6 kinds of Pipeline Filter

Pipeline Filters including Y-type filter, T-type filter, basket filter, Manual brush self-cleaning filter, Magnetic filter, Backwash filter.

The Y-type filter is a rough filter for pipelines, which can be used to filter large particles of liquid, gas or other media. It can be installed on the pipeline to remove the larger solid impurities in the fluid to ensure the equipment (including compressors, pumps, etc.) and meters can be operated normally and safely.

When the fluid enters the filter cylinder with a certain specification filter screen, its impurities are blocked, and the clean filtrate is discharged from the filter outlet. When cleaning is required, users only need to take out the detachable filter cartridge and reload it after cleaning which is extremely convenient to use and maintain.

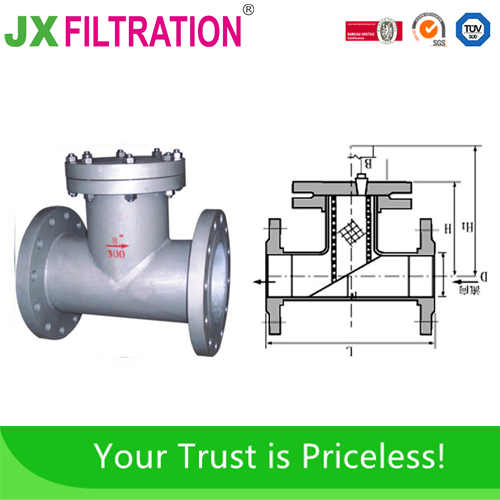

T-type filters are divided into direct-flow type and baffle type. Baffle-type T-type filters are generally installed at right angles to the pipeline and have the characteristics of small footprint, easy cleaning, and cost-saving. It can be installed on the pipeline to remove the larger solid impurities in the fluid to ensure the equipment (including compressors, pumps, etc.) and meters can be operated normally and safely.

When the fluid enters the filter cylinder with a certain specification filter screen, its impurities are blocked, and the clean filtrate is discharged from the filter outlet. When cleaning is required, users only need to take out the detachable filter cartridge and reload it after cleaning which is extremely convenient to use and maintain.

It is mainly composed of connecting pipe, cylinder, filter basket, flange, flange cover and fasteners. It is installed on the pipeline can remove the larger solid impurities in the fluid, and the machinery and equipment (including compressors, pumps, etc.) and instruments can work and run normally and ensure safe production.

When the liquid enters the filter basket through the cylinder, the solid impurity particles are blocked in the filter basket, and the clean fluid passes through the filter basket and is discharged from the filter outlet. When cleaning is required, unscrew the screw plug at the bottom of the main pipe, drain the fluid, remove the flange cover, and reinstall it after cleaning.

Manual brush self-cleaning filter

Manual brush filter is a kind of semi-automatic cleaning filter, using brush and brush frame of the filter screen to brush off the dirt, impurities and other particles on the filter screen, and then discharge it through the sewage valve. The cleaning process can be carried out during the working process of the filter, without the need to cut off the flow and no affect on the normal operation of the equipment.

It is suitable for various water supply systems, process water systems and industrial cooling water systems, especially non-stop systems that run continuously for 24 hours. It can filter out various mechanical impurities in the water to ensure the safe and reliable operation of system equipment.

Magnetic filters are widely used in pigments, dyes, petrochemicals, pharmaceuticals, food, plastics and other industries. They can effectively remove magnetic metal impurities during the liquid slurry transportation process, reduce the iron ion content in the product, and improve the quality of the product. It has the advantages of small size, light weight, convenient installation and operation.

In the process of liquid slurry transportation, when the slurry passes through the filter, it is subjected to the magnetic action of the strong magnetic rod, and the iron impurities in the slurry are adsorbed on the magnetic rod sleeve, which greatly reduces the iron impurities in the slurry and ensures the next process can effectively control the iron impurity content.

The automatic flushing filter is widely used in drinking water, wine, oil, chemical and other industries because of its high efficiency and convenience.

When the liquid containing solid impurities enters the automatic flushing filter through the water inlet, the impurities are trapped on the surface of the filter element causes the pressure drop on both sides to increase. When the pressure difference between the two sides of the filter element reaches the set value, the pressure difference controller transmits the corresponding signal to the electric valve through the control cabinet, the electric valve opens, and the hydraulic or electric motor drives to discharge. After draining for a period of time, the pressure difference between the inlet and outlet of the filter is reduced, and the electric valve is automatically closed to complete the backwashing process. This process is repeated to achieve the filtering effect. The automatic backwash filter produced by JX Filtration can be customized according to the specific requirements of customers (pressure difference control, time control, manual control, etc.).

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160