Poland + Ultrasonic Vibrating Screen + PVC Materials

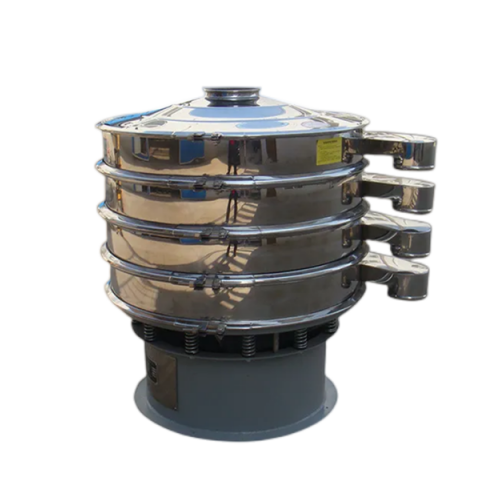

Product: Ultrasonic Vibrating Screen

Country: Poland

Application: PVC Materials

In the global chemical industry, fine screening of PVC materials has always been a critical step in the production process. PVC powders, especially fine powders, often face three major challenges during screening:

- Electrostatic adsorption: Static electricity easily builds up between particles, causing clumping and compromising screening accuracy and efficiency.

- Slight stickiness: The material easily adheres to the screen, causing blockage, requiring frequent downtime for cleaning, and significantly reducing production capacity.

- High precision requirements: The quality of the final product depends on the purity and consistency of the screened material. Any blockage can lead to excessive impurities.

Traditional vibrating screens often struggle to cope with these challenges. This is where our ultrasonic vibrating screens come into play. Given the characteristics of PVC materials, we recommend a customized ultrasonic vibrating screen system. This system cleverly combines a traditional vibrating motor with an ultrasonic screen cleaning device. High-frequency ultrasonic vibrations are transmitted to the screen surface, effectively breaking the material's surface tension, reducing electrostatic adsorption, and thus preventing clogging. Its core technological advantages include:

High-frequency ultrasound for thorough screen cleaning

The ultrasonic transducer integrated into the screen generates high-frequency, low-amplitude ultrasonic vibration waves, which are transmitted directly to the screen surface. This effectively breaks down the surface tension and electrostatic adsorption of PVC powder, freeing adhering particles, preventing clogging at the root and ensuring continuous screening.

Improved Precision and Efficiency

Under the action of ultrasound, the screen remains constantly activated, allowing PVC particles to pass more smoothly through the mesh. This not only significantly improves the efficiency and precision of a single screening pass (especially for fine screening of 80 to 600 mesh sizes), but also ensures product consistency between batches.

Intelligent Control for Energy Saving and Cost Reduction

The equipment is equipped with an advanced intelligent control system, allowing customers to flexibly adjust the ultrasonic power and vibration frequency based on the characteristics of each PVC batch for optimized production. Furthermore, the overall energy consumption of the equipment is lower than that of traditional high-vibration screens, complying with EU energy conservation and environmental protection standards.

Durable and Easy to Maintain

Targeted at the continuous production requirements of the chemical industry, we use high-quality materials and a sealed design, resulting in a durable equipment with significantly extended screen life, significantly reducing long-term operating and maintenance costs for customers.

If your company is also troubled by the screening problems of materials such as PVC, chemical fiber, metal powder, etc., please feel free to contact us. We are happy to provide you with free material screening tests and professional technical consultation, and present you with the most ideal solution with facts and results.

After-Sale Services

- Quality guarantee: 12 months after the equipment having been operated.

- Satisfied after-sell service: free maintenance and inspection.

- Detailed installation instructions, CAD drawing and product qualification certificate.

Any Requirements, Contact Us Now!

Nina

Email/Teams: nina@filtrationchina.com

Mobile/WhatsApp/WeChat: +86 17269571060