Volute Press

Screw Press

Sludge Press

Dewatering Press

Screw filter Press

Volute Dewatering

Dewatering Screw

Dewatering Machine

Screw Press Dewatering

Dewatering Equipment

Volute Dewatering Press

Sludge Dewatering Press

Sludge Machine

Sludge Screw Press

Volute Screw Press

Sludge Press Machine

Industrial Screw Press

Wastewater Screw Press

Sludge Dewatering Press 131

Sludge Dewatering Press 251

Sludge Dewatering Press 301

Sludge Dewatering Press 351

Sludge Dewatering Press 401

Sludge Dewatering Press 404

Sludge Press Machine

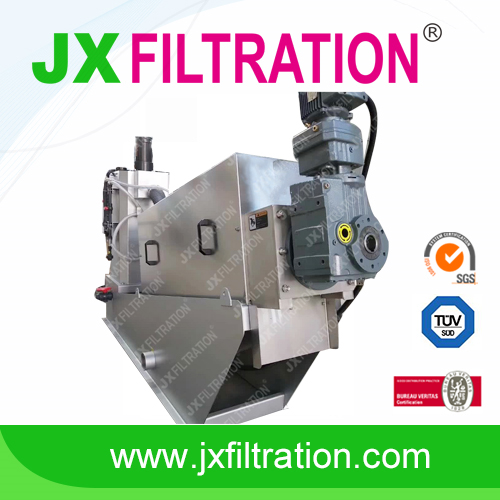

Description

JX Sludge Press Machine will concentrate the sludge by gravity in the thickening section, and sludge is transported to the dewatering section. As the filter gap and the pitch gradually become smaller and under the blocking effect of the backpressure plate, great internal pressure is generated, and the volume is continuously reduced to achieve sufficient dehydration.

The whole Sludge Press Machine is almost entirely made of stainless steel extending the service life. The only vulnerable parts are screw shafts and floating rings. It adopts automatic filter cake filtering technology to replace traditional filter sieve screen filtration.

Best Factory, Best Product. Contact Now !!!

Working Principle

The Sludge Screw Press is composed of main body, driving device, filtrate tank, mixing system, frame body, etc.

When it is working, the sludge is lifted to the mixing tank by the sludge pump. At this time, the dosing pump also quantitatively transports the liquid to the mixing tank, and the stirring motor drives the entire mixing system to combine the sludge with the liquid. This way could fully flocculate the material. When the liquid reaches the upper level of the liquid level sensor, it will send a signal to make the sludge screw press work. Under the action of the screw shaft, the sludge is lifted to the sludge outlet gradually, and the filtrate flows out from the gap between the fixed ring and the moving ring. The inner cavity formed by the screw shaft and the ring sheet is filled with flocculated particles, which are conveyed and squeezed to create a mud cake during the rotation of the end back pressure plate. The screw shaft rotates and pushes and continuously drives the movement of the moving ring up and down, left and right to clean the filter slits to prevent clogging.

- Reduce cleaning water and energy consumption.

- Working in a low speed and full enclosed condition to create a better production environment.

- Reduce the labor intensity of the operators and the daily maintenance time.

- The unique dynamic and static ring filter structure makes the machine not easy to block.

- Small net weight makes it is easy to transport to any production site.

- Municipal wastewater

- Food

- Beverages

- Slaughtering and breeding

- Printing

- Petrochemical engineering

- Paper making

- Tannery

- Pharmaceutical,etc.

Sludge Press Machine

Related Product

Sludge Press Machine

Our Service

Professional Pre-sale

Service

Filtration method and

equipment recommendation

Free CAD or 3D

drawing provided

Free phone call

Complete Service

During Sales

On time delivery

Equipment inspection

by photo or video

Secure and standard

package provided

After Sales Service

Installation assist by

phone call or video

Free accessories provide

for maintenance

Engineer sent for

solving onsite problem

Sludge Press Machine

FAQ

Where is your factory?

We have three factories in Sichuan, Hebei, Jiangsu. Because the difference of customer locations, raw material price, factory wages and other considerations. In this way, we can provide the best quality product with lower cost.

Do you have a certification?

Yes. we have ISO/CE/BV/SGS/TUV certificate and patent certificate.

How about the delivery time?

Usually 1-15 days after prepayment is confirmed.

Do you have a design team?

Yes, we have. Providing drawing, electric drawing and others.

What is your payment?

T/T, L/C, Western Union, Paypal.

Can you provide certificate of origin?

yes, we can provide CO as well as FORM E, FOEM F and etc.

Can you accept OEM?

Yes, we could do OEM for you.

Can you send me a sample?

Yes.1-3 days for delivery.