What is the Working Principle of an RO System?

The working principle of an RO (reverse osmosis) system is based on the selective permeability of a semi-permeable membrane. Its core lies in using high pressure to drive water molecules to permeate backward through the membrane layer, thereby achieving efficient separation of dissolved impurities in water. Here is a simplified explanation of the key steps:

1. Comparison of Natural Osmosis and Reverse Osmosis

- Natural Osmosis: When a low-concentration solution (such as pure water) and a high-concentration solution (such as brine) are separated by a semi-permeable membrane, water molecules will spontaneously flow from the low-concentration side to the high-concentration side until the concentrations on both sides reach equilibrium (e.g., water absorption by plant roots).

- Reverse Osmosis (RO): By applying an external pressure higher than the natural osmotic pressure (typically 10–70 bar), water molecules are forced to pass backward through the semi-permeable membrane from the high-concentration side (raw water) to the low-concentration side (product water), while dissolved salts, heavy metals, bacteria, and other impurities are retained on the membrane surface.

2. Key Filtration Mechanisms of RO Membranes

- Pore Size Accuracy: RO membranes have a pore size of approximately 0.0001 micrometers (5000 times smaller than bacteria), effectively intercepting:

- Dissolved solids (such as sodium, calcium, and chloride ions)

- Organic pollutants (pesticides, viruses)

- Colloids and microorganisms

- Separation Process: Raw water passes through the membrane under high pressure. Pure water (permeate) is collected, while the trapped pollutants are discharged with a portion of the concentrate, preventing membrane clogging.

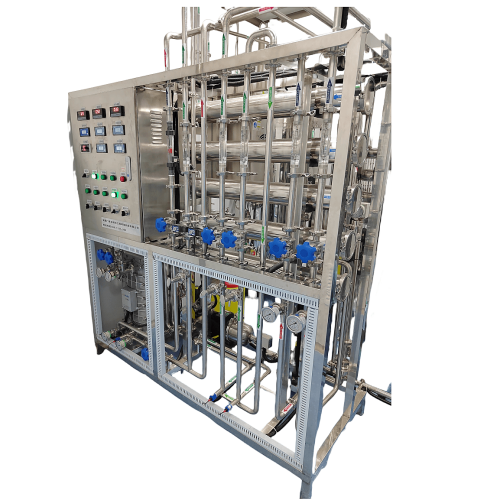

3. Typical RO System Workflow

- Pretreatment: Suspended solids and residual chlorine are removed through multi-stage filters (such as sand filters and carbon filters), protecting the RO membrane from oxidation or physical damage.

- High-Pressure Pump Pressurization: The pretreated water is pressurized to the required operating pressure for the membrane.

- Membrane Separation: Water molecules permeate through the membrane to become pure water, while pollutants are concentrated and discharged as concentrate.

- Post-Treatment (Optional): Mineralization, UV sterilization, and other units can be added as needed to adjust water quality.

4. Core Advantages

- High Desalination Rate: Removes 90–99% of dissolved impurities.

- No Chemical Additives Required: Environmentally friendly and safe physical separation process.

- Wide Applications: Covers seawater desalination, drinking water purification, and industrial ultrapure water production.

If you have specific application scenarios (such as industrial wastewater reuse or drinking water systems), JX Filtration can provide further equipment selection advice or technical parameter optimization solutions.

Any requirements, contact us now!

Nina

Email: nina@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 172 6957 1060