Detailed Introduction to Dewatering Screw Press

Application: Municipal sewage, domestic sewage, food, beverages, chemicals, leather, welding materials, paper making, printing and dyeing, pharmaceuticals, electroplating, oil fields, coal mines, wine making, livestock breeding, kitchen wastewater, water plants, power plants, steel plants.

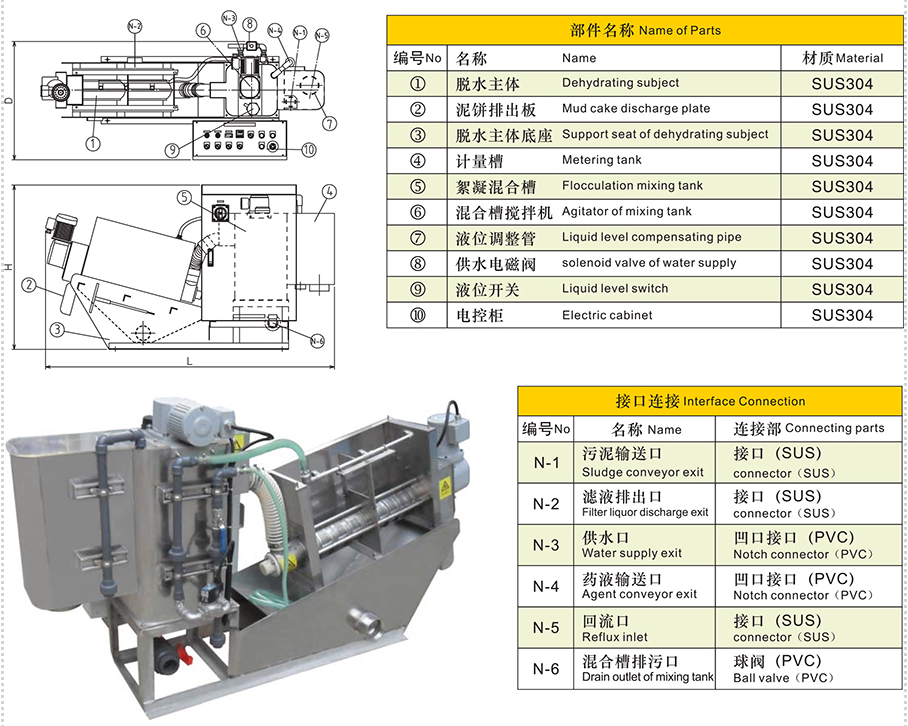

Structure

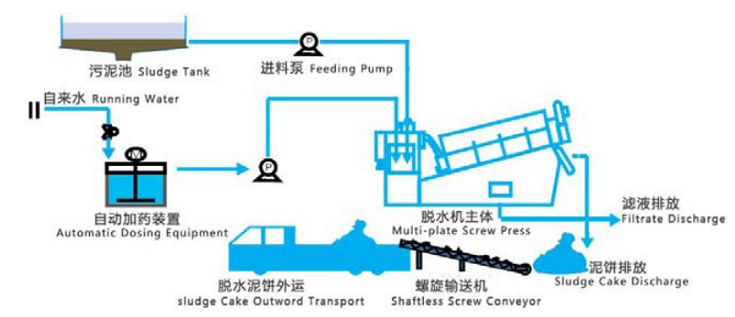

- The Dewatering Screw Press is suitable for the dewatering of high and low concentration sludge. When dewatering low-concentration (2000mg/L) sludge, there is no need to build thickening tanks and storage tanks, which reduces construction costs and reduces the release of phosphorus and the generation of anaerobic odors.

- No clogging, saving flushing water costs, and reducing the burden of internal circulation caused by the backflow of cleaning water.

- The electric control cabinet, the flocculation mixing tank and the dehydration main body are integrated, which reduces the floor space and is simple and convenient to install.

- The dehydrator is basically in closed operation, and the processing is stable and timely, so that the on-site odor is reduced to the lowest level.

- Fully automatic 24-hour operation and reduce the labor intensity of operators.

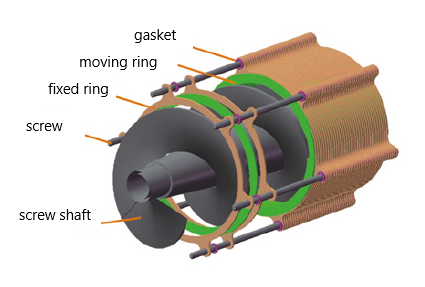

- The speed of the screw shaft is low, 2-3 r/min, low power consumption. There is basically no vibration and noise on site.

- Almost all the machine body is made of stainless steel, which can extend the service life to the greatest extent. Only the screw shaft and the moving ring are the replacement parts, and the service cycle is long.

- The daily maintenance time is short and the maintenance operation is simple.

Working Process

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160