Scraper Filter

Self Cleaning Filter

Self Cleaning Filter Design

China Self Cleaning Filter

Brush Self Cleaning Filter

Manual Brush Filter

Self-cleaning Oil Filter

Self-cleaning Screen Filter

Self-cleaning Paint Filter

Self-cleaning Water Filter

Self-cleaning Basket Strainer

Self-cleaning Filter Irrigation

Self-cleaning Filter Wastewater

Self-cleaning Sediment Water Filter

Automatic Self Cleaning Filter

Automatic Self Cleaning Screen Filter

Automatic Brush Filter FL Series

Automatic Brush Filter FY Series

Automatic Brush Filter FW Series

Automatic Brush Filter FS Series

Automatic Brush Filter FZ Series

Automatic Sucking Filter X-FW Series

Automatic Sucking Filter X-FL Series

Hydraulic Filter AF-200 Series

Hydraulic Filter AF-800 Series

Automatic Backwash Filter

Automatic Backwashing Filter

Automatic Backwash Filters

Automatic Backwash Filter System

Automatic Backwash Strainer

Automatic Back-flushing Filter

Automatic Back Wash Filters

Auto Backwash Filter Marine

Auto Backwash Filter Manufacturer

China Automatic Backwash Filter

Auto Backwash Filter

Auto Backwash Water Filter

Auto Backwash Filter Working Principle

Automatic Brush Filter FL Series

Compact structure covering a small area.

Less pressure and cleaning water loss.

Widely applied in water treatment and chemical industry.

No need to change the filter element for over 10 years.

Simple Siemens control system in English version.

Automatic Brush Filter FL Series

Description

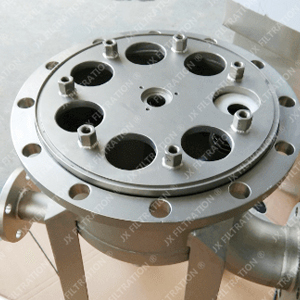

JX Brush Filter FL Series is a fully automatic self-cleaning electric device, which can reduce maintenance costs and protect downstream equipment. It uses a high-precision and high-intensity wedge wire filter element with an accuracy of 40-4000um.

There is continuous flow during backwashing, and the water consumption is very small, not exceeding 1% of the total flow. It is suitable for seriously polluted liquid with large flow rate.

Best Factory, Best Product. Contact Now !!!

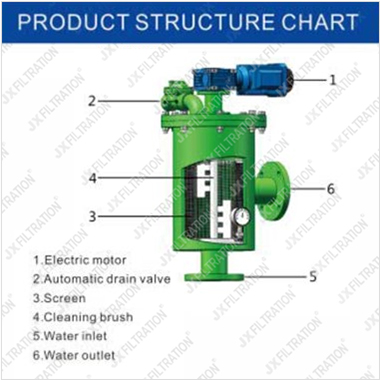

Working PrincipleThe water flows through the screen, and the particles are retained on the screen of the filter element. The filtered water flows out through the outlet. When the particles accumulated to a certain number and the pressure differential increases to the pre-determined level, the flushing cycle starts. It includes two steps: first, the automatic drain valve opens on the drainage outlet. The electronic motor then drives the cleaning brushes inside the screen, and the solids are expelled through the drain valve. Filters continue to supply filtered water when backwashing. The whole working system is controlled by a controller with several control modes: pressure differential, time, manual, and PLC.

- Short cleaning time: about 2-15 seconds without any intervention.

- The effective filtration area of the standard filter element is 7-40 times the entrance area.

- Various control methods: such as manual, pressure difference, time and PLC.

- Fully enclosed design and automatic operation mean virtually no operator intervention of materials contact.

- The connection method with the user pipeline is flange connection. The flange adopts the international standard flange with high versatility.

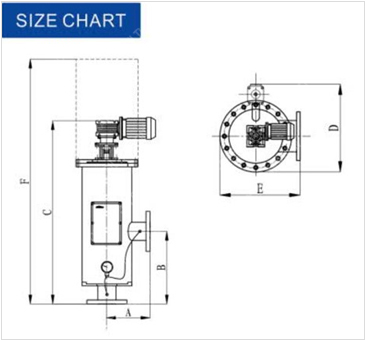

| Model | Connection | A (mm) |

B (mm) |

C (mm) |

D (mm) |

E (mm) |

F (mm) |

Drain outlet (mm) |

Motor (KW) |

Flow (m3/h) |

Weight (kg) |

| JXFL-50 | 50 | 240 | 250 | 700 | 560 | 420 | 900 | 25 | 0.12 | 19 | 50 |

| JXFL-65 | 65 | 240 | 250 | 700 | 560 | 420 | 900 | 25 | 0.12 | 30 | 70 |

| JXFL-80 | 80 | 240 | 250 | 700 | 590 | 420 | 900 | 40 | 0.12 | 50 | 80 |

| JXFL-100 | 100 | 240 | 400 | 950 | 590 | 420 | 1250 | 40 | 0.18 | 80 | 105 |

| JXFL-150 | 150 | 260 | 490 | 1080 | 610 | 420 | 1400 | 50 | 0.18 | 150 | 180 |

| JXFL-200 | 200 | 330 | 590 | 1410 | 680 | 518 | 1860 | 50 | 0.25 | 320 | 235 |

| JXFL-250 | 250 | 380 | 630 | 1490 | 780 | 620 | 1990 | 50 | 0.25 | 490 | 260 |

| JXFL-300 | 300 | 415 | 790 | 1850 | 830 | 680 | 2650 | 50 | 0.37 | 710 | 420 |

| JXFL-350 | 350 | 415 | 790 | 1850 | 830 | 680 | 2650 | 50 | 0.37 | 970 | 620 |

| JXFL-400 | 400 | 465 | 790 | 1950 | 930 | 780 | 2750 | 50 | 0.37 | 1260 | 738 |

| JXFL-450 | 450 | 510 | 790 | 1980 | 950 | 870 | 2860 | 50 | 0.37 | 1600 | 860 |

| JXFL-500 | 500 | 510 | 790 | 2100 | 1050 | 870 | 3050 | 65 | 0.55 | 1970 | 910 |

- Water Treatment

- Petrochemical

- Metallurgy

- Electric Power

- Chemical

- Paint & Printing Ink

- Paper

- Food & Beverage

- Pharmaceutical

- Metal Processing Industries, etc.

Automatic Brush Filter FL Series

Related Product

Automatic Brush Filter FL Series

Our Service

Professional Pre-sale

Service

Filtration method and

equipment recommendation

Free CAD or 3D

drawing provided

Free phone call

Complete Service

During Sales

On time delivery

Equipment inspection

by photo or video

Secure and standard

package provided

After Sales Service

Installation assist by

phone call or video

Free accessories provide

for maintenance

Engineer sent for

solving onsite problem

Automatic Brush Filter FL Series

FAQ

Where is your factory?

We have three factories in Sichuan, Hebei, Jiangsu. Because the difference of customer locations, raw material price, factory wages and other considerations. In this way, we can provide the best quality product with lower cost.

Do you have a certification?

Yes. we have ISO/CE/BV/SGS/TUV certificate and patent certificate.

How about the delivery time?

Usually 1-15 days after prepayment is confirmed.

Do you have a design team?

Yes, we have. Providing drawing, electric drawing and others.

What is your payment?

T/T, L/C, Western Union, Paypal.

Can you provide certificate of origin?

yes, we can provide CO as well as FORM E, FOEM F and etc.

Can you accept OEM?

Yes, we could do OEM for you.

Can you send me a sample?

Yes.1-3 days for delivery.