Various Oily Sludge Treatment Solutions

Treatment of crude oil and soil, oil sludge at the bottom of tank at oil and gas station, and oily sludge in sedimentation tanks.

Three kinds of oily sludge

- Crude oil and soil: In the process of drilling and test spraying in the oil extraction process, a large amount of crude oil falls on the ground and mixes with soil, sand, gravel, water and other substances to form a mixture of oil and soil. The oil content of it is generally 10%-30%. As there are all kinds of domestic garbage at the oil production site, in addition to mud and sand, there are also glass bottles, mineral water bottles, bags and other domestic garbage and other solid wastes in the sludge.

- Oil sludge at the bottom of tank at the gas station: When crude oil is stored for a long time in the storage tank of an oil and gas station, the high melting point wax, asphaltenes, colloids and the entrained silt and other inorganic impurities in the crude oil will become sediments together with the water, forming oily sludge at the bottom of the storage tank to reduce the effective volume of the storage tank.

- Oily sludge in sedimentation tanks: Waste oil from oil refineries, petrochemical plants and other industries is usually poured directly into large sedimentation tanks. The oily sludge produced by sedimentation is called oily sludge in sedimentation tanks.

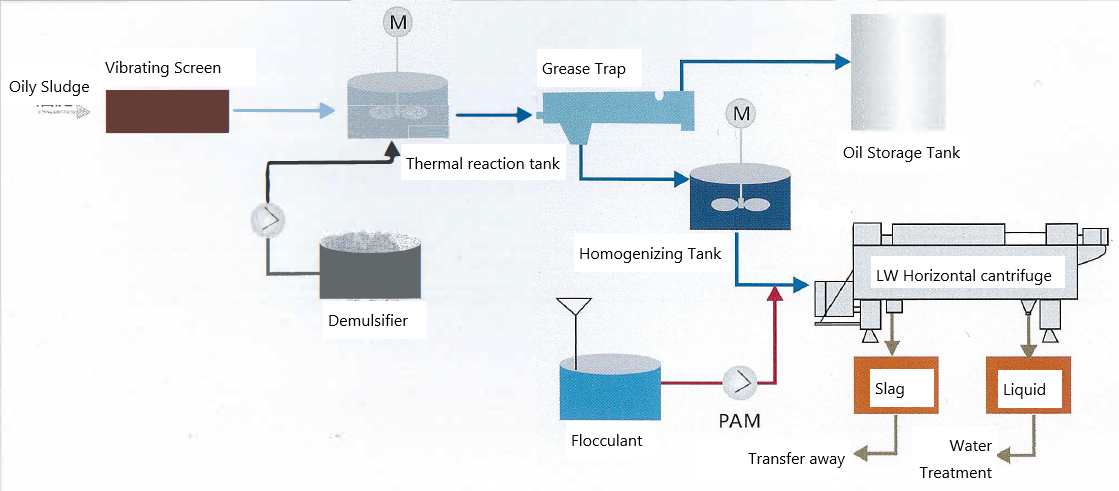

Solution 1: High-efficiency LW series two-phase centrifuge

Working principle

After collecting the oily (waste) water by steam heating, add appropriate demulsifiers, active agents, etc., so that the oily water in the emulsified state can be demulsified. Then the oily (waste) water is separated by natural sedimentation in the grease trap. The upper layer of oil floating on the grease trap is collected and then enters the oil storage tank for further processing. The water in the middle layer of the grease trap, the undemulsified oil-water mixture and the sludge settled on the bottom layer are collected to enter the mixing tank for further processing. Using the high-efficiency LW series two-phase centrifuge to carry out the continuous separation of (oil + water) + slag. The centrifuge separated water and the undemulsified oil-water mixture are directly sent to the sewage treatment system for treatment. The high-efficiency dehydration LW series two-phase centrifuge can be used to complete this dehydration task. The slag phase after dehydration can be burned or thermally desorbed to recover the residual crude oil.

Among them, the Crude oil and soil needs to be vibrating and screened before heating and demulsification to remove large particles of soil, sand, glass bottles, mineral water bottles, bags, gauze and other solid wastes. Vibrating screens are used after pulping and demulsification for further remove the large particles of sand and then enter the centrifuge for separation.

