Solid Waste Treatment of Drilling Oil-based Slurry

Oil field drilling requires drilling oil-based slurry according to the drilling depth and geological conditions. Its basic composition is oil, water, organic clay and oil-soluble chemical treatment agent.

The oil-based slurry is resistant to high temperature and salt calcium corrosion is conducive to the stability of the well wall. It has good lubricity and less damage to the oil and gas reservoirs. It is widely used in various drilling platforms. But in the drilling solids control system equipment (vibrating screen, centrifuge, spin dryer), the slag has seriously affected environmental safety and must be treated in a harmless manner. After the treatment, the oil content of the slurry is below 1%, and the obtained oil can be further purified and reused.

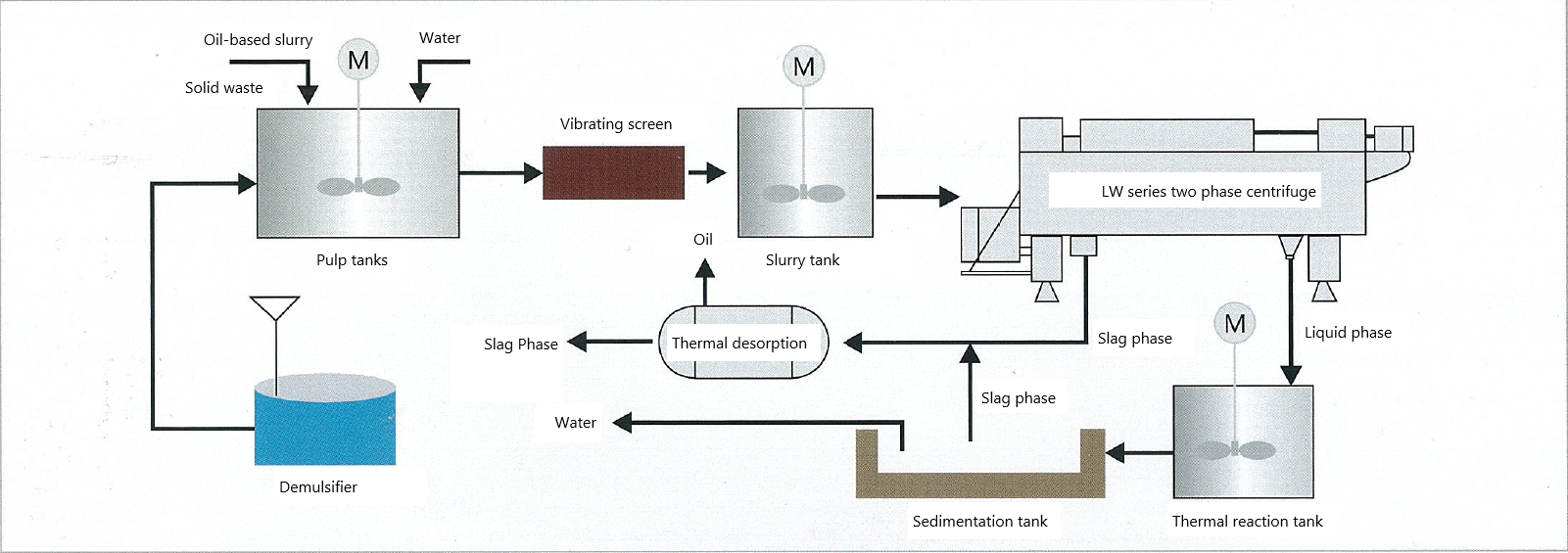

Working Principle

The collected drilling oil-based solid waste water is mixed at high speed in proportion to the slurry. Then appropriate demulsifiers, active agents, etc. are added to make the oil and water in the emulsified state to achieve demulsification. Before separation, a vibrating screen is required to remove the large particles of soil, sand, gravel, glass bottles, mineral water bottles, bags, gauze and other solid wastes. Then use the high-efficiency LW series two-phase centrifuge to carry out the two-phase (oil + water) + slag continuous separated. After the separated liquid phase is heated by steam, it enters the sedimentation tank, skims off the supernatant. Finally, mixing the slag phase after sedimentation at the bottom and centrifuge separation and adopting the thermal desorption process to recover the residual oil.

Performance

- It can recover about 90% of oil (related to demulsification effect, temperature, etc.)

- The solid content of the liquid phase after separation by the centrifuge can reach ≤5~8%.

- The dryness of the slag phase separated by the centrifuge can reach 40~60%.

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160