What is Filter Press?

Filter press is an industrial device used for solid-liquid separation. It separates the solid and liquid phases by forcing a suspension through a filter medium under high pressure, trapping solids as a filter cake while allowing the liquid to drain through the filter cloth.

Simply put, its working principle is like squeezing a sponge with a very strong force, squeezing the water out of the sponge and leaving behind a dried sponge (solid filter cake).

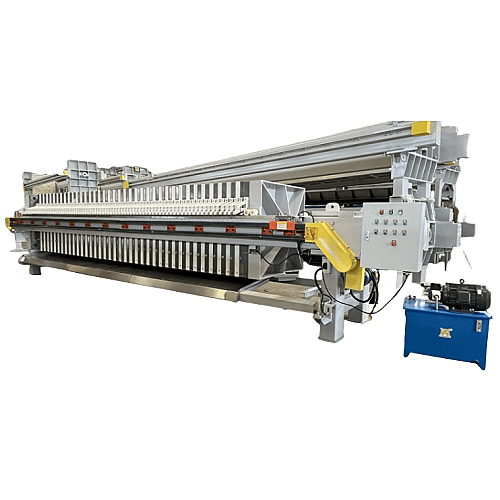

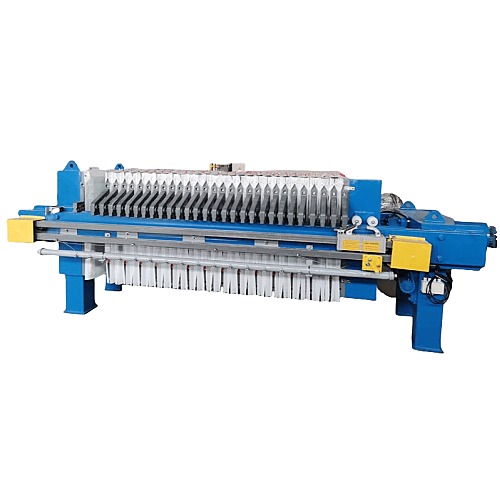

Main Components

A typical filter press consists of the following components:

- Frame: The backbone of the equipment, supporting all other components and withstanding the filtration pressure.

- Filter unit: The core component, typically consisting of multiple filter plates and a filter cloth sandwiched between them. The filter plates are typically square, with a central cavity and grooves on their surfaces to support the filter cloth and guide the filtrate outflow. The filter plates have a central through-hole for material entry. The filter cloth performs the actual filtering, and its pore size determines the size of the solid particles it can retain.

- Clamping mechanism: This clamps the filter plates together to form a closed filter chamber, preventing material from leaking under high pressure. It can be manually, mechanically, or hydraulically driven.

- Hydraulic system: Provides power to the pressing mechanism.

- Control system: Modern filter presses typically use a PLC to automatically control the entire operation process.

Widely used areas:

- Wastewater treatment: Dewatering sludge generated during municipal and industrial wastewater treatment.

- Chemical industry: Separation, purification, and dehydration of products in production processes (such as pigments, dyes, and fertilizers).

- Metallurgy and mining: Dehydration of concentrates and tailings.

- Food and pharmaceuticals: Separation of starch, juice, and fermentation bacteria.

- Ceramics and building materials: Dehydration of clay, glazes, and other materials.

A filter press is a highly efficient solid-liquid separation device that utilizes positive pressure as the filtration force, operating intermittently through a filter cloth. Its core value lies in its ability to process a variety of difficult-to-separate materials, producing a very dry solid cake and a clear liquid. Therefore, it is an indispensable key piece of equipment in many industrial fields, particularly in the environmental protection and chemical industries.

Any requirements, contact us now!

Nina

Email: nina@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 172 6957 1060