France + Disc Centrifuge + Food Industrial

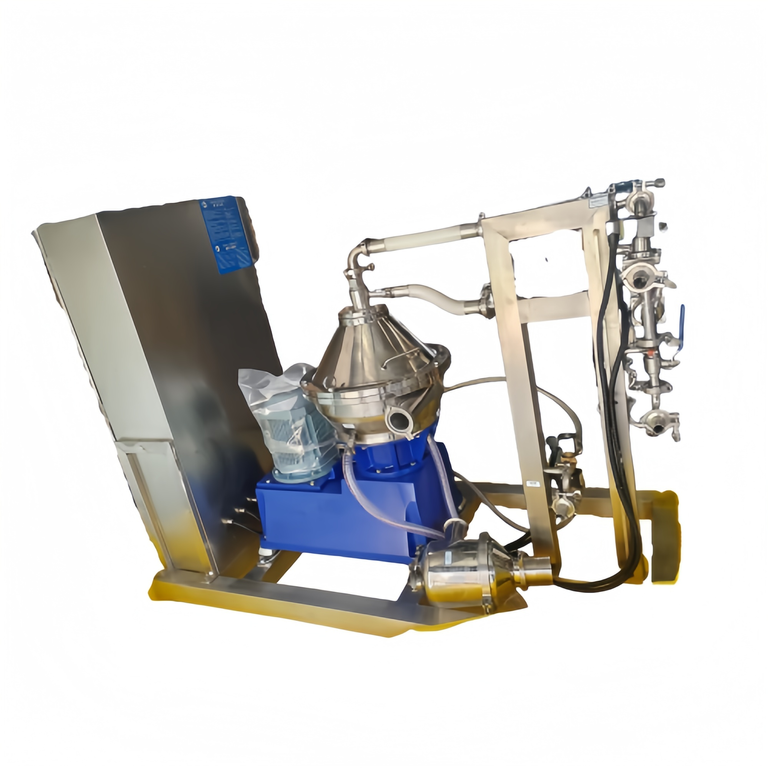

Product: Disc Centrifuge

Country: France

Application: Food Industrial

Disc Centrifuge is a device that uses the centrifugal force generated by high-speed rotation to continuously separate, clarify or concentrate liquid mixtures. Its core component is a stacked conical disc group, which can greatly increase the effective sedimentation area and significantly improve the separation efficiency. It has a wide range of applications in many industrial fields. The following mainly introduces its application in the food and beverage industry.

1. Dairy products

- Milk skimming: separation of fat (cream) and skimmed milk in whole milk.

- Whey skimming/clarification: separation of fat and solid particles in whey after cheese making.

- Milk/dairy beverage standardization: precise adjustment of fat content.

- Milk/dairy beverage clarification: removal of impurities, somatic cells and bacteria (pretreatment before pasteurization)

2. Juice

- Clarification: removal of turbid substances such as pulp, pomace, colloid, starch, etc., to produce clear and transparent juice.

- Concentration: separation of water in juice to increase concentration.

3. Oils and fats

- Vegetable oil refining: Separate impurities such as gelatin, soap stock, and water in the refining steps such as degumming, neutralization, dewaxing, desoaping, and washing.

- Fish oil/animal oil purification: Remove solid impurities, water and some free fatty acids.

4. Wine/beer

- Beer clarification: Remove yeast, cold condensate, hop resin, etc. to improve beer stability and transparency.

- Wine clarification: Remove dead yeast, tartrate, protein, etc. to improve wine stability.

5. Starch and sugar

- Starch washing and refining: Separate impurities such as protein, fiber, cell fluid, etc. from starch milk.

- Sucrose/beet juice clarification: Remove impurities such as suspended solids and colloids.

Disc centrifuge is an indispensable key separation equipment in modern industry, especially in the fields of food, chemical industry, pharmaceutical industry and environmental protection. Its specific application will choose different models according to industry and process requirements.

After-Sale Services

- Quality guarantee: 12 months after the equipment having been operated.

- Satisfied after-sell service: free maintenance and inspection.

- Detailed installation instructions, CAD drawing and product qualification certificate.

Any Requirements, Contact Us Now!

Nina

Email/Teams: nina@filtrationchina.com

Mobile/WhatsApp/WeChat: +86 17269571060