Product

Disk Stack Centrifuge

Our Advantage

All parts contacting with fluid are made of stainless steel, conforming the food-level requirement.

The drum of our disc centrifuge is precisely tested with dynamic balance. Large spiral gears are used in transmission system to guarantees the stable operation, overload-proof, small vibration, safety running and convenient operation.

The bearings are from famous Swedish brand SKF, fully ensuring the operation precision.

With the PLC control, our disc centrifuge can also achieve program operation.

Disk Stack Centrifuge

Description

disk stack centrifuge is composed of inlet/outlet device, drum, vertical/horizontal shafts, housing, speed detector, brake, motor and etc. The material is discharged with centripetal pump after separation. With a high output pressure (0-0.5mpa), the material be directly delivered to the downstream equipment.

BEST FACTORY, BEST PRODUCT. CONTACT NOW !!!

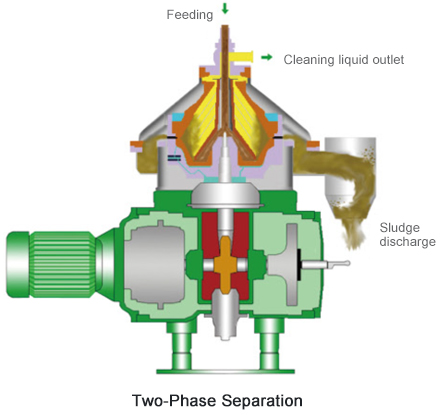

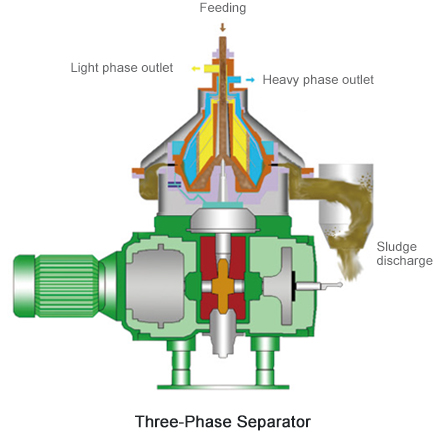

Working principle

When the raw liquid was fed into the high speed rotating drum, it enters the disc stack along the channel.

With the effect of strong centrifugal force, raw liquid with different densities forms three dynamic concentric

rings. Small amount of solid particles with biggest density keep moving outward and pile up on the drum

which formed the outmost layer. Heavy liquid with bigger density is throwed to the lower surface of the disc

and then slip out of the disc area to form the middle layer. Light liquid with smaller density keeps moving

toward the drum center and forms the innermost layer. Finally, the components of each layer will be

discharged from their channels respectively.

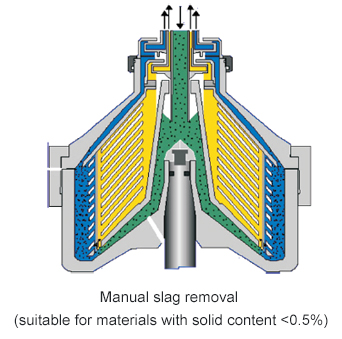

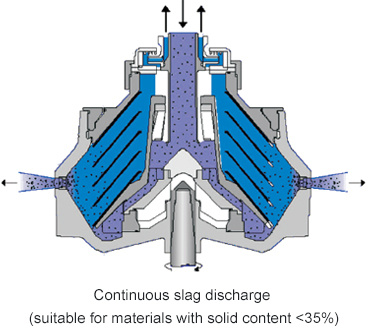

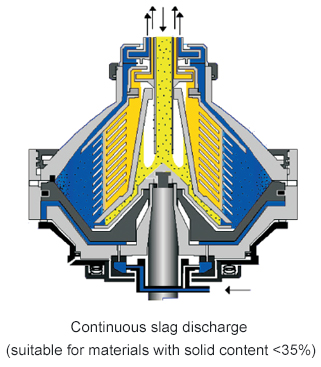

Slag discharge way

Applications

● Milk separator: for milk skimming or clarification (solid impurity removal). Small separator is driven with labor

aid and drain manually, which is suitable for domestic use of farmers and herdsmen. Large separators are

driven electrically and suitable for industrial production.

● Mineral oil separator: used for the removal of water and mechanical impurities from mineral oil, including the

fuel oil, diesel oil, lubricating oil and transformer oil. It is also able to separate similar emulsion.

● Plant oil separator: the processing and refinement of plant oil.

● Animal oil separator: used to refine animal oil in meat processing or to concentrate and separate fish oil in

aquatic processing.

● Yeast separator: used to concentrate the yeast.

● Starch separator: used for starch removal and starch concentration.

● Wool fat separator: used in wool industry to extract wool grease from wool washing water.

● Pharmaceutical disc separator: used in the pharmaceutical industry for the extraction of antibiotics, vitamins,

etc. It is also suitable for the 3-phase mixture separation in pharmaceutical and chemical production.

● Beer separator: used for the clarification of beer, wort and other beverages.

● Latex separator: used for the concentration of rubber milk and for the removal of impurities from rubber milk.

● Paint separator: used to separate the impurities in the paint, improving the quality of the paint.

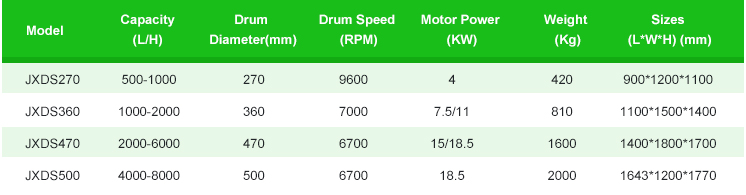

Model Selection

Disk Stack Centrifuge

Related Product

Product

Disk Stack Centrifuge

FAQ

Where is your factory?

We have three factories in Sichuan, Hebei, Jiangsu. Because the difference of customer locations, raw material price, factory wages and other considerations. In this way, we can provide the best quality product with lower cost.

Do you have a certification?

Yes. we have ISO/CE/BV/SGS/TUV certificate and patent certificate.

How about the delivery time?

Usually 1-15 days after prepayment is confirmed.

Do you have a design team?

Yes, we have. Providing drawing, electric drawing and others.

What is your payment?

T/T, L/C, Western Union, Paypal.

Can you provide certificate of origin?

yes, we can provide CO as well as FORM E, FOEM F and etc.

Can you accept OEM?

Yes, we could do OEM for you.

Can you send me a sample?

Yes.1-3 days for delivery.

Disk Stack Centrifuge

Our Service

Professional Pre-sale

Service

Filtration method and

equipment recommendation.

Free CAD or 3D

drawing provided.

Free phone call.

Complete Service

During Sales

On time delivery.

Equipment inspection

by photo or video.

Secure and standard

package provided.

After Sales Service

Installation assist by

phone call or video.

Free accessories provide

for maintenance.

Engineer sent for

solving onsite problem.