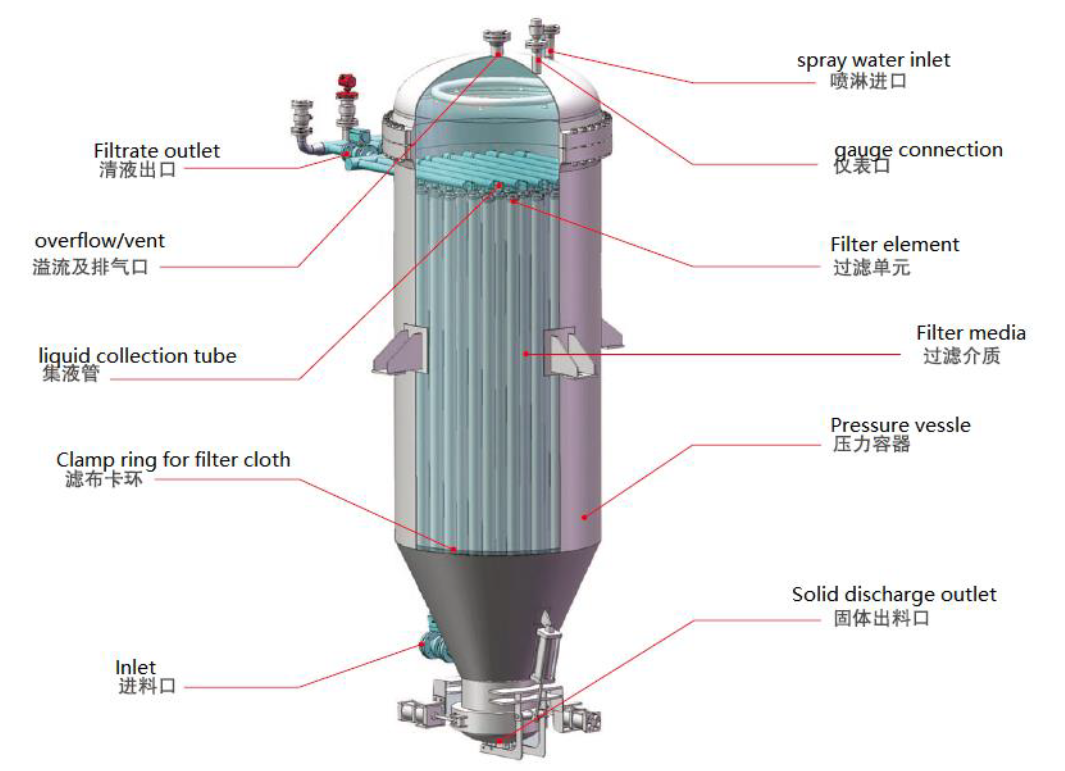

Automatic Candle Filter

It is widely used in a variety of special filtration conditions such as high impurity content, viscous liquid, ultra-high precision, etc.

Automatic Candle Filter It has the advantages of closed operation, large filter area, high dirt treatment capacity, easy to back-blow filter cake. The filter five functions: direct filtration, pre-coating filtration, slurry concentration, filter cake recovery, filter cake washing.

