Indonesia + Diaphragm Filter Press + Sludge Dewatering

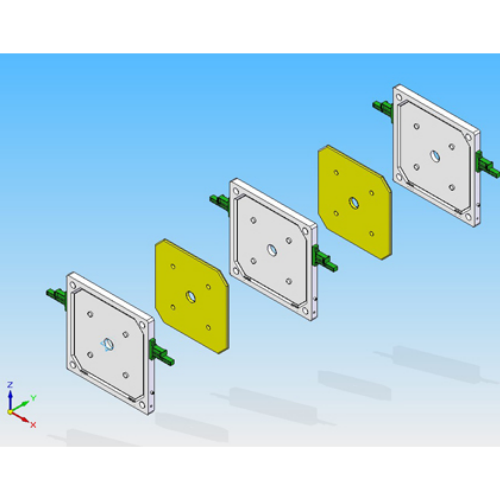

Product: Diaphragm Filter Press

Country: Indonesia

Application: Sludge Dewatering

Diaphragm Filter Press plays a key role in the treatment of cold rolling mill sludge. It is mainly used to efficiently dehydrate the oily and iron-containing sludge generated during the cold rolling production process, and convert it into a filter cake with a low moisture content, which is convenient for transportation, disposal or resource utilization. The following is its application process and key points.

The process of Diaphragm Filter Press to treat cold rolling sludge:

- Sludge conditioning: The purpose is to destroy the stable colloidal structure of the sludge, improve its dehydration performance, and improve the filtration efficiency.

- Feed pumping: The conditioned sludge is pumped into the plate and frame filter press by a high-pressure feed pump. High pressure is the key to ensuring the filtration speed and the moisture content of the final mud cake.

- Filter pressing: The sludge enters the closed filter chamber surrounded by the filter plate and filter cloth under the action of the pump pressure. The filtrate is discharged through the filter cloth, and the solid particles are trapped in the filter chamber to form a filter cake.

- Unloading: After the pressing and blowing are completed, the pressing pressure is removed and the plate frame is loosened. The dehydrated mud cake automatically falls off under the action of gravity.

- Filter cloth cleaning: After unloading, the filter cloth cleaning system is usually started automatically or manually to wash away the residual sludge particles and oil.

- Filtrate and press liquid treatment: The discharged filtrate and press liquid usually contain a certain concentration of oil, COD, SS and other pollutants, which need to be returned to the front end of the sewage treatment system for treatment.

Advantages of Diaphragm Filter Press in treating cold-rolled sludge:

- High dehydration efficiency: Especially for models with diaphragm pressing, extremely low mud cake moisture content can be obtained.

- Strong processing capacity: It can handle complex cold-rolled sludge with high viscosity, fine particles and oil.

- Good mud cake quality: The mud cake is dense, well-formed, and not easy to stick to the filter cloth, which is convenient for subsequent transportation, landfill, incineration or resource utilization.

- Flexible operation: The processing effect can be optimized by adjusting parameters such as feed pressure, pressing pressure and time, and agent dosage.

Diaphragm Filter Press, especially high-pressure automatic diaphragm filter press, has become the mainstream and preferred technology for cold press sludge dewatering treatment due to its excellent dewatering performance, strong adaptability to complex sludge and good mud cake quality.

After-Sale Services

- Quality guarantee: 12 months after the equipment having been operated.

- Satisfied after-sell service: free maintenance and inspection.

- Detailed installation instructions, CAD drawing and product qualification certificate.

Any Requirements, Contact Us Now!

Nina

Email/Teams: nina@filtrationchina.com

Mobile/WhatsApp/WeChat: +86 17269571060