What is candle filter principle?

Application: fine chemicals, plastics, fuels, electroplating, grease, lubricants, ceramics, glass, pharmaceuticals, sugar, etc.

Industry, and solid recovery applications of metals, catalysts, etc.

Features of automatic candle filter

- Completely airtight filtration, no leakage, no environmental pollution.

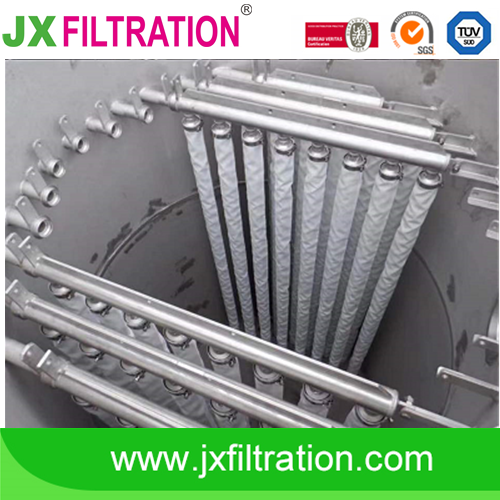

- The filter element design adopts a duplex plum structure (internal stainless steel frame, external filter cloth)

- Complete filtration at one time.

- The filter cake can be dried to obtain the greatest economic benefits

- Adopt gas blow back slag discharge, slag discharge is clean and fast, suitable for a variety of viscous materials

- The entire filtering process can be fully automated.

Working principle of automatic candle filter

In a closed container, combine multiple porous filter elements, the filter cloth (or other filter media) on the outer cover of the filter element. And use the pump to deliver the slurry into the filter during filtration, and the liquid phase in the slurry passes through the filter medium. It enters the center of the porous filter element and is collected and discharged from the clear liquid outlet. Before the filter cake layer is formed, the discharged "clean liquid" is returned to the raw material slurry inlet and sent to the filter for circulating filtration until the filter cake layer is formed (which can meet the filtering requirements ). A signal is provided to control the clean liquid to no longer circulate, and it is sent to the next process through a three-way valve for normal filtration.

After normal filtration for a period of time, when the filter cake layer reaches a certain thickness, a signal is provided to control the feed (stop). Then the residual liquid in the filter is drained, and a signal is provided to control the blowback port (compressed air, nitrogen or saturated steam) perform back-blowing to make the filter cake fall off. After back-blowing for a certain period of time, stop back-blowing, provide a signal to open the filter slag outlet, close the outlet after the slag discharge is completed, and return to the initial state before filtering. Ready for the next round of filtration.

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160