Three-phase Oily Sludge Pyrolyzation System

By adjusting the system parameters, the Three-phase Oily Sludge Separation System can handle a variety of oily wastes such as spin dryer drill cuttings, solid control drill cuttings, tank bottom oil sludge,etc. This system mainly uses natural gas or diesel as fuel to indirectly heat oil-containing pollutants, and uses high temperature to vaporize the organic matter such as water, crude oil or polycyclic aromatic hydrocarbons, and separate them from solids. Through the recovery system, resources such as crude oil, non-condensable gas, water or organic matter are recovered.

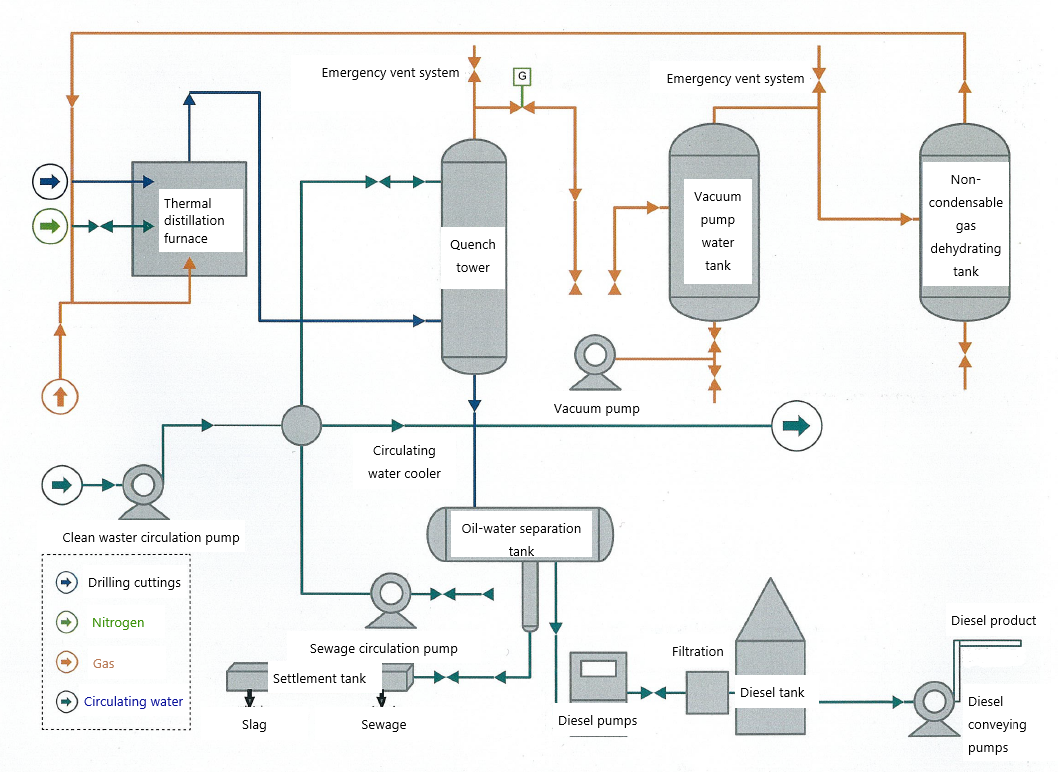

The system consists of feeding material pool, conveying unit, distribution unit, explosion-proof pyrolysis chamber, discharge unit, oil and gas recovery system, non-condensable gas recovery system, discharge end dust-proof cooling unit, central control room, etc.

Working Principle

The oily sludge is incinerated to a certain temperature under anaerobic conditions (generally around 450°C or even higher), then the hydrocarbons are separated in the complex hydration and cracking reactions. The hydrocarbons can be condensed and recovered. This technology has the advantages of completely inorganicizing oily sludge, efficient recovery and utilization of hydrocarbons, fast processing speed and thorough processing.

Performance

Through heating and distillation, the oil and gas resources in the material are discharged and recovered. The oil content of the residue after processing by the process equipment is less than 0.3%, comply with the ultra-clean emission environmental protection standards for general solid waste treatment in domestic and international oilfield.

Features

- The adiabatic pyrolysis system can operate continuously and efficiently, which improves the processing efficiency and production capacity.

- It meets European and American emission standards, and the exhaust gas of the production line has been tested. All emission indicators not only meet national standards, but also comply with EU EEA and US EPA standards.

- Proprietary hot air tightness technology to ensure safe and reliable operation.

- Proprietary non-coking, thermal dispersion technology, so that the material can be heated uniformly and pyrolyzed fully.

- Proprietary gas purification and waste heat recycling technology, the purified combustible gas is used as fuel for the heating system, and the waste heat is fully utilized. The heat energy required for the pyrolysis process is completely self-supplied to reduce the operating cost.

- Proprietary catalytic pyrolysis technology, low energy consumption, improves the output rate and quality of oil products.

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160