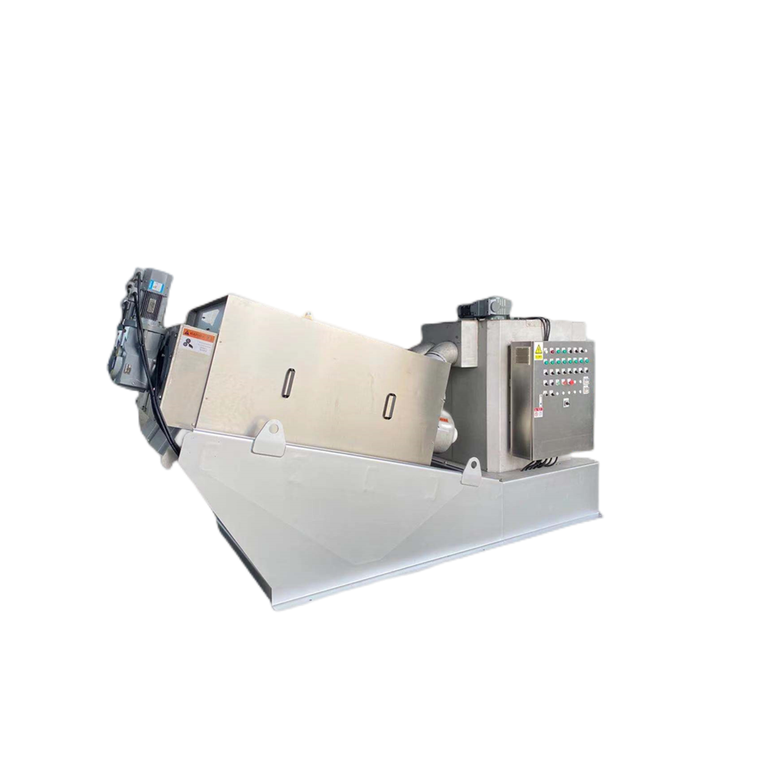

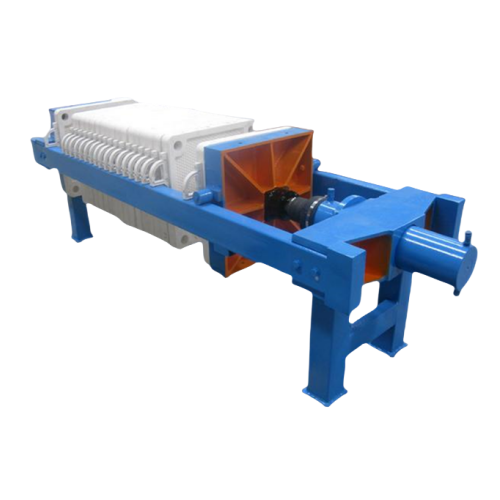

What's the Difference between Screw Press and Filter Press?

As a technical expert in industrial solid-liquid separation equipment, what are the similarities and differences between JX Filtration's screw presses and Filter press in sludge treatment? A brief introduction follows.

Similarities

Both screw presses and filter presses belong to the category of "solid-liquid separation equipment that relies on external force extrusion." When treating sludge, they share the following commonalities:

Basic Principle:

Both use mechanical pressure (such as screw extrusion or hydraulic pressure) to squeeze out water from the sludge, achieving solid-liquid separation, thereby reducing the sludge volume and water content, facilitating transportation, disposal, or resource utilization.

Application Scenarios:

Widely used in municipal wastewater treatment and industrial wastewater treatment (such as chemical, food, and paper industries) for sludge dewatering, suitable for various types of sludge (such as biological sludge and physicochemical sludge).

Core Objectives:

Improve dewatering efficiency, reduce treatment costs, and support environmental compliance. JX Filtration's equipment in this category emphasizes energy efficiency and automation design to enhance the user experience.

Differences

Despite similar objectives, screw presses and filter presses differ significantly in their working principles, operation methods, and performance. The following are key differences based on JX Filtration's technical standards:

Working Principle:

Screw presses operate continuously: sludge is gradually squeezed and dewatered by the rotating screw shaft, with water discharged through the screen openings, resulting in a continuous output.

Filter presses are typically intermittent: sludge is pumped between filter plates and pressed by hydraulic or mechanical pressure to form a filter cake, which is then discharged manually or automatically.

Dewatering Effect:

Screw presses produce sludge with a relatively high moisture content (typically 75%-85%) after dewatering, but have a large throughput, making them suitable for medium to low dryness requirements.

Filter presses produce sludge with a lower moisture content (can be reduced to 60%-70%) and higher dryness, suitable for scenarios requiring strict volume reduction.

Automation Level:

Screw presses have a high level of automation, can operate continuously, reduce manual intervention, and are suitable for large-scale processing. JX Filtration's screw presses often integrate PLC control.

Filter presses have a highly cyclical operation, requiring batch loading and unloading. Automated versions are available, but overall, they rely more on manual scheduling.

Suitable sludge types:

Screw presses are more suitable for sludge with low viscosity and good flowability (such as municipal sludge), and are less adaptable to sludge with high oil or fiber content.

Filter presses have a wide range of applications and can handle high-viscosity, difficult-to-dewater sludge (such as industrial hazardous waste sludge). The effect can be optimized by adjusting the filter cloth.

Both screw presses and filter presses have their advantages: Screw presses excel in continuous operation and high efficiency, suitable for applications with large throughput and high automation requirements; filter presses excel in high dryness and flexibility, suitable for applications with strict standards for dewatering dryness. JX Filtration offers various models of both types of equipment, and can customize the selection based on sludge characteristics, throughput, and budget.

Any requirements, contact us now!

Nina

Email: nina@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 172 6957 1060