Volute Press

Screw Press

Sludge Press

Dewatering Press

Screw filter Press

Volute Dewatering

Dewatering Screw

Dewatering Machine

Screw Press Dewatering

Dewatering Equipment

Volute Dewatering Press

Sludge Dewatering Press

Sludge Machine

Sludge Screw Press

Volute Screw Press

Sludge Press Machine

Industrial Screw Press

Wastewater Screw Press

Sludge Dewatering Press 131

Sludge Dewatering Press 251

Sludge Dewatering Press 301

Sludge Dewatering Press 351

Sludge Dewatering Press 401

Sludge Dewatering Press 404

Sludge Machine

Description

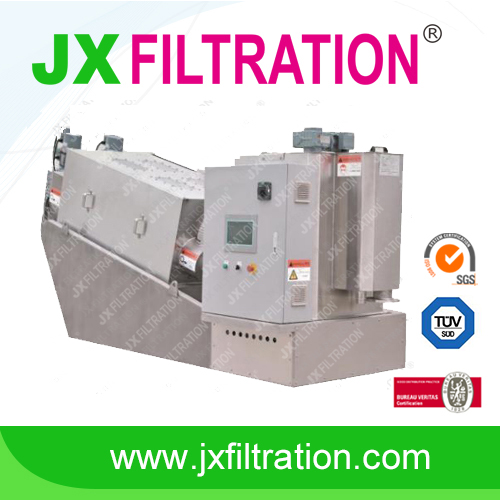

The design of the Sludge Dewatering Press: small size but complete equipment functions: the dehydrator contains an electric control cabinet, a metering tank, a flocculation mixing tank and a dehydrator main body. Due to its small size, it occupies a small space and is easy to repair and replace.

JX Sludge Machine has solved the major sewage treatment problems. It is now used in many industries: petrochemical, chemical fiber, papermaking, pharmaceuticals, leather and other industrial water treatment systems.

Best Factory, Best Product. Contact Now !!!

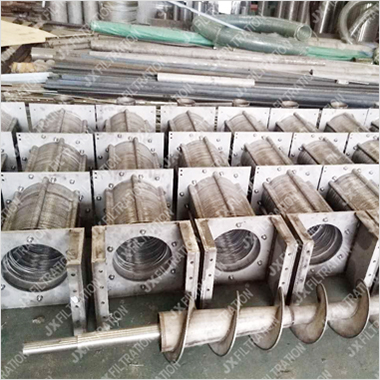

Working PrincipleThrough the strong extrusion force generated by the change of screw diameter and pitch and the tiny gap between the moving ring and the fixed ring, to realize the extrusion and dewatering of the sludge. The main body of the sludge dewatering press is composed of multiple fixed rings and moving rings, and the screw shaft penetrates through the filtering device. The front section is the thickening section, and the rear section is the dewatering section. The sludge thickening and dewatering are completed in one cylinder, replacing the traditional filter cloth and centrifugal filtration methods.

- The sludge is dewatering under the aerobic standard, and it is not easy to release the sludge phosphorus.

- Rotation speed of the screw shaft is about 2-3 r/min with low noise.

- The self-cleaning function is available with no clogging problems.

- Suitable for various types of sludge with high and low viscosity (2000mg/L-50000mg/L), especially oily sludge.

- The body is almost entirely made of stainless steel, and the only replacement parts are the screw shaft and dynamic disc.

- Municipal wastewater

- Food

- Beverages

- Slaughtering and breeding

- Printing

- Petrochemical engineering

- Paper making

- Tannery

- Pharmaceutical,etc.

Sludge Machine

Related Product

Sludge Machine

Our Service

Professional Pre-sale

Service

Filtration method and

equipment recommendation

Free CAD or 3D

drawing provided

Free phone call

Complete Service

During Sales

On time delivery

Equipment inspection

by photo or video

Secure and standard

package provided

After Sales Service

Installation assist by

phone call or video

Free accessories provide

for maintenance

Engineer sent for

solving onsite problem

Sludge Machine

FAQ

Where is your factory?

We have three factories in Sichuan, Hebei, Jiangsu. Because the difference of customer locations, raw material price, factory wages and other considerations. In this way, we can provide the best quality product with lower cost.

Do you have a certification?

Yes. we have ISO/CE/BV/SGS/TUV certificate and patent certificate.

How about the delivery time?

Usually 1-15 days after prepayment is confirmed.

Do you have a design team?

Yes, we have. Providing drawing, electric drawing and others.

What is your payment?

T/T, L/C, Western Union, Paypal.

Can you provide certificate of origin?

yes, we can provide CO as well as FORM E, FOEM F and etc.

Can you accept OEM?

Yes, we could do OEM for you.

Can you send me a sample?

Yes.1-3 days for delivery.