Working Principle

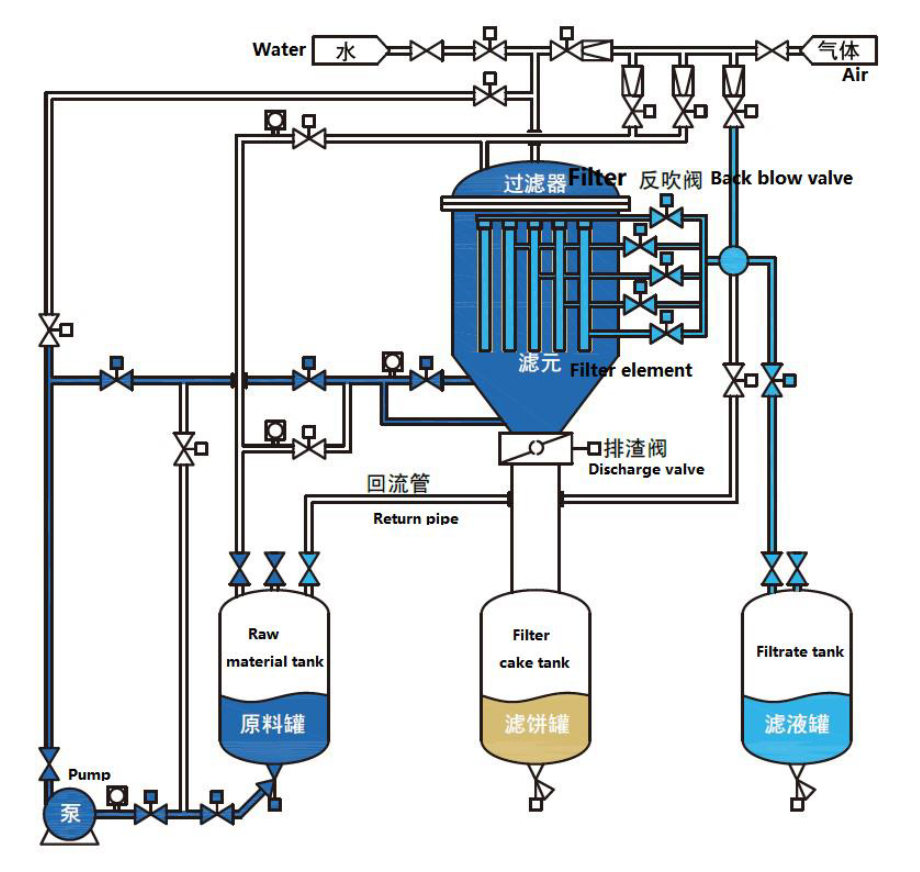

Closed candle filter is a combination of filter which combines several filter elements in a closed container to filter cloth (or other filter media) on the outer casing of the filter element. During filtration, the material feeds into the filter by a pump. During filtration, the material passes through the filter medium and enters the center of the filter element and is discharged at the outlet of the cleaner solution. Before forming a filter cake on the candle element of the filter, the material needs to be circulated and filtered. Until a certain thickness of filter cake is formed on the candle core, the cycle filtration is over and the normal filtration begins.

After the filter operates normally for a period of time, when the filter cake on the candle core reaches a certain thickness, the PLC sends the command signal to control the feed (stop). Then drains the residue in the filter. After draining, the PLC signal controls the back-blowing port (compressed air, nitrogen or saturated steam) to blow the filter cake off, after which the filter discharge port is opened for slag discharge. After the slag discharge, close the slag discharge outlet and return to the initial state before filtration, ready for the next round of filtration.

Features

- It can be directly filtered, pre-coated filtered, slurry concentrated, filter cake recycled and washed.

- PLC automaticly controls liquid filling, pre-filtration, filtering, residue discharge, slag discharge and backblowing processes.

- Be competent for high precision and solid content (up to 5 %), high viscous applications.

- The ulti-level filtering precision up to 0.22 micron.

- Group design of filter elements to reduce air consumption backblow and isolate damaged filter elements.

- The spacing of filter elements can be adjusted to suit different filter cake thickness requirements.

- Closed filtration to control pollution, suitable for highly corrosive, volatile or hazardous liquids.

- Provide drying design to recover drier filter cakes.

- Provide tail filtration design to reduce material waste.

- The main body is static component with dynamic backblowing, low failure rate and low running cost.

Technical Data

|

Filtration area (㎡) |

2-60 |

|

Optional Precision (um) |

0.5-800 |

|

Housing material |

304,316L, CS |

|

Applicable Viscosity (cp) |

1-2000 |

|

Applicable temperature (℃) |

1-200 |

|

Design Pressure (MPa) |

0.6-1.0 |

|

Optional Cleaning Start Mode |

Time/ Differential Pressure |

Application

- Petrochemical industry: amine solution, catalyst recovery, sulfuric acid, polyol, titanium dioxide, PTA particles, polyglycol, potassium carbonate, epoxy resin.

- Biopharmaceuticals: fermentation extract, antibiotics, antibiotics, streptomycin, citric acid.

- Food and beverages: apple juice, grape juice, raw syrup, Fructose-glucose syrup, glucose syrup, sucrose, beer, olive oil, palm oil, soybean oil, corn oil, gelatin.

- Sewage treatment: electronic wastewater treatment, printing and dyeing wastewater treatment, chemical wastewater treatment, etc.

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160