Technological Points

1. Demulsifiers and surfactants can improve the efficiency of demulsification, increase the subsequent separation efficiency, increase the oil recovery rate and reduce the oil content in the slag phase.

2. Heating can reduce the viscosity of the oil, increase the oil recovery rate and reduce the solid content of the oil and water.

3. Adding PAM flocculant can increase the solid recovery rate and reduce the solid content in the liquid phase.

4. The use of high-efficiency LW series two-phase centrifuge can improve separation efficiency, increase oil recovery, and reduce residual oil content.

5. Water treatment solid-liquid separation uses high-efficiency LW series two-phase centrifuges, which can reduce the liquid content of the slag phase, facilitate transportation and increase the heat value of combustion.

Performance

- It can recover about 70-85% of oil (related to oil density, demulsification effect, temperature, etc.), and the recovered oil can be used for oil refining through further purification by a disc centrifuge.

- The dryness of the slag phase after centrifuge separation can reach 40~60%, and the total volume is reduced by more than 80% compared with before separation.

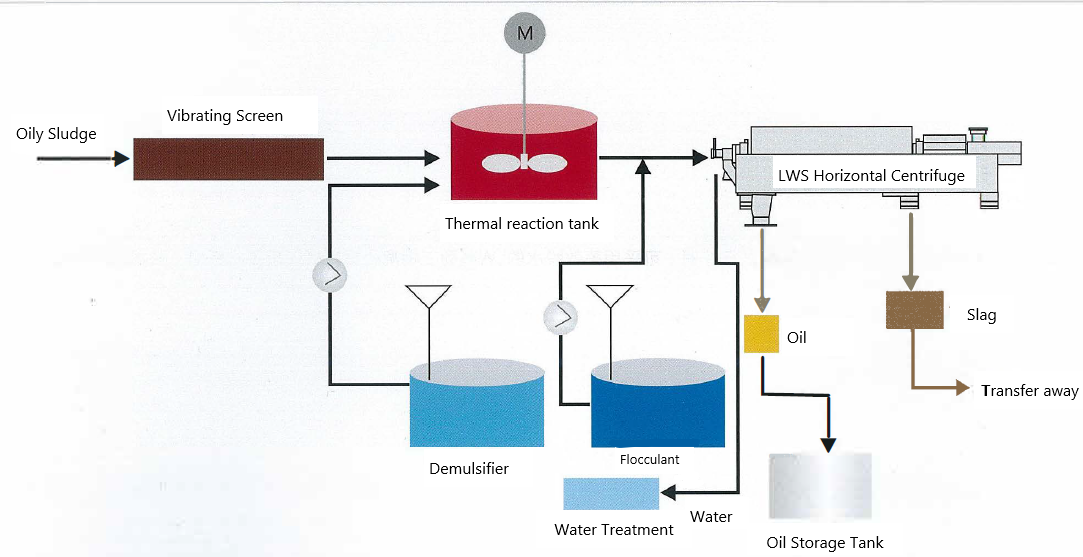

Solution 2: High-efficiency LWS series three-phase centrifuge

Working principle

The oily (waste) water is collected and heated by steam, and suitable demulsifiers, active agents, etc. are added to make the oily water in the emulsified state to achieve demulsification. The oily (waste) water after demulsification adopts high-efficiency LWS series three-phase centrifuge performs the continuous separation of oil + water + slag. The water separated by the centrifuge and the undemulsified oil-water mixture are directly sent to the sewage treatment system for treatment. It can be completed by the LW series two-phase centrifuge for dehydration. After dewatering, the slag phase can be burned or thermally desorbed to recover residual crude oil. The separated oil can be collected and used as crude oil.

Among them, the Crude oil and soil needs to be vibrating and screened before heating and demulsification to remove large particles of soil, sand, glass bottles, mineral water bottles, bags, gauze and other solid wastes. Vibrating screens are used after pulping and demulsification for further remove the large particles of sand and then enter the centrifuge for separation.

Performance

1. It can recover about 80~90% of oil (related to oil density, demulsification effect, temperature, etc.), and the recovered oil can be used for oil refining through the further purification of the disc centrifuge.

2. The water content of the oil phase after separation by the centrifuge can reach ≤3~5%.

3. The dryness of the slag phase after centrifuge separation can reach 40~60%, and the total volume is reduced by more than 80% compared with before separation.

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160