What is Filter Press?

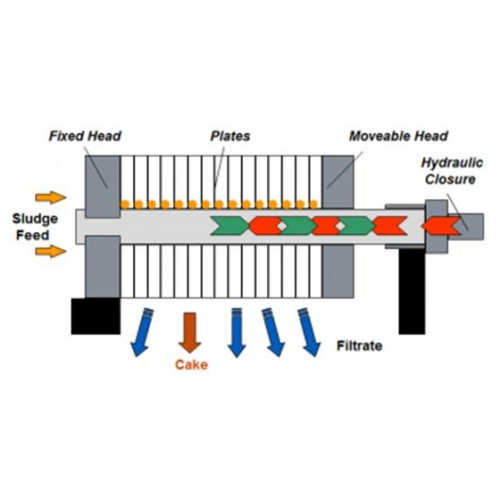

A filter press is a filtering device that uses pressure difference as a driving force to separate the solid and liquid of a suspension. Simply put, it squeezes a slurry mixture into a relatively dry solid filter cake and a relatively clear filtrate.

The following are the working principles and main classifications of filter presses.

1. Working principle (taking a common chamber filter press as an example):

- Compression: The compression device pushes the movable compression plate to press all the filter plates tightly together to form a series of sealed filter chambers.

- Feeding: The suspension is pumped into each filter chamber by a high-pressure pump through the feed port. The feed pressure is the main driving force for filtration.

- Filtration: Under pressure, the filtrate passes through the filter cloth and flows along the grooves on the surface of the filter plate to the filtrate outlet for discharge.

- Filter cake formation: As the filtration proceeds, the filter cake continues to thicken in the filter chamber, and the filtration resistance gradually increases. When the filter cake fills the filter chamber or reaches the preset pressure/time, the feeding stops.

- Discharging: The compression device is released and the movable compression plate retreats. The filter plates are pulled apart one by one. The filter cake falls off the filter cloth due to its own weight or with the help of the unloading mechanism, and falls into the collection tank or conveyor belt below to be transported away.

- Cycle: After cleaning or checking the filter cloth, the filter press is re-tightened and the next working cycle begins.

2. Main types:

- Plate and frame filter press: It consists of filter plates and filter frames arranged alternately. The filter frame forms a space to accommodate the filter cake. The structure is simple, but there are many sealing surfaces and the degree of automation is relatively low.

- Chamber filter press: There are only filter plates, no separate filter frames. The concave surfaces of two adjacent filter plates are combined to form a filter chamber. There are few sealing surfaces and it is easy to realize automation.

- Diaphragm filter press: An elastic diaphragm is embedded in the filter plate of the chamber filter press. After the filtration is completed, the diaphragm is bulged with a high-pressure medium, and the filter cake is squeezed for a second time with strong force, which significantly reduces the moisture content of the filter cake.

A filter press is a device that applies pressure to force the liquid in the suspension to pass through the filter cloth and be discharged as filtrate, while the solid particles are retained on the filter cloth to form a filter cake, thereby achieving efficient solid-liquid separation.

Any requirements, contact us now!

Nina

Email: nina@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 172 6957 1060