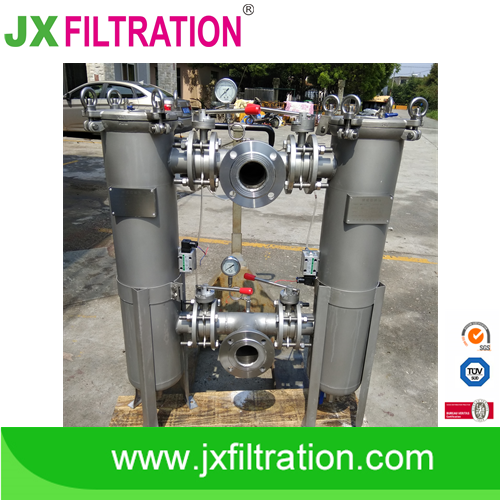

Parallel Bag Filter

The parallel bag filter is also called double bag filter or duplex bag filter. It is composed of two bag filters. It is a single-layer stainless steel welded structure. The inner and outer surfaces are polished. The pipe joints are connected by expansion, and after 0.8Mpa water pressure test, the three-way external thread cock can be opened and closed flexibly. The equipment is compact in structure, convenient in operation and simple in maintenance.

Duplex filter, also known as parallel switching filter, adopts two three-way ball valves, and assembles two single-cylinder filters on a machine base. It is not necessary to stop the filter when cleaning the filter to ensure its continuous operation. It is a filter device for non-stop production lines. First of all, this filter can filter out particles with a particle size of more than 1μm, and can also be used in a single cylinder. Only need to remove the common base, and the other dimensions remain unchanged.

The inner and outer surfaces of the double filter are polished, and the filter cartridge is equipped with a filter bag and a filter bag support basket. The top is equipped with a vent valve to discharge the air in the filter during filtration. The connection between the upper cover and the filter cartridge adopts a quick-opening structure, which is more convenient for cleaning (replacing) the filter bag, and three adjustable feet can make the filter stable on the ground. The connecting pipeline adopts the connection method of live connection or clamp, and the inlet and outlet valve adopts three-way ball valve to open and close, which is pressure-resistant and temperature-resistant, flexible and convenient to operate, and more hygienic without leakage of material liquid.

Application

1. Weak corrosive materials in chemical and petrochemical production, such as: water, ammonia, oil, hydrocarbons, etc.

2. Corrosive materials in chemical production, such as: caustic soda, concentrated dilute sulfuric acid, carbonic acid, acetic acid, etc.

3. Low temperature materials in refrigeration, such as: liquid methane, liquid ammonia, liquid oxygen and various refrigerants.

4. Light industrial food, materials with hygiene requirements in pharmaceutical production, such as: beer, beverages, dairy products, grain, pulp and medical supplies, etc.

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160