Fully and Semi-submerged Rotary Disc Filter

The Rotary Disc Filter is one of the most advanced filters in the world. It is mainly used for cooling circulating water treatment, and reuse of wastewater after advanced treatment.

Application

Reused as cooling water and circulating water after filtration: inlet water quality SS <80mg/L or less, outlet water quality SS <10mg/L.

- Set after the conventional activated sludge method, delayed aeration method, SBR system, oxidation ditch system, trickling filter system, oxidation pond system.

- It can be used in the following fields: @Removal of total suspended solids @ Combined with chemical addition to remove phosphorus @ Remove heavy metals, etc.

- The rotary disc filter is used to filter the outlet of the activated sludge final sedimentation tank. The designed water quality: inlet SS: 20mg/L (impact load can withstand 80-100mg/L), outlet SS<5 smg/L, turbidity <3NTU. The actual outlet water has higher quality, and the turbidity of the outlet is generally around 1.

The rotary disc filter is divided into internally fed type and externally fed type according to the water inflow form. The internally fed type is semi-submerged and the externally fed type is fully submerged.

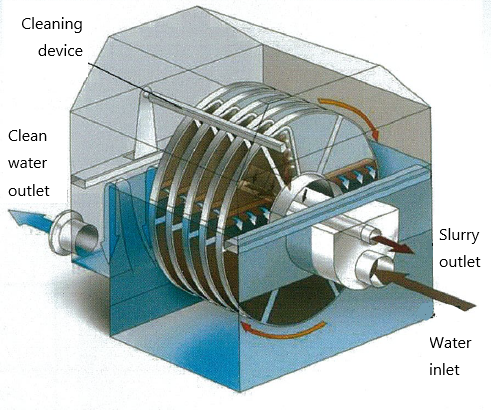

Fully Submerged Rotary Disc Filter

Working principle

The Fully Submerged Rotary Disc Filter consists of a central rotating drum, filter discs, backwashing system and supporting electrical control system. The filter disc is fixed around the central drum and has a connection hole with the central drum. The raw water (sewage) flows into the rotating cartridge through the filter cloth on the disc. The filter cloth is a special fiber filter cloth with a minimum filter pore size of 10 µm. After the raw water is filtered by the filter cloth, the clean water flows into the drum and is discharged out of the system from the outlet of the drum. As the filtration progresses, the trapped impurities on the outside of the filter cloth continue to increase, the filter pressure difference increases accordingly, and the amount of water passing through the filter cloth decreases. When the impurities accumulate to a certain level and the filter tank level reaches the set value, the backwashing device starts to run to backwash out the impurities accumulated on the outside of the filter cloth. After backwashing, the sewage impurities are sucked into the sewage pipe and then discharged out of the device. During backwashing, the disc rotates until the filter cloth has been cleaned. The backwashing stops and re-enters the static filtering process to operate in this cycle.

Features

- The effluent quality is good and stable.

- Novel design and impact load resistance.

- The equipment is simple and compact, with few auxiliary equipment, and low investment in the entire filtration system.

- The operation is automated, so the operation and maintenance are simple and convenient.

- The head loss is much smaller than that of the sand filter.

- The footprint is much smaller than other filters.

- The filter cloth rotary disc filter is easier to install than the granular filter tank.

- The design period and construction period are short.

- Low endurance requirements for ground bases, and low investment in equipment bases. It is especially suitable for the upgrading and transformation of established sewage treatment plants.

Technical Data

- Inlet water quality: SS≤30 mg/L (shock load 80 mg/L)

- Outlet water quality: SS≤10 mg/L

- Head loss: 300 mm in the filter tank

- Average filtration speed: 10 m/h

- Backwash water volume: ≤1%

- Disc diameter: 2.2m 2.5m 3 m

- Filter cloth material: microfiber

Semi-submerged Rotary Disc Filter

Working Principle

The semi-submerged turntable filter consists of a central rotating drum, a disc, a backwash system and a supporting electrical control system. The disc is fixed on the center drum circumference surrounding the well, the well and the central drum have connection holes. The raw water (sewage) flows out of the filter disc through the central drum. The filter screen is a 316L stainless steel mesh with a minimum filter pore size of 10 µm. After the raw water is filtered through the filter, the clean water flows into the pool. As the filtering progresses, the trapped impurities inside the filter continue to increase, the filter pressure difference increases, and the amount of water passing through the filter decreases. When the impurities accumulate to a certain level, the liquid level of the filter drops to the set value, and the backwashing device starts to operate to backwash out the impurities accumulated on the inside of the filter. After flushing, the sewage impurities are flushed into the sewage pipe, and then discharged out of the device. During backwashing, the turntable rotates until the filter screen has been cleaned, the backwashing stops, and the static filtering process is re-entered to cycle operation.

Features

- The effluent quality is good and stable.

- Novel design and impact load resistance.

- The equipment is simple and compact, with few auxiliary equipment, and low investment in the entire filtration system.

- The operation is automated, so the operation and maintenance are simple and convenient.

- The head loss is much smaller than that of the sand filter.

- The footprint is much smaller than other filters.

Technical Data

- Inlet water quality: SS≤20 mg/L (shock load 80 mg/L)

- Outlet water quality: SS≤5 mg/L

- Head loss: 300 mm in the filter tank

- Average filtration speed: 10 m/h

- Backwash pressure: 0.7 MPa

- Backwash water volume: ≤1%

- Disc diameter: 2.2m 2.5m

- Filter cloth material: SS316

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160