Netherlands + Decanter Centrifuge + Juice Production

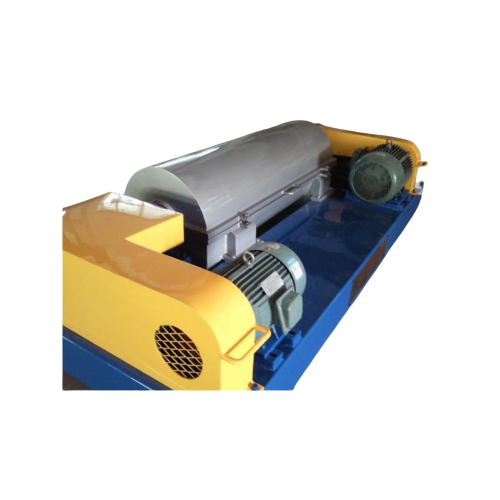

Product: Decanter Centrifuge

Country: Netherlands

Application: Juice Production

In the juice production process, Horizontal Decanter Centrifuge is a key solid-liquid separation equipment, which is mainly responsible for the precise clarification and component purification of juice. JX Filtration's horizontal spiral discharge centrifuge achieves efficient separation through differential centrifugal force. Its application can be divided into three stages:

Primary clarification (removal of 20-50μm particles)

- In the coarse filtered juice (containing pulp particles 0.5-3mm) after crushing and squeezing, the suspended matter is quickly settled by the centrifugal field.

- Equipped with a 316L stainless steel conical drum, it can separate solid phases with a specific gravity difference of ≥0.05g/cm³.

Refined purification (5-20μm ultrafine separation)

- The secondary series system achieves submicron separation and removes colloidal substances (such as pectin and protein).

- The separation accuracy is precisely controlled by variable frequency speed regulation (0-4000rpm stepless regulation), and the transmittance is increased to more than 95%NTU.

Extraction of high value-added components

- Gradient centrifugation technology separates the essential oil phase in citrus juice.

- Specially designed for 0.1-0.3mm seed separation in berries (blueberries/blackcurrants), with a crushing rate of <0.5%.

Typical application scenarios

- NFC juice production: retain heat-sensitive nutrients in the cold crushing process, with a vitamin C loss rate of <3%.

- Pretreatment of concentrated juice: reduce pectin content and avoid evaporator scaling.

- Recycling of pomace: recover >95% free polyphenols from apple pomace.

Tell us your specific raw materials (such as citrus/berries/tropical fruits) and production capacity requirements, and we can provide customized drum aspect ratio and differential configuration solutions.

After-Sale Services

- Quality guarantee: 12 months after the equipment having been operated.

- Satisfied after-sell service: free maintenance and inspection.

- Detailed installation instructions, CAD drawing and product qualification certificate.

Any Requirements, Contact Us Now!

Nina

Email/Teams: nina@filtrationchina.com

Mobile/WhatsApp/WeChat: +86 17269571060