Oily Wastewater Treatment for Refinery

For the treatment of oily wastewater, the purpose is to recover more oil and reduce the oil content in solids.

At present, for the oily wastewater produced in processing crude oil in refineries, the treatment mode of rough flocculation + dehydration is widely used, but the slag phase after dehydration is directly used for incineration. This causes a waste of crude oil resources.

Now we can use high-efficiency LWS series three-phase centrifuges after a series of pretreatments (adding demulsifiers, surfactants, etc.) to reuse crude oil.

Working Principle

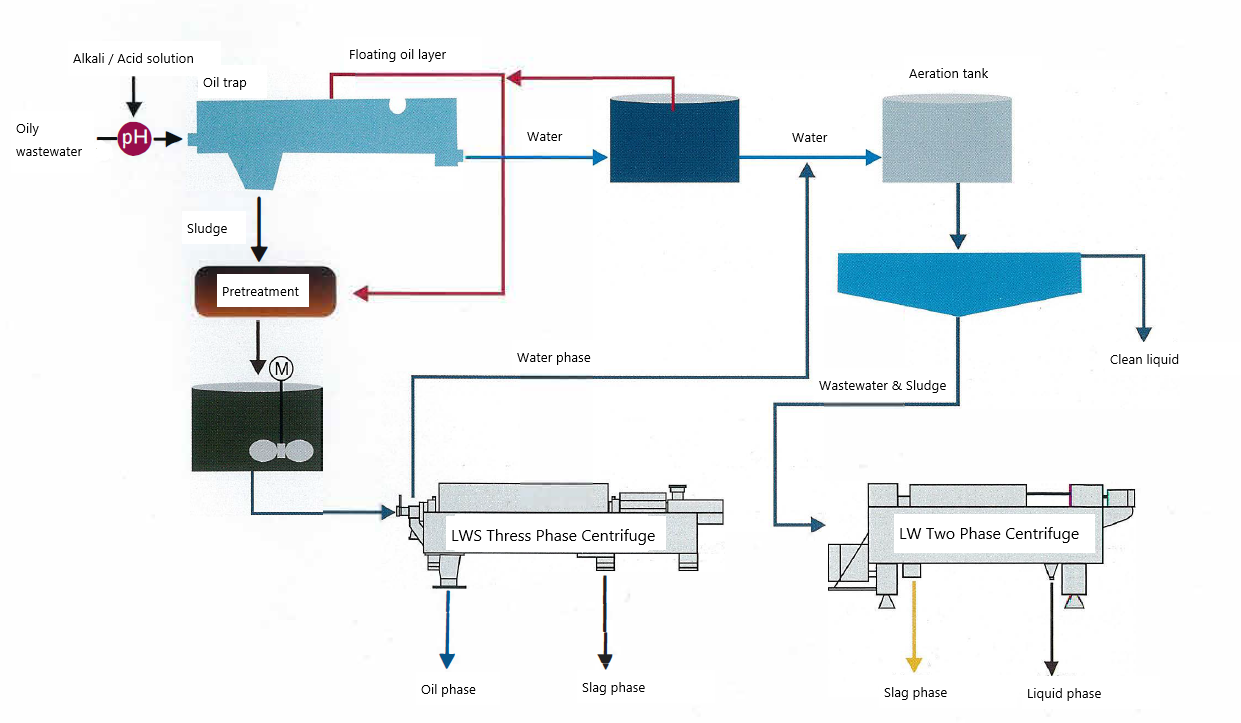

After collecting the oily wastewater, add appropriate demulsifiers, active agents, etc. to make the oily water in the emulsified state realize demulsification. Then the oily wastewater is separated by natural sedimentation in an oil trap. The water in the middle layer of the oil tank and the undemulsified oil-water mixture are directly transfer to the sewage treatment system. The efficient LW series two-phase centrifuge can be used to complete this dehydration task. The upper oil slick floating in the oil trap and the sludge settled in the bottom layer are collected and then transfer to the mixing tank for further treatment. The treated oil sludge can be continuously separated by the high-efficiency LWS series three-phase centrifuge for oil + water + slag.

Working Procedure

- Demulsifiers and surfactants can improve the efficiency of demulsification, increase the subsequent separation efficiency, increase the oil recovery rate and reduce the oil content in the residue phase.

- Heating can reduce the viscosity of the oil, increase the oil recovery rate and reduce the solid content of the oil and water.

- Adding PAM flocculant can increase the solid recovery rate and reduce the solid content in the liquid phase.

- The high-efficiency LWS series three-phase centrifuge is used for the separation of oil + water + slag, which can improve the separation efficiency, increase the oil recovery rate, and reduce the slad oil content.

- The use of high-efficiency LW series two-phase centrifuges for solid-liquid separation in water treatment can reduce the liquid content of the slag phase, facilitate transportation and lift off the combustion heat value.

Performance

- It can recover about 80-95% of oil (related to oil density, demulsification effect, temperature, etc.). The recovered oil can be further purified by a disc centrifuge and can can be used for oil refining.

- The oil separated by the centrifuge the oil phase moisture content can reach ≤3~5%.

- The dryness of the slag phase after centrifuge separation can reach 40~60%, and the total volume is reduced by more than 80% compared to before separation.

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160