Scraper Filter

Self Cleaning Filter

Self Cleaning Filter Design

China Self Cleaning Filter

Brush Self Cleaning Filter

Manual Brush Filter

Self-cleaning Oil Filter

Self-cleaning Screen Filter

Self-cleaning Paint Filter

Self-cleaning Water Filter

Self-cleaning Basket Strainer

Self-cleaning Filter Irrigation

Self-cleaning Filter Wastewater

Self-cleaning Sediment Water Filter

Automatic Self Cleaning Filter

Automatic Self Cleaning Screen Filter

Automatic Brush Filter FL Series

Automatic Brush Filter FY Series

Automatic Brush Filter FW Series

Automatic Brush Filter FS Series

Automatic Brush Filter FZ Series

Automatic Sucking Filter X-FW Series

Automatic Sucking Filter X-FL Series

Hydraulic Filter AF-200 Series

Hydraulic Filter AF-800 Series

Automatic Backwash Filter

Automatic Backwashing Filter

Automatic Backwash Filters

Automatic Backwash Filter System

Automatic Backwash Strainer

Automatic Back-flushing Filter

Automatic Back Wash Filters

Auto Backwash Filter Marine

Auto Backwash Filter Manufacturer

China Automatic Backwash Filter

Auto Backwash Filter

Auto Backwash Water Filter

Auto Backwash Filter Working Principle

Scraper Filter

Best choice for treating viscous liquid.

Fully automatic operation and continuous filtration.

High standard sealing to prevent leakage of hazardous materials.

Discharged liquid has high impurity concentration and can be recycled.

Simple structure: the scraper and screen mesh are easy to disassemble and clean.

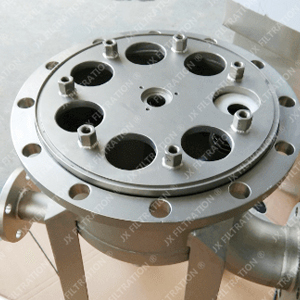

Scraper Filter

Description

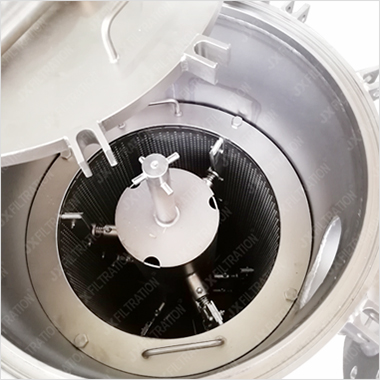

Scraper type self-cleaning filter is the ideal choice of filtering liquid with high viscosity, high corrosion, and high pressure.

It is widely applied in filtering solvents, acid-alkali, polymer, coating adhesive materials, etc. It has higher efficiency and precision of range 30-1500 microns. It can filter liquid viscosity up to 800000 centipoises.

The scraper type self-cleaning filter operates fully automatically. The high filtration precision, stable, and reliable performance makes it an efficient choice to replace a traditional manual filter or dumping type material filter. It can replace the conventional cartridge filters, bag filters, basket filters, and vibrating screen filters in many areas.

Note: Inner-scraper: scraper is inside the filtering element; outer-scraper: scraper is outside the filtering part.

Best Factory, Best Product. Contact Now !!!

Working PrincipleScraper self-cleaning filter's operation principle is very simple: Install the filter screen ② in a stainless steel cylindrical shell①. When unfiltered liquid flows into the shell from the inlet ③, solid impurities were leached and deposited on the screen's inner surface. Filtered fluid flows out from the outlet ④. When the filter screen needs cleaning (depending on the time, pressure differential, or manually choose), a clean dish tightened with spring scrapes the mesh inside the surface back and forth continuously and removes solid material deposition. When the debris is separated from the filter screen gap, the wash dish will send the dirt into the bottom of shell ⑥ and be discharged through the flow channel⑦.

| Housing | Carbon steel, SS304/316/316L |

| Filter Element | SS304/316/316L |

| Driveshaft Seal |

PTFE Teflon (suitable for all kinds of solvent, acid, or alkali liquid, the highest temperature: 230℃) NBR acrylic rubber (applicable to most of the neutral and oil liquid, the highest temperature: 120℃ ) VITON fluorine rubber (resistant to acid and alkaline liquid and the majority of solvent, the highest temperature: 230℃) |

| Sealing Ring | EPDM |

| Scraper |

SF (super water-resistant composite material) SS (wear-resistant stainless steel) |

| Tripod | SS304 |

| Model | Pipe Diameter (mm) |

Flow Rate (m3/h) |

Flow Area (m2) |

Drain Valve (mm) |

Filtration Rating (mm) |

Motor Power (KW) |

| JXS2-273 | 80 | 50 | 0.25 | 25 | 0.01-5 | 0.55 |

| JXS2-325 | 100 | 150 | 0.35 | 25 | 0.01-5 | 0.55 |

| JXS2-426 | 200 | 300 | 0.66 | 50 | 0.01-5 | 0.55 |

| JXS2-530 | 250 | 500 | 1.0 | 50 | 0.01-5 | 0.55 |

| JXS2-630 | 300 | 700 | 1.2 | 80 | 0.01-5 | 0.75 |

| JXS2-720 | 350 | 1100 | 1.5 | 80 | 0.01-5 | 0.75 |

| JXS2-820 | 400 | 1500 | 1.8 | 80 | 0.01-5 | 0.75 |

| JXS2-920 | 450 | 1700 | 2 | 80 | 0.01-5 | 0.75 |

- Water Treatment

- Petrochemical

- Metallurgy

- Electric Power

- Chemical

- Paint & Printing Ink

- Paper

- Food & Beverage

- Pharmaceutical

- Metal Processing Industries, etc.

Scraper Filter

Related Product

Scraper Filter

Our Service

Professional Pre-sale

Service

Filtration method and

equipment recommendation

Free CAD or 3D

drawing provided

Free phone call

Complete Service

During Sales

On time delivery

Equipment inspection

by photo or video

Secure and standard

package provided

After Sales Service

Installation assist by

phone call or video

Free accessories provide

for maintenance

Engineer sent for

solving onsite problem

Scraper Filter

FAQ

Where is your factory?

We have three factories in Sichuan, Hebei, Jiangsu. Because the difference of customer locations, raw material price, factory wages and other considerations. In this way, we can provide the best quality product with lower cost.

Do you have a certification?

Yes. we have ISO/CE/BV/SGS/TUV certificate and patent certificate.

How about the delivery time?

Usually 1-15 days after prepayment is confirmed.

Do you have a design team?

Yes, we have. Providing drawing, electric drawing and others.

What is your payment?

T/T, L/C, Western Union, Paypal.

Can you provide certificate of origin?

yes, we can provide CO as well as FORM E, FOEM F and etc.

Can you accept OEM?

Yes, we could do OEM for you.

Can you send me a sample?

Yes.1-3 days for delivery.