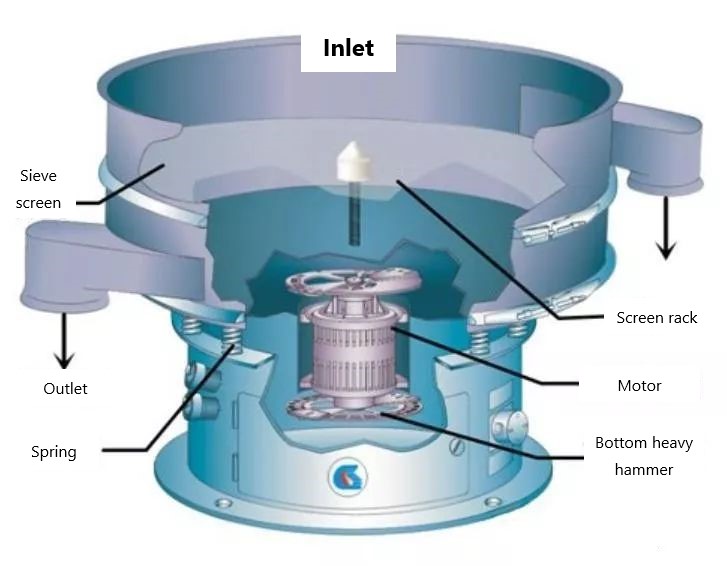

Round Vibrating Screen for Paper Industry

Working principle

The vibrating screen works by the compound-rotation vibration generated by the vibrator excitation. The upper rotating weight of the vibrator causes the screen surface to generate plane whirling vibration, while the lower rotating weight causes the screen surface to generate conical surface rotation vibration. Its vibration trajectory is a complex space curve. The curve is projected as a circle on the horizontal plane and as an ellipse on the vertical plane. Adjusting the exciting force of the upper and lower rotating weights can change the amplitude. And adjusting the spatial phase angle of the upper and lower weights can change the curve shape of the screen surface movement trajectory and change the movement trajectory of the material on the screen surface.

Features

- The design is exquisite and durable, any powder and mucus can be sieved.

- Easy to change the screen, simple to operate and easy to clean.

- Impurities and coarse materials are automatically discharged, and continuous operation is possible.

- Unique mesh frame design, the screen mesh can be used for a long time, and the mesh is changed quickly, only 3-5 minutes.

- Small size, save space, easy to move.

- Due to the strong vibration of the screen box, the blockage of the screen holes by the material is reduced, so that the screen has high screening efficiency and productivity.

- Screening consumes less electricity per ton of material.

- High filtration precision ensures the uniformity and fluidity of coatings and rubber materials, and greatly reduces paper defects such as clogging of sizing sticks and coating scraper streaks.

- It can effectively narrow the particle size distribution range when used in GCC grinding system.

Application

- Filtration and impurity removal of backflow sizing machine for paper making machine

- Filtration and impurity removal of backflow coating of paper coating machine

- Calcium carbonate grinding system dispersing material filtration

- Calcium carbonate grinding system to filter the material after grinding

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160