning Screen Filter

Automatic Brush Filter FL Series

Automatic Brush Filter FY Series

Automatic Brush Filter FW Series

Automatic Brush Filter FS Series

Automatic Brush Filter FZ Series

Automatic Sucking Filter X-FW Series

Automatic Sucking Filter X-FL Series

Hydraulic Filter AF-200 Series

Hydraulic Filter AF-800 Series

Automatic Backwash Filter

Automatic Backwashing Filter

Automatic Backwash Filters

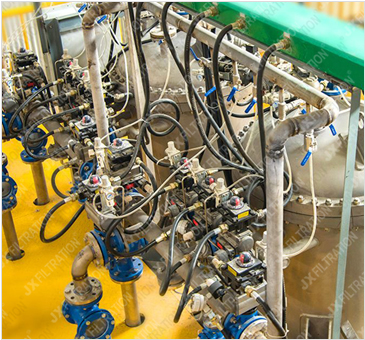

Automatic Backwash Filter System

Automatic Backwash Strainer

Automatic Back-flushing Filter

Automatic Back Wash Filters

Auto Backwash Filter Marine

Auto Backwash Filter Manufacturer

China Automatic Backwash Filter

Auto Backwash Filter

Auto Backwash Water Filter

Auto Backwash Filter Working Principle

Self Cleaning Filter Design

The filter with a compact and simple structure covers a small area.

High filtration precision: the filtering precision can reach 20 microns.

Continuous filtration with high filtering effect.

Automatic cleaning and discharge with low labor cost.

Suitable for most industries' filtration requirements.

Self Cleaning Filter Design

Description

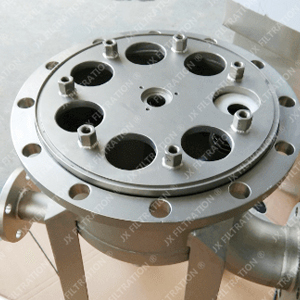

Self-cleaning filter is designed to meet the requirements of various liquid continuous filtration. It is composed of actuator, electric controller, drive motor, filter body, coarse filter element, control pipeline, fine filter element, inlet and outlet connection flange and other main parts.

The flow capacity, chemical properties of the filtering medium, suspended solids (SS) content of the filter medium, required filtration precision, and pipeline water pressure could influence the model selection of the self-cleaning filter.

Best Factory, Best Product. Contact Now !!!

Working Principle

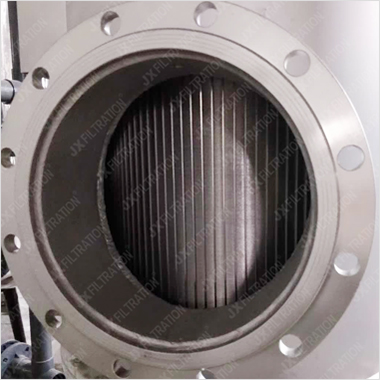

Filtering stage: The liquid flows through the screen from inside to outside, and impurities are blocked on the inner surface. After working for a while, the impurities gradually increase the pressure difference rises. Filter screen is cleaned according to the set pressure difference or regularly.

Cleaning stage: The motor drives the scraper or brush to clean the filter screen in a horizontal rotation motion. When the scraper or brush rotates, the impurities are cleaned by the brush and flow to the bottom of the filter. The filter will work continuously during cleaning.

Drain stage: After several times cleaning, the drain valve will regularly open to discharge the waste liquid with high concentration of impurities. The waste liquid can be recycled if need.

- Various cleaning control method: Pressure difference/time/manual/PLC.

- Reasonable internal structure design to ensure stable performance.

- Siemens English control systems are optional for simple operation and maintenance.

- World-famous brand's components with high reliability and low operating cost.

- The discharged waste liquid has a high impurity concentration and can be recycled.

| Flow Rate | Up to 4000m3/h |

| Filter Rating | SS304/316/316L |

| Cartridge |

Perforated screen (800-4000um) Woven wire screen (20-800um) Wedge wire screen (50-1000um) |

| Working Pressure | 0.18-1.6 Mpa (solenoid diaphragm valve) |

| Working Tem. | ≤95 ℃ |

| Turbidity | ≤60mg/L |

| Power Supply | 380V/50Hz or as required by the customer |

| Voltage | AC24V or as required by the customer |

| Cleaning Mode | Brush, scraper, etc. |

| Cleaning Time | 10-200s, adjustable |

| Control Mode | Pressure difference/time/manual/PLC |

- Water Treatment

- Petrochemical

- Metallurgy

- Electric Power

- Chemical

- Paint & Printing Ink

- Paper

- Food & Beverage

- Pharmaceutical

- Metal Processing Industries, etc.

Self Cleaning Filter Design

Related Product

Self Cleaning Filter Design

Our Service

Professional Pre-sale

Service

Filtration method and

equipment recommendation

Free CAD or 3D

drawing provided

Free phone call

Complete Service

During Sales

On time delivery

Equipment inspection

by photo or video

Secure and standard

package provided

After Sales Service

Installation assist by

phone call or video

Free accessories provide

for maintenance

Engineer sent for

solving onsite problem

Self Cleaning Filter Design

FAQ

Where is your factory?

We have three factories in Sichuan, Hebei, Jiangsu. Because the difference of customer locations, raw material price, factory wages and other considerations. In this way, we can provide the best quality product with lower cost.

Do you have a certification?

Yes. we have ISO/CE/BV/SGS/TUV certificate and patent certificate.

How about the delivery time?

Usually 1-15 days after prepayment is confirmed.

Do you have a design team?

Yes, we have. Providing drawing, electric drawing and others.

What is your payment?

T/T, L/C, Western Union, Paypal.

Can you provide certificate of origin?

yes, we can provide CO as well as FORM E, FOEM F and etc.

Can you accept OEM?

Yes, we could do OEM for you.

Can you send me a sample?

Yes.1-3 days for delivery.