Common Solid-liquid Separation Equipment

Generally, according to the different particle sizes, it can be divided into grids and hydraulic sieves. As the earliest solid-liquid separation equipment used, the grid gap is divided into three types: coarse, medium and fine from 1.5mm to 100mm. It is mainly used in the pre-treatment of urban sewage treatment plants to retain large suspended solids. The hydraulic screen's precision is higher, and the grid gap is between 0.1mm and 2mm. It is mainly used in the fine slag removal treatment of industrial wastewater.

Wire traction mechanical grille

Application: It is suitable for grid slag cleaning of multi-channel or wide-channel water intake, as well as water intake, rainwater pumping station or confluence pumping station, intercepting floating coarse debris or heavier sediments (sand, small stones, etc.), Generally used as medium and coarse grids (10-100mm).

Advantage:

- Wide range of adaptation, width up to 4m, maximum depth up to 30m.

- Large amount of slag (up to more than 300kg), complete slag discharge and high efficiency.

- Fewer wearing parts, no running parts underwater, easy maintenance and repair; complete operation monitoring and protection measures, extremely safe and reliable operation.

Disadvantages: The wire rope is easy to corrode and wear, and if there are fixed parts underwater, the water needs to be stopped during maintenance and inspection.

Rotary mechanical grille

Application:

1. Small suspended solids are removed between the pump station of water supply and drainage project and the fine grille of the water inlet.

2. Solid-liquid separation of industrial wastewater such as textile, printing and dyeing, slaughtering, tanning, and paper-making.

Advantage:

- High degree of automation, high separation efficiency, low power consumption, no noise, and good corrosion resistance.

- An overload safety protection device is set up. When the equipment fails, it will automatically stop to avoid overloading the equipment.

- The operating interval of the equipment can be adjusted arbitrarily according to the user's needs to realize periodic operation.

Disadvantages: maintenance is relatively troublesome, and sometimes the whole equipment must be lifted out for maintenance.

Drum type grille

Application:

1. Pre-treatment of sewage treatment equipment and subsequent decontamination, slag removal and pressing and dehydration;

2. Removal of debris in factories, hospitals, residential quarters, water intake and drainage outlets;

3. Material separation of industrial wastewater such as production, papermaking, chemical fiber, textile, printing and dyeing.

Advantage:

- Smooth operation at low speed, low energy consumption, low operating noise, large filtering area and small hydraulic loss.

- The grid and the water flow form an angle of about 35°. Due to the baffle, even many dirt with a thickness smaller than the grid gap can be separated.

- It integrates the functions of salvage, conveying and pressing, compact structure, sufficient corrosion resistance and strength, and can be used for a long time in harsh environments, while reducing the subsequent treatment costs of garbage.

Disadvantage: Dirt is easily entangled on the rake.

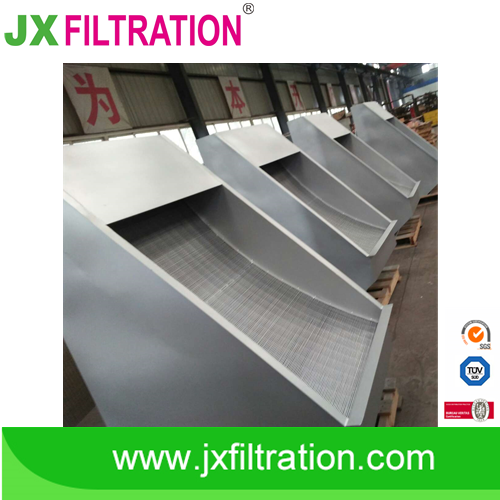

Sieve bend screen

Application:

1. It is used in the treatment of small industrial wastewater such as paper-making, slaughtering, leather, sugar making, wine-making, food processing, textile, printing and dyeing, petrochemical, etc. to remove solid substances such as suspended matter, floating matter and sediment.

2. It is used for the screening or recovery of useful substances such as recycled fiber and slag in paper-making, alcohol, starch, food processing and other industries.

Advantage:

- Use the gravity of the water flow itself to work without energy consumption; the filtering effect is good, which can greatly reduce the concentration of pollutants in the wastewater and reduce the cost of subsequent treatment of the wastewater.

- The whole machine is made of stainless steel, with high mechanical strength, no deformation and long service life.

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160