Dewatering Screw Press Working Principle

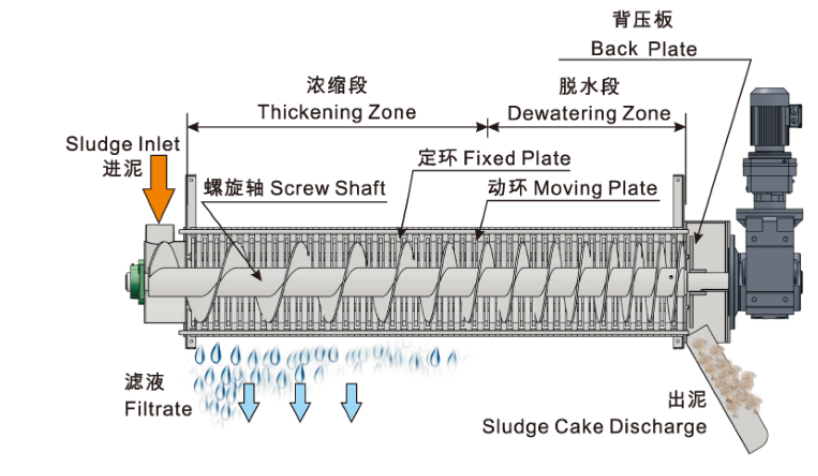

The Dewatering Screw Press uses the principle of screw extrusion. Through the strong extrusion force generated by the change of screw diameter and pitch, as well as the tiny gap between the moving ring and the fixed ring, the sludge is squeezed and dewatered.

The Dewatering Screw Press adopts a multi-overlap spiral filter press method, which has the features of self-cleaning filter slits, no block, saves water and electricity and durable. It creates a direct dewatering of low-concentration sludge (2000mg/L~), and can realize 24-hour continuous unmanned operation, while greatly reducing the cost of design, construction, operation and maintenance management.

When the Dewatering Screw Press is working, the sludge is lifted to the mixing tank by the sludge pump. At this time, the dosing pump also quantitatively transports the liquid to the mixing tank, and the stirring motor drives the entire mixing system to combine the sludge with the liquid. Perform sufficient mixing to produce alum. When the liquid level reaches the upper level of the liquid level sensor, the liquid level sensor will get a signal at this time, so that the motor of the main body of the screw press starts to press and filter the sludge. Under the action of the screw shaft, the sludge is lifted to the sludge outlet step by step, and the filtrate flows out from the gap between the fixed ring and the moving ring.

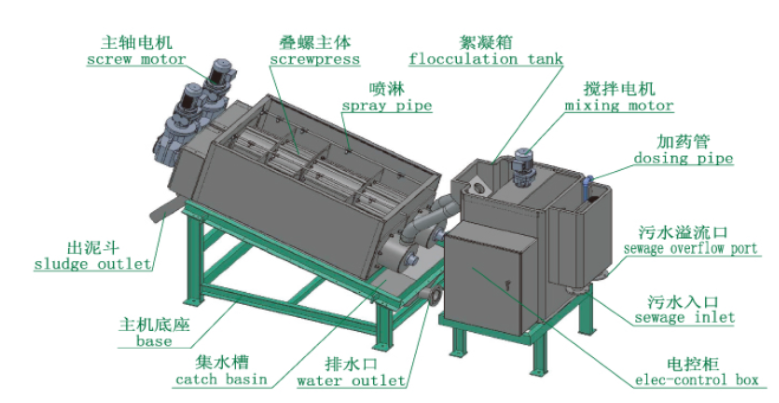

The Dewatering Screw Press is composed of screw press, driving device, filtrate tank, mixing system, frame and etc.

Screw Press

The screw press is composed of a fixed ring, a moving ring, a screw shaft, a screw, a gasket and a number of connecting plates. The whole screw press body is made of stainless steel 304. The fixed ring is connected together by six screws. A gasket and a moving ring are installed between the fixed ring and the moving ring. Both the fixed ring and the moving ring are made of wear-resistant materials, which makes the life of the whole machine longer. The screw shaft passes through the fixed ring and the moving ring.

The screw shaft is composed of a taper shaft and a spiral blade. The outer circle of the screw shaft blade directly contacts the moving ring to generate friction, and the surface of the blade is always in contact with the sludge.

Driving Device

The drive device is the power source of the equipment, and the performance of the drive device will directly affect the performance of the whole machine. The motor protection class is IP54 and the insulation class is F. Explosion-proof motors can also be used according to customer requirements, and frequency conversion starting and speed regulation methods can be used to suit different application conditions and avoid load impact.

Filtrate Tank

The filtrate tank is welded by stainless steel 304 plates to collect the filtrate filtered by the Dewatering Screw Press. The filtrate tank is connected with the frame body by screws, and flanges are provided on the side of the filtrate tank to facilitate connection with external equipment.

Mixing System

The mixing system is mainly used to fully mix the sludge and the medicament to form alum, which is then fed into the main body of the screw press for squeezing and dewatering. The mixing tank is provided with a sludge inlet, an overflow port and a vent port, and a liquid level adjustment device is provided, so that the sludge feed amount can be adjusted.

Frame

The frame body is welded by high-strength channel steel, and the surface is treated with anti-corrosion.

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160