Saudi Arabia + Screw Press + Solid-Liquid Separation

Product: Screw Press

Country: Saudi Arabia

Application: Solid-Liquid Separation

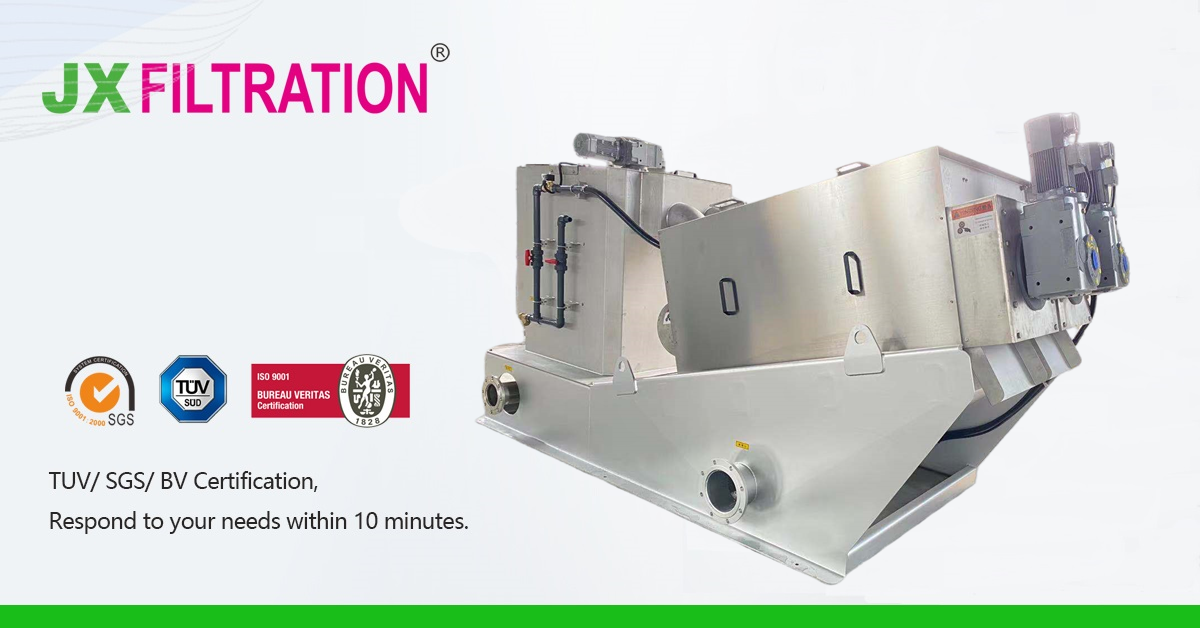

Screw Press is a kind of equipment used for solid-liquid separation, and its full name is spiral stacking sludge dewatering machine. The following mainly introduces its structural composition.

1. Screw press body: It is composed of a fixed ring, a floating ring, a spiral shaft, a screw, a gasket and several connecting plates. The fixed rings are connected together by six screws. Gaskets and floating rings are installed between the fixed rings. The fixed rings and the floating rings are made of wear-resistant materials. The spiral shaft passes between the fixed ring and the floating ring. The floating ring is sleeved on the spiral shaft.

2. Spiral shaft: It is composed of a shaft and spiral blades. The shaft is welded by a shaft and a hollow shaft. When resisting welding, the shaft and the hollow shaft are first welded, and then rough turning is performed after welding to ensure the coaxiality of the shafts at both ends. Then the spiral blades and the shaft are welded by full welding.

3. Drive device: It is the power source of the equipment, usually using a motor with superior performance, the motor protection level is IP54, the insulation level is F, and it meets the IEC standard.

4. Filtrate tank: It is welded by plates and used to collect the filtrate filtered by the main body of the screw stack. The filtrate tank is connected to the frame by screws on all sides, and a flange is provided on the side of the filtrate tank for connection with external equipment.

5. Mixing system: It is mainly used to fully mix the sludge and the reagent to form alum flowers that enter the main body of the screw stack for squeezing and dehydration.

The operation of the screw press is simple. It is linked to the medicine soaking machine, mud feed pump, dosing pump, etc. through the electric control cabinet to achieve 24-hour continuous unmanned operation. It's daily maintenance time is short and maintenance operations are simple.

After-Sale Services

- Quality guarantee: 12 months after the equipment having been operated.

- Satisfied after-sell service: free maintenance and inspection.

- Detailed installation instructions, CAD drawing and product qualification certificate.

Any Requirements, Contact Us Now!

Nina

Email/Teams: nina@filtrationchina.com

Mobile/WhatsApp/WeChat: +86 17269571060