South Africa+High Frequency Dewatering Screen+Tailings

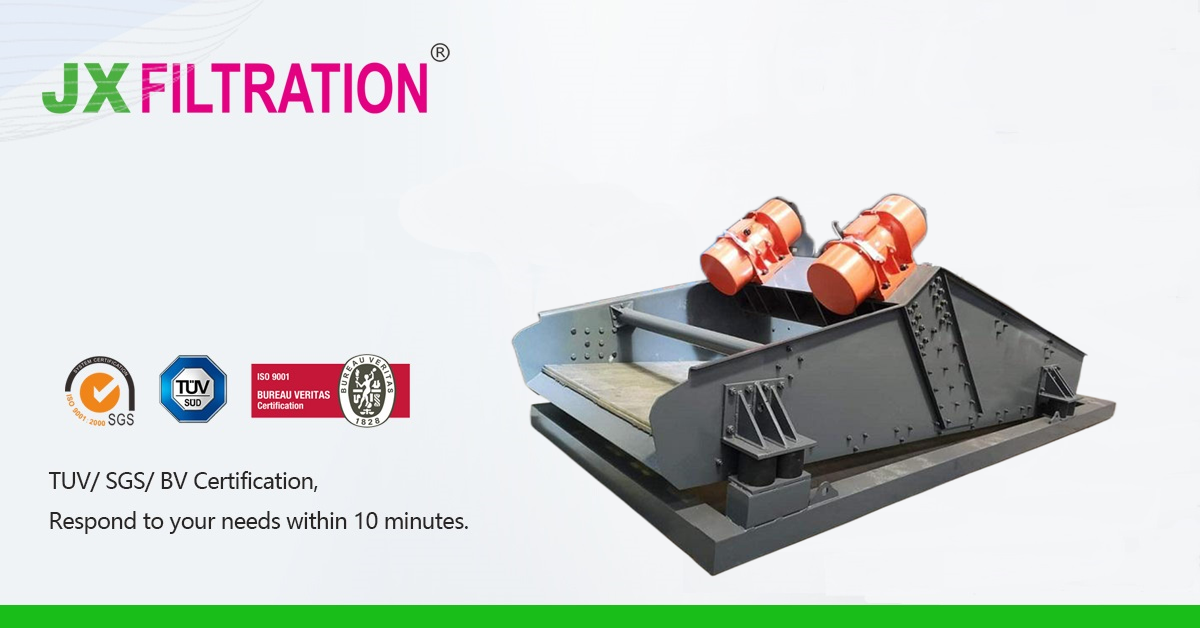

Product: High Frequency Dewatering Screen

Country: South Africa

Application: Tailings

Dewatering screen relies on polyurethane screen to realize the dehydration, screening and desliming of materials. It can generally be used for the production line of sand and gravel plants, the production of cement or the recovery of coal slime in coal preparation plants, and it can also be used for some tailings dry discharge treatment. Therefore, it can also be called tailings dry discharge dewatering screen or coal slime dewatering screen, etc. However, the dewatering screen structure for treating different materials is also different. Here, we mainly introduce sand and gravel vibrating dewatering screen. After dehydration, the materials can be used as sand and gravel aggregates with high cleanliness and low water content.

- Type: Dewatering screen

- Material: polyurethane screen

- Application: Tailings

- Capacity: 180 tons per hour

- Filtration accuracy: 3 mm

Working Principle:

The structure of the vibration dewatering screen is composed of eccentric block, vibrator, screen box, vibration exciter, supporting system and motor, etc. The overall structure design is relatively simple and compact, so the floor space is not large.

The dewatering screen drives the belt coupling by double vibration motors and drives the vibrator to run synchronously and reversely. The centrifugal force generated by two eccentric blocks is superimposed along the component of its vibration direction to offset the reverse centrifugal force. Thus, a single exciting force along the vibration direction is formed, which urges the screen box to make reciprocating linear motion. The materials on the screen are constantly jumping from the feed inlet to the discharge outlet through the vibration of the screen box, and the screening of the materials is completed in this process. The materials smaller than the screen holes will fall through the screen, and the remaining materials will be discharged from the discharge outlet.

Advantages:

1.The screen of dewatering screen equipment is often impacted, corroded and ground by materials, so it is a wearing part. Therefore, the material selection of the vibrating screen is very important. The screen of the vibrating dewatering screen is made of polyurethane screen with high wear resistance, corrosion resistance and low temperature resistance, which is not easy to wear, and the screen can be lubricated by itself, which can ensure its working stability.

2. Dewatering screen adopts the base design of rubber spring, which has a good damping effect in production and is not easy to be damaged. In addition, it can also ensure the stability of its amplitude and achieve better dehydration effect.

3. The mesh screen of dewatering screen can be changed, and it is also very convenient to operate. Customer can choose the appropriate mesh size according to the material size.

Application:

It can be used for sand washing in sand and gravel plant, coal slime recovery in coal preparation plant, dry discharge of tailings in concentrator, soil repair, slurry treatment, sewage treatment, etc

After-Sale Services

- Quality guarantee: 12 months after the equipment having been operated.

- Satisfied after-sell service: free maintenance and inspection.

- Detailed installation instructions, CAD drawing and product qualification certificate.

Any Requirements, Contact Us Now!

Nina

Email/Teams:nina@filtrationchina.com

Mobile/Whatsapp/Wechat: +86 17269571060