What is Diaphragm Filter Press?

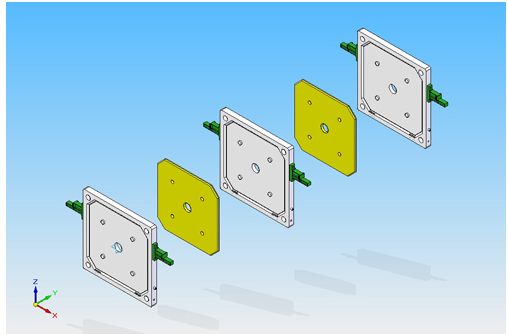

Diaphragm filter press, is composed of diaphragm plate and chamber filter plate arrangement of the filter chamber, in the pressure of the infusion pump down slurry into the filter chamber, through the filter media (filter cloth) will be separated from the solid-liquid, trip filter cake, and then to the diaphragm cavity into the compressed air, the solids in the filter chamber fully pressed to reduce the water content.

Especially for the filtration of viscous materials, which require low water content of the filter cake, its unique superiority is more obvious. The automatic pulling plate adopts microcomputer controller, PLC and touch screen control to perform various operations on the filter press (such as filter plate pressing, liquid collecting plate merging and opening, loosening the filter plate, water flushing, etc.), and leaves a remote control interface to enable remote automatic operation and control.

The main difference between diaphragm filter press and ordinary chamber filter press is that two elastic membranes (compound rubber diaphragm is the whole diaphragm) are added on both sides of the filter plate. During the operation, when the feeding is finished, the high pressure fluid medium can be injected into the diaphragm plate, at which time the whole diaphragm will bulge up and press the filter cake.

The diaphragm filter press is applied to sludge and sewage treatment, and the water content of the filter cake has been achieved below 30%, compared with the traditional chamber filter press, the solid content of the filter cake can be increased by more than 2 times, and the transportation cost of the filter cake is greatly reduced, and the filter cake can enter the power plant for direct combustion.

For different diaphragm materials, the new generation of diaphragm filter presses can be divided into rubber diaphragm type and polymer elastomer diaphragm type diaphragm filter presses.

- The rubber diaphragm filter press is ideal for filtering materials with weak acids, weak bases, and non-organic solvents. The rubber diaphragm filter press changes the shortcomings of the past split fixed type to save energy consumption after feeding, and the new design makes the rubber diaphragm tympanic membrane _ plus full, the use of pressure and air volume than Fully automatic diaphragm filter press - reinforced polypropylene type smaller, in the case of the same air source gas volume, rubber diaphragm drum membrane is three times the polymer diaphragm drum membrane, can greatly reduce energy consumption.

- Polymer elastomer diaphragm filter press is used in strong acid, strong alkali and organic solvent materials, the performance is relatively _ ideal and the service life _ long. Its press form is divided into gas (air) press and liquid (water) press, which can meet the needs of different industries. According to customer needs press components can be configured _ and ordinary level, control can be used PLC and human-machine interface. For general materials, after 3-15 minutes of diaphragm drum, _ can _ play the role of pressing and dewatering. For some special materials, the segmental pressing method of low-pressure pressing followed by high-pressure pressing can also be used.

Application

Diaphragm filter press has the advantages of high pressing pressure, good performance, easy maintenance, safety and reliability, etc. It is widely applied in metallurgy, gas, paper making, coking, pharmaceutical, food, brewing, fine chemical industry, etc.

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160