Bag Filter Housings

Single Bag Filter Housing

PP Bag Filter Housing

Duplex Bag Filter Housing

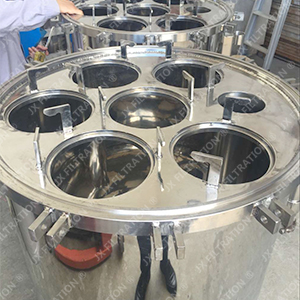

Multi-Bag Filter Housing

4-Bag Filter Housing

6-Bag Filter Housing

8-Bag Filter Housing

12-Bag Filter Housing

18-Bag Filter Housing

24-Bag Filter Housing

32-Bag Filter Housing

Quick Opening Bag Filter Housing

Jacketed Bag Filter Housing

Filter Vessel

Bag Filter Vessel

Bag Filter Vessels

Bag Filter Housing

SS Bag Filter Housing

Bag Filter Housing Stainless Steel

Stainless Steel Bag Filter Housing

Bag Filter Housing Manufacturer

Bag Filter Housing-Best Manufacturer

Filter Bag

Filter Bag

Description

The filter bag is mainly used in petrochemical, coatings and paints, biomedicine, automobile manufacturing, food and beverage, industrial dust removal and other fields. It is characterized by a loose fiber structure and a high rate of increase in impurities' capacity.

This fiber material is a compound interception mode, which effectively removes solids and soft particles. Larger impurities are trapped on the fiber's surface. In contrast, fine particles are captured in the filter material's deep layer to ensure that filter bag will not damage due to pressure increase.

Best Factory, Best Product. Contact Now !!!

| Size | Max flowrate(m3/h) | Filter area (m2) |

Volume (L) |

Dia. (mm) |

DLength. (mm) |

Processing mode | Material | |

| 1-3μm | 5-200μm | |||||||

| #01 | 8 | 16 | 0.25 | 8.0 | 180 | 440 | Steel wire seam /Plastic hot melting | PE/PP/MO |

| #02 | 20 | 32 | 0.50 | 17.0 | 180 | 810 | Steel wire seam /Plastic hot melting | PE/PP/MO |

| #03 | 3 | 6 | 0.09 | 1.3 | 102 | 210 | Steel wire seam | PE/PP/MO |

| #04 | 6 | 12 | 0.16 | 2.5 | 102 | 380 | Steel wire seam | PE/PP/MO |

| Material | Temperature* (℃) |

Water | Aliphatic series |

Aromatic series |

Weak base | Weak acid | Alkali | strong acid |

| PP | 90 | ● | ● | ● | ● | ● | ● | |

| PE | 160 | ● | ● | ● | ● | ● | ● | |

| Nylon | 160 | ● | ● | ● | ● | ● | ||

| * approximate value ●applicable | ||||||||

Remarks: the above information is reliable but does not mean that it is a guarantee.

The user needs to make a test to determine the appropriate filter material.

According to the actual requirements of the filtration process, to determine the filtration mode (deep filtration, surface filtration) first, and then choose the filter bag material by Table 2

According to the filter flow rate, medium viscosity, filter precision, to determine the size of the filter bag by Table 1

Filtration products of different materials have different filtration modes, filtration efficiency, and filtration precision. Besides, the filtration efficiency would vary with temperature, viscosity, flow velocity, and filtrate quality. Please select the most suitable filter material according to the actual working conditions.

| MOC | Filtration precision available (μm) | |||||||||||

| 1 | 5 | 10 | 15 | 25 | 50 | 75 | 100 | 125 | 150 | 200 | 300 | |

| PP | √ | √ | √ | √ | √ | √ | √ | √ | ||||

| PE | √ | √ | √ | √ | √ | √ | √ | √ | ||||

| MO | √ | √ | √ | √ | √ | √ | √ | |||||

Remarks: the above information is reliable but does not mean that it is a guarantee.

The user needs to make a test to determine the appropriate filter material.

| Mesh | 12000 | 5000 | 2500 | 1250 | 625 | 550 | 300 | 200 | 140 | 120 | 100 | 70 | 60 | 50 |

| μm | 1 | 3 | 5 | 10 | 20 | 25 | 50 | 70 | 100 | 125 | 149 | 200 | 250 | 300 |

There are many kinds of filter products with different materials. Different filtrates also have other physical and chemical characteristics. In the process of filtration, Filter material must be compatible with it, without chemical reaction. Furthermore, filter material must also face the same pressure and temperature change as filtrate to maintain its fixed structure. Stable and uniform filtration efficiency can be guaranteed only without aperture change, softening, crack, or effusion.

| MOC | Solvent | Strong acid | Weak acid | Strong base | Weak base | Surface affinity | Temp. tolerance (℃) |

| NC | 3 | 5 | 5 | 1 | 1 | Oleophilic, hydrophilic | 150 |

| PP | 4 | 1 | 1 | 1 | 1 | Slightly oleophilic, lyophobic | 93 |

| PE | 3 | 3 | 2 | 5 | 3 | Oleophobic, hydrophile | 150 |

| NY | 3 | 5 | 4 | 1 | 1 | Slightly oleophilic, lyophobic | 150 |

| PT | 2 | 1 | 1 | 1 | 1 | Oleophobic, lyophobic | 260 |

In general, for filtrates with a higher polarity such as acid-alkali and salt, polypropylene (PP) will do. For filtrates with lower filtrate such as solvent, polyester (PE) or Nylon (NY) will be the right choice.

| Specification | Gram Weight (g/m2) | Thickness(㎜) | Density (g/㎝3) | Particle dia. (μm) | Pore Volume (%) |

| 1μm | 500 | 1.8 | 0.31 | 1 | 78 |

| 3μm | 450 | 1.7 | 0.21 | 3 | 80 |

| 5μm | 400 | 1.9 | 0.21 | 5 | 85 |

| 10μm | 400 | 2.1 | 0.19 | 10 | 86 |

| 25μm | 400 | 2.5 | 0.16 | 25 | 88 |

| 50μm | 400 | 2.9 | 0.14 | 50 | 90 |

| Breaking elongation: longitudinal: 89-63 crosswise: 81-56 | |||||

| Operating temperature: continuous (℃)130 Instant (℃)150 | |||||

Filter Bag

Related Product

Filter Bag

Our Service

Professional Pre-sale

Service

Filtration method and

equipment recommendation

Free CAD or 3D

drawing provided

Free phone call

Complete Service

During Sales

On time delivery

Equipment inspection

by photo or video

Secure and standard

package provided

After Sales Service

Installation assist by

phone call or video

Free accessories provide

for maintenance

Engineer sent for

solving onsite problem

Filter Bag

FAQ

Where is your factory?

We have three factories in Sichuan, Hebei, Jiangsu. Because the difference of customer locations, raw material price, factory wages and other considerations. In this way, we can provide the best quality product with lower cost.

Do you have a certification?

Yes. we have ISO/CE/BV/SGS/TUV certificate and patent certificate.

How about the delivery time?

Usually 1-15 days after prepayment is confirmed.

Do you have a design team?

Yes, we have. Providing drawing, electric drawing and others.

What is your payment?

T/T, L/C, Western Union, Paypal.

Can you provide certificate of origin?

yes, we can provide CO as well as FORM E, FOEM F and etc.

Can you accept OEM?

Yes, we could do OEM for you.

Can you send me a sample?

Yes.1-3 days for delivery.