Oily Sludge Treatment System in Petroleum Industry

Application:

Oil-bearing sludge produced in the process of oil extraction, pipeline transportation, oil and gas combined stations, oil refineries, oily wastewater, etc.

Working Principle

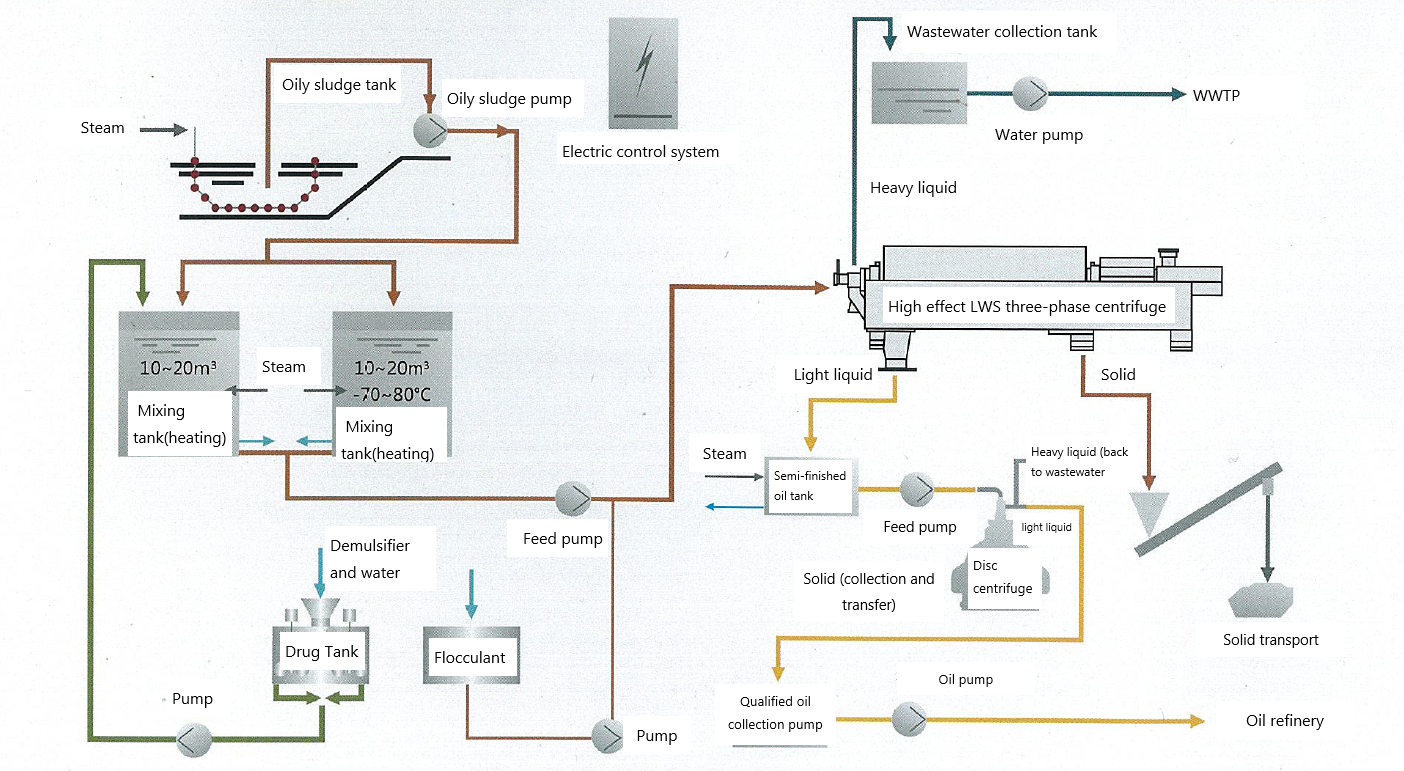

Oily sludge treatment is a complete production process, using the principles of oxidative demulsification and centrifugal separation. The main equipment is composed of a dosing system, a feeding system, a separation system, a conveying system, and a control system.

After the oily sludge is collected, it is heated by steam, and appropriate demulsifiers, active agents, etc. are added to make the oily water in the emulsified state achieve demulsification.

The oily (waste) water after demulsification is used the high-efficiency LWS series three-phase centrifuge performs three-phase continuous separation of oil + water + solid. The water separated by the centrifuge and the undemulsified oil-water mixture are directly sent to the sludge treatment system for treatment. High-efficiency LW series two-phase centrifuge completes the dehydration process. The solid phase after dehydration can be burned or thermally desorbed to recover the residual crude oil. The separated crude oil is collected and then purified by a three-phase disc centrifuge. The purified oil can be reused.

Performance

- It can recover about 80~90% of oil (related to oil density, demulsification effect, temperature, etc.), and the recovered oil can be used for oil refining through further purification.

- The moisture content of the oil phase after separation by the centrifuge can reach ≤3~5%.

- The dryness of the solid phase after centrifuge separation can reach 40~60%, and the total volume is reduced by more than 80% compared with before separation.

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160