Scraper Filter

Self Cleaning Filter

Self Cleaning Filter Design

China Self Cleaning Filter

Brush Self Cleaning Filter

Manual Brush Filter

Self-cleaning Oil Filter

Self-cleaning Screen Filter

Self-cleaning Paint Filter

Self-cleaning Water Filter

Self-cleaning Basket Strainer

Self-cleaning Filter Irrigation

Self-cleaning Filter Wastewater

Self-cleaning Sediment Water Filter

Automatic Self Cleaning Filter

Automatic Self Cleaning Screen Filter

Automatic Brush Filter FL Series

Automatic Brush Filter FY Series

Automatic Brush Filter FW Series

Automatic Brush Filter FS Series

Automatic Brush Filter FZ Series

Automatic Sucking Filter X-FW Series

Automatic Sucking Filter X-FL Series

Hydraulic Filter AF-200 Series

Hydraulic Filter AF-800 Series

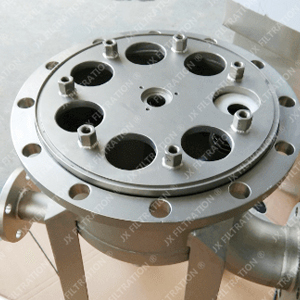

Automatic Backwash Filter

Automatic Backwashing Filter

Automatic Backwash Filters

Automatic Backwash Filter System

Automatic Backwash Strainer

Automatic Back-flushing Filter

Automatic Back Wash Filters

Auto Backwash Filter Marine

Auto Backwash Filter Manufacturer

China Automatic Backwash Filter

Auto Backwash Filter

Auto Backwash Water Filter

Auto Backwash Filter Working Principle

Auto Backwash Filter Working Principle

Extends the service life of filter elements.

Less consumables and maintenance cost.

Pneumatic and electric blowdown valve are optional.

Greater effectiveness and reduction in pressure drops.

Eradicates dissolved solids from water up to 25-3000 microns.

Auto Backwash Filter Working Principle

Description

JX Auto Backwash Filter could clean itself instantly after differential pressure has been reached. It has the advantages of saving costs and not requiring an external medium to clean filter elements in water treatment plants.

Automatic backwash filter system utilizes control panels to activate and monitor the backwashing process, which leads to zero human interruptions during the operation. The cleaning system can be controlled by preset pressure difference and time or manual.

Best Factory, Best Product. Contact Now !!!

Working Principle

Auto Backwash Filter Working Principle:Water enters from the inlet, passes through the coarse filter screen to filter out larger particles of impurities, and then reaches the fine filter screen.

The fine filter screen gradually accumulates dirt and impurities in the water to form a filter impurity layer during the filtration process. Because the impurity layer is accumulated on the inside of the fine filter screen, a pressure difference is formed between the inner and outer sides of the fine filter screen.

When the pressure difference of the filter reaches the preset value, the automatic cleaning process will start. During this time, the clean water supply is continuously flowing, the cleaning valve is opened, and the water pressure in the cleaning chamber and the sewage suction device drops significantly, passing through the filter cartridge and the sewage suction pipe.

Due to the pressure difference, a suction force is generated between the suction pipe and the cleaning chamber through the suction nozzle, forming a dirt suction process. Simultaneously, the electric motor drives the suction pipe to make a spiral movement in the axial direction.

The combination of axial movement and rotary movement of the dirt sucker completely cleans the entire inner surface of the filter.

The entire flushing process only takes tens of seconds. The drain valve is closed at the end of the cleaning. The filter is ready for the next flush cycle.

- Various installation methods are available.

- Energy-saving: low pressure and cleaning water consumption.

- The high tensile wedge wire filter element with long service life.

- During the backwashing process, each group of filter elements are backwashed in turn.

- The backwash pressure difference and time setting can be flexibly adjusted according to different water sources and filtration precision.

- Water and wastewater

- Pulp and paper

- Chemicals

- Petrochemical

- Iron and steel

- Nonferrous metal

- Plastic extrusion

- Machine coolant filtration

- Engineering, etc.

Auto Backwash Filter Working Principle

Related Product

Auto Backwash Filter Working Principle

Our Service

Professional Pre-sale

Service

Filtration method and

equipment recommendation

Free CAD or 3D

drawing provided

Free phone call

Complete Service

During Sales

On time delivery

Equipment inspection

by photo or video

Secure and standard

package provided

After Sales Service

Installation assist by

phone call or video

Free accessories provide

for maintenance

Engineer sent for

solving onsite problem

Auto Backwash Filter Working Principle

FAQ

Where is your factory?

We have three factories in Sichuan, Hebei, Jiangsu. Because the difference of customer locations, raw material price, factory wages and other considerations. In this way, we can provide the best quality product with lower cost.

Do you have a certification?

Yes. we have ISO/CE/BV/SGS/TUV certificate and patent certificate.

How about the delivery time?

Usually 1-15 days after prepayment is confirmed.

Do you have a design team?

Yes, we have. Providing drawing, electric drawing and others.

What is your payment?

T/T, L/C, Western Union, Paypal.

Can you provide certificate of origin?

yes, we can provide CO as well as FORM E, FOEM F and etc.

Can you accept OEM?

Yes, we could do OEM for you.

Can you send me a sample?

Yes.1-3 days for delivery.