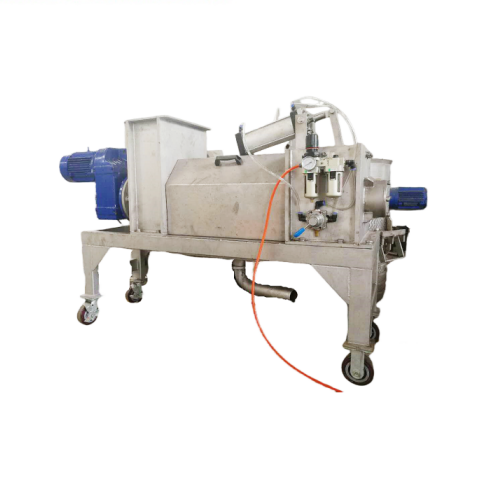

Argentina + Screw Press + Solid-Liquid Separation

Product: Screw Press

Country: Argentina

Application: Solid-Liquid Separation

Screw Press is a mechanical device that uses the principle of screw propulsion to squeeze and dehydrate materials. It is widely used in food processing, environmental protection, chemical industry, agriculture and other fields. Its core is to generate continuous extrusion force through the rotation of the screw shaft to separate the liquid in the material and achieve solid-liquid separation.

Main structure and working principle

- Screw shaft: core component, usually with variable pitch or variable diameter design, which pushes the material forward when rotating and gradually increases the pressure.

- Screen filter cartridge: porous structure wrapped around the screw shaft, allowing liquid to seep out while retaining solids.

- Drive device: provides power to control the speed of the screw shaft.

- Discharge port and liquid discharge port: discharge the dehydrated solid residue and separated liquid respectively.

Workflow

The material enters from the feed port, is pushed forward with the rotation of the screw shaft, is compressed in a gradually shrinking space or increased pitch, and the liquid is discharged through the screen and the solid is discharged from the end.

Classification of screw presses

- Single screw press: simple structure, suitable for general materials.

- Twin screw press: The twin shafts rotate in opposite directions, which makes the extrusion more thorough and suitable for high-fiber or sticky materials.

- Belt screw press: Combined with belt pressing, it is used in scenarios with low pressure requirements.

Screw presses have become key solid-liquid separation equipment in modern industry due to their high efficiency and flexibility, especially in the fields of resource recovery and environmental protection.

After-Sale Services

- Quality guarantee: 12 months after the equipment having been operated.

- Satisfied after-sell service: free maintenance and inspection.

- Detailed installation instructions, CAD drawing and product qualification certificate.

Any Requirements, Contact Us Now!

Nina

Email/Teams: nina@filtrationchina.com

Mobile/WhatsApp/WeChat: +86 17269571060