Product

Dewatering Screw Press

Our Advantage

Large capacity, high efficiency and small occupying space.

Compact structure, easy operation and maintenance.

High TDS and saltwater tolerance Chemical treatment flexibility.

Dewatering Screw Press

Description

Dewatering Screw Press is mainly designed for the purpose of dewatering the organic sludge. It reaches the goal of extrusion dewatering sludge by the powerful extrusion pressure of changing the screw diameter and distance, and the tiny spacing between movable annular plates and fixed annular plates.

BEST FACTORY, BEST PRODUCT. CONTACT NOW !!!

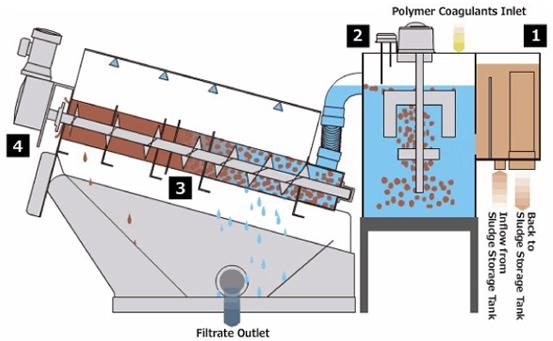

Working Process

Flow control tank:Sludge feed is regulated with the overflow pipe, returning excess volume to the sludge storage tank.

Flocculation tank: Polymer flocculant and sludge are stirred and mixed, forming floc suitable for the Dewatering Screw Press. Then, the built-in thickener in the tank instantly thicken the sludge.

Cylinder unit: Sludge is further thickened in the thickening zone of the cylinder, and then the inner pressure increased at the dewatering zone helps sludge being dewatered well.

Discharge outlet for dewatered cake:Further pressure is applied from the outlet side with the end plate, discharging dewatered case with 20+-5% solid content.

Application

-Municipal water and wastewater treatment plants.

-Agricultural/fishery community wastewater treatment plants

-Industrial waste treatment plants

-Food/beverage production plants

-Dairy farming/Meat processing plants

- Chemicals manufacturing plants

-Machinery manufacturing/Metal processing plants

-Laundry wastewater

-Other (paper manufacturing, building material manufacturing, oilfield associated water accompanied with crude oil mining, etc. )

Dewatering Screw Press

Related Product

Dewatering Screw Press

Related Cases

Product

Dewatering Screw Press

FAQ

Where is your factory?

We have three factories in Sichuan, Hebei, Jiangsu. Because the difference of customer locations, raw material price, factory wages and other considerations. In this way, we can provide the best quality product with lower cost.

Do you have a certification?

Yes. we have ISO/CE/BV/SGS/TUV certificate and patent certificate.

How about the delivery time?

Usually 1-15 days after prepayment is confirmed.

Do you have a design team?

Yes, we have. Providing drawing, electric drawing and others.

What is your payment?

T/T, L/C, Western Union, Paypal.

Can you provide certificate of origin?

yes, we can provide CO as well as FORM E, FOEM F and etc.

Can you accept OEM?

Yes, we could do OEM for you.

Can you send me a sample?

Yes.1-3 days for delivery.

Dewatering Screw Press

Our Service

Professional Pre-sale

Service

Filtration method and

equipment recommendation.

Free CAD or 3D

drawing provided.

Free phone call.

Complete Service

During Sales

On time delivery.

Equipment inspection

by photo or video.

Secure and standard

package provided.

After Sales Service

Installation assist by

phone call or video.

Free accessories provide

for maintenance.

Engineer sent for

solving onsite problem.