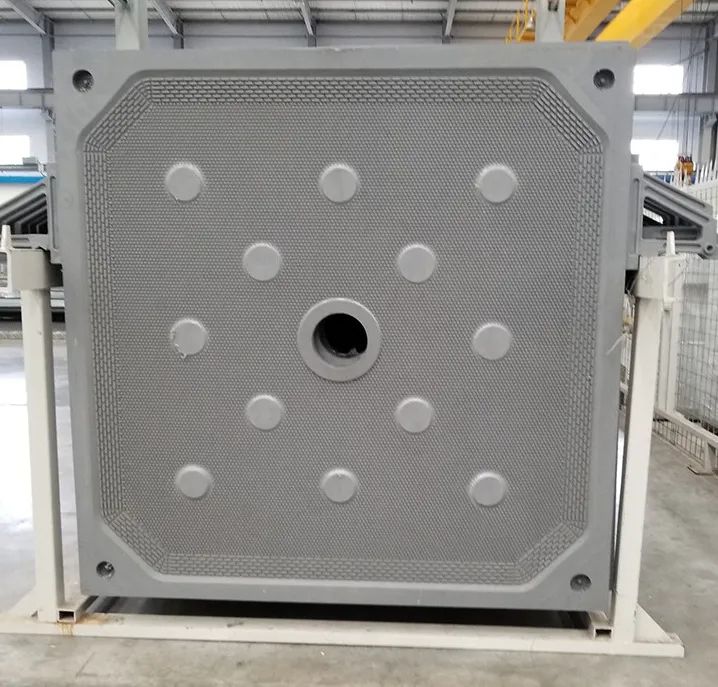

The Filter Plate Selection of Filter Press

The selection of material for the filter plate in Plate and Frame Filter Press is crucial. Considering the working environment of the filter plate, the sludge contains corrosive substances with certain corrosion resistance, and the repeated extrusion and impact during the working process, the filter plate should have a certain strength and also a certain wear resistance.

The materials of filter plates commonly used at present:

- PP polymer polypropylene, is currently the most commonly used. This material, for a variety of acid and alkali tolerance is very good, including the strongest acid hydrofluoric acid, have a good acid resistance. Its working temperature is relatively small, cod June in practice found that its most resistant to short time of 70 ° material.

- PVDF, is acid resistance, temperature resistance of the best organic materials, the normal temperature resistance can reach about 150 °, but alkali resistance is very poor.

- Natural rubber filter plate, good elasticity, but poor strength. Especially the diaphragm, with natural rubber is still good.'

- Aluminum filter plate, the lightest metal filter plate, but relatively poor acid resistance.

- Cast iron filter plate, heavy weight, poor acid resistance, extremely high temperature resistance. Only the sealing surface, in fact, must also use organic materials to do, there are certain limitations.

- Stainless steel filter plate, acid and alkali resistance is better, but the price is the largest of all filter plates. The material itself is expensive, and the machining is very time-consuming.

In summary, taking into account the addition of the filter plate to have acid and alkali resistance, with a certain strength and wear resistance, the filter plate material should be selected stainless steel.

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160