What are the Advantages of Disc Centrifuge in Chemical Applications?

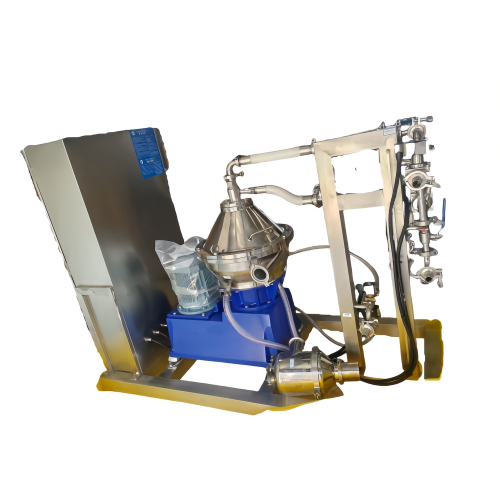

As an efficient and continuous solid-liquid separation equipment, Disc centrifuge is widely used in many fields of the chemical industry. The following mainly introduces its outstanding advantages in chemical applications.

1. Continuous and efficient: It can run continuously for 24 hours, with a large processing capacity, which is particularly suitable for the needs of large-scale continuous production in modern chemical industry.

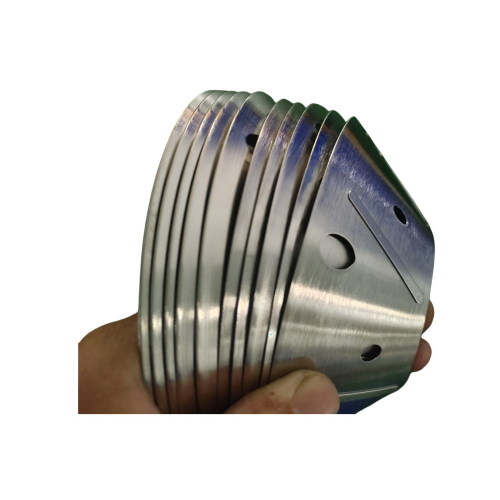

2. High separation accuracy: The powerful centrifugal force field and disc group design can separate micron-level or even submicron-level fine particles and emulsified droplets, and handle systems with very small density differences.

3. Good airtightness: It can be designed into a fully enclosed system to effectively prevent:

- Voc volatilization: When handling volatile organic solvents, reduce losses and environmental pollution.

- Leakage of toxic/corrosive materials: Protect the safety of operators and the environment.

- Oxidation: Protection of air or moisture-sensitive materials.

- Explosion-proof requirements: Suitable for handling flammable and explosive chemical materials.

4. Versatility:

- Can handle solid-liquid two-phase separation (clarification/concentration)

- Can handle liquid-liquid two-phase separation (such as oil-water separation)

- Can handle liquid-liquid-solid three-phase separation (such as oil-water mixture containing a small amount of solid impurities)

5. High degree of automation: easy to integrate into the DCS/PLC control system to achieve automatic start and stop, parameter adjustment, slag discharge control and online cleaning.

6. Strong adaptability: By selecting different materials, disc types, slag discharge methods and operating parameters, it can adapt to various corrosive, high-temperature or high-viscosity chemical materials.

Disc centrifuge is an indispensable separation equipment in the chemical industry. In the broad field from basic petrochemicals to fine chemicals, it solves a series of key process problems such as oil-water separation, catalyst recovery, solvent purification, polymer processing, intermediate purification, etc., and plays a vital role in improving product quality, reducing production costs, realizing resource recycling and meeting environmental protection requirements.

Any requirements, contact us now!

Nina

Email: nina@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 172 6957 1060