Spain + Sludge Dewatering Press + Wastewater Treatment

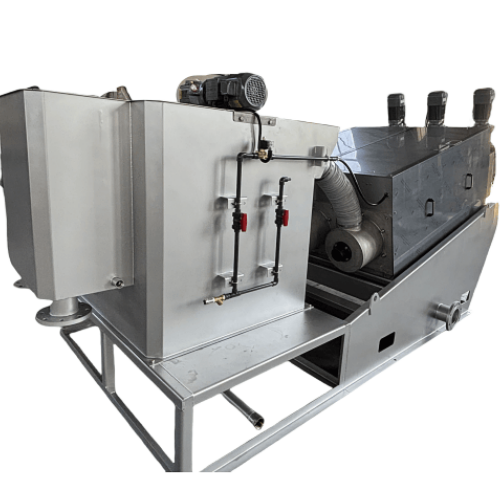

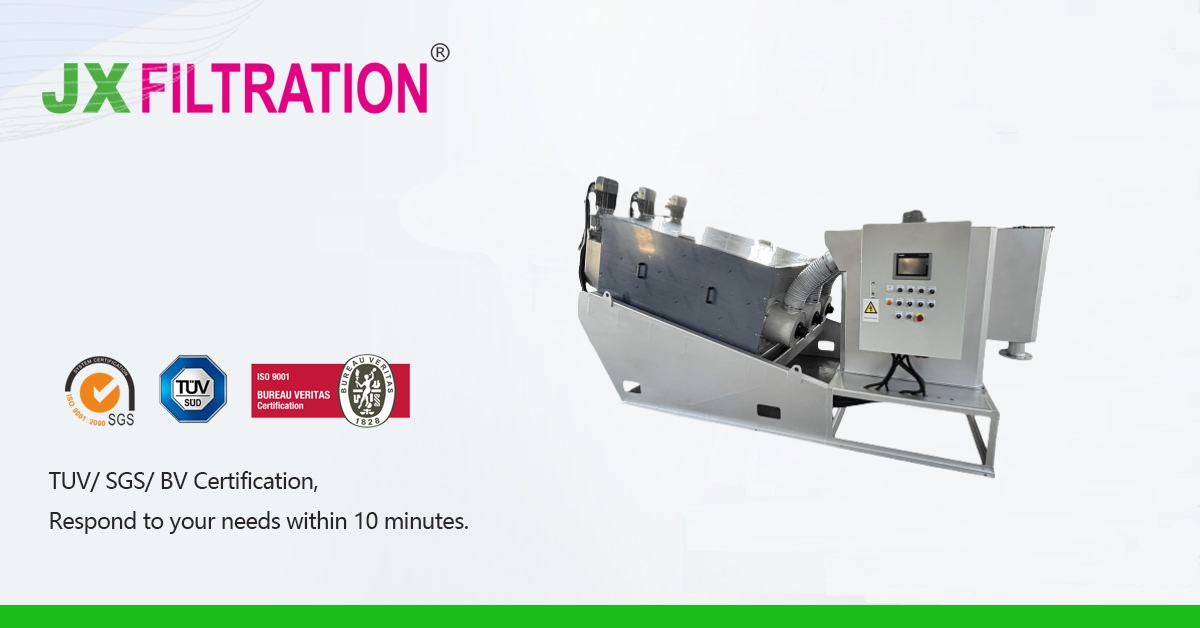

Product: Sludge Dewatering Press

Country: Spain

Application: Wastewater Treatment

In the wastewater treatment industry, the reliability of equipment during long-term operation and the control of maintenance costs are crucial for the continuous operation of any facility.

Recently, we collaborated with a wastewater treatment plant in Spain, which has been operating stably for ten years, providing them with a customized 353-Sludge Dewatering Press for their equipment upgrade project. This high-efficiency, low-cost solution helps the client address new sludge treatment challenges.

Customer Requirements: Precision, Professionalism, and Control.

This wastewater treatment plant has accumulated extensive experience through years of operation, but it also faces new challenges due to aging equipment and changes in sludge characteristics. The client's specific requirements were:

- Replace the existing centrifuge with a screw press sludge dewatering system, specifying the 353 model made of 304 stainless steel.

- Use Siemens and Schneider brand components for the core electrical system.

- Ensure high performance and low maintenance costs for wear parts.

Our Solution: Professional Customization + High Reliability Design.

Based on the client's specific needs, we leveraged our ten years of experience in R&D and manufacturing of water treatment equipment to provide the following tailored services:

1. Precise Equipment Selection and Parameter Confirmation.

The client specified the 353-Sludge Dewatering Press with a DS Sludge treating capacity of 300-360 kg/h. We provided detailed equipment parameters and technical drawings for the client's review and confirmation.

2. Strict Adherence to Specified Components.

We configured the electrical system exactly according to the client's specified brands and models.

3. Optimized Design for Maintenance Needs.

The client was particularly concerned about the wear resistance and maintenance cycle of the rotating ring. We reinforced the material and structure of the rotating ring in the 353 model, ensuring easy replacement of the shaft and rotating ring components.

4. Free Drawings and Customized Services.

We provided complete equipment drawings and technical recommendations, and our professional team assisted the client with equipment integration and process optimization.

Why Choose Us?

- Ten Years of Industry Experience: We have extensive experience in wastewater treatment equipment manufacturing, enabling us to quickly understand customer needs and provide mature solutions.

- Flexible Customization: From model, material to electrical components, we fully support customer-specified configurations.

- Professional Technical Support: We provide free parameter catalogs, equipment drawings, and process recommendations, reducing the customer's decision-making costs.

- Reliability Guarantee: Key components are made of high-quality brands, ensuring long service life and easy maintenance.

After-Sale Services

- Quality guarantee: 12 months after the equipment having been operated.

- Satisfied after-sell service: free maintenance and inspection.

- Detailed installation instructions, CAD drawing and product qualification certificate.

Any Requirements, Contact Us Now!

Nina

Email/Teams: nina@filtrationchina.com

Mobile/WhatsApp/WeChat: +86 17269571060