What are the advantages and characteristics of a Duplex Bag Filter Housing?

What are the advantages and characteristics of a Duplex Bag Filter Housing?

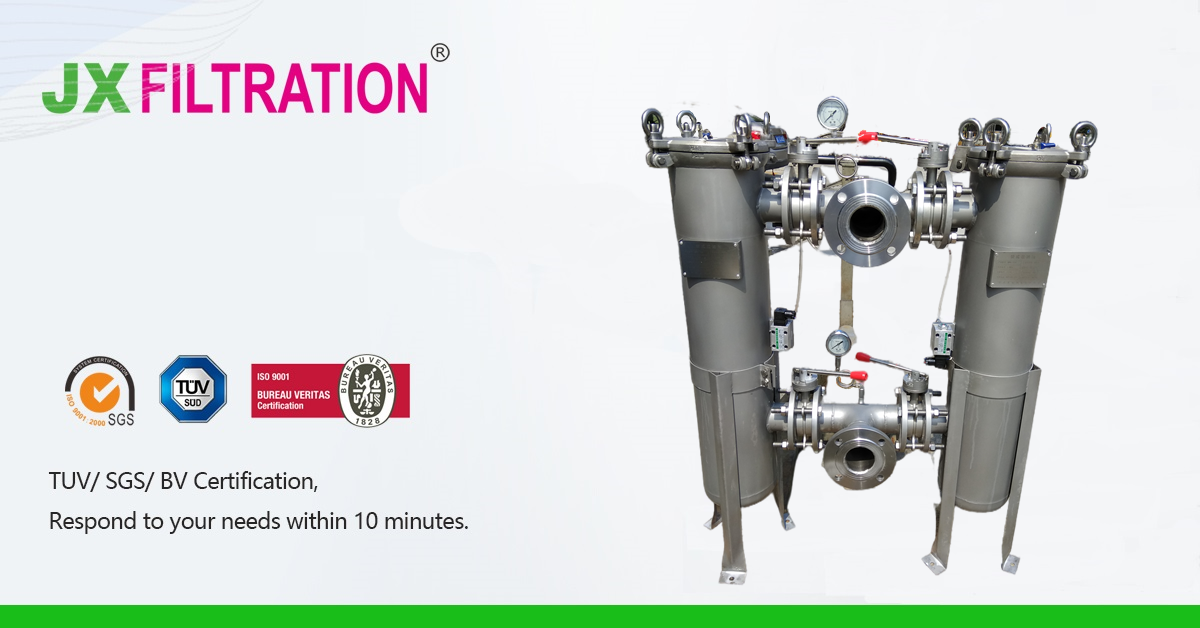

A Duplex Bag Filter Housing, as the name suggests, consists of two parallel filter chambers (or housings) that share a common inlet and outlet piping manifold, connected by a special changeover valve (or diverting valve). This design makes it invaluable for continuously operating industrial processes.

Core Advantages

The most critical and important advantages of a duplex bag filter housing can be summarized as follows:

- Continuous Operation, No Downtime Required

- This is its primary advantage. With a traditional single-chamber filter, the entire system must be shut down to replace a clogged filter bag when the differential pressure increases. This is detrimental to continuous production processes in industries like chemicals, food, and pharmaceuticals, causing production interruptions and reduced efficiency.

- The duplex design allows you to perform maintenance without interrupting the main flow. When one chamber requires maintenance, simply operate the changeover valve to divert the fluid entirely to the other chamber. The first chamber can then be isolated, and the filter bag can be replaced safely. This ensures 24/7 uninterrupted production.

- Safe and Convenient Operation

- The changeover valve design makes switching the flow path very simple, often just requiring the manual rotation of a handle.

- The chamber needing maintenance can be completely isolated and depressurized, ensuring operator safety when opening the cover and changing bags, preventing exposure to pressurized fluid.

- Protects Downstream Equipment, Improves System Reliability

- During the brief shutdown of a single-housing filter for bag changes, unfiltered contaminants or air could enter downstream sensitive equipment (e.g., nozzles, heat exchangers, pumps).

- The duplex filter ensures continuity of the filtration process, providing a constant supply of clean fluid to downstream equipment and avoiding potential equipment risks or product quality issues caused by filtration interruptions.

- Reduces Labor Intensity, Optimizes Maintenance Scheduling

- Maintenance personnel do not need to wait for a full system shutdown and can change filter bags at their convenience.

- For applications requiring frequent bag changes, the duplex filter significantly reduces the number of emergency shutdowns, making maintenance more planned and predictable.

Key Characteristics

Beyond the core advantages above, duplex bag filter housings also have the following structural and operational features:

- Twin-Chamber Parallel Design: Two independent filter chambers connected via a common inlet and outlet manifold.

- Three-Way Changeover Valve: This is the key component enabling its functionality. It typically has three positions:

- Position A: Fluid flows only through Chamber A.

- Position B: Fluid flows only through Chamber B.

- Center Position: Fluid flows through both chambers simultaneously (commonly used for normal operation to balance flow and extend bag life).

- Independent Vent and Drain Ports: Each chamber usually has its own vent and drain valves, facilitating depressurization and drainage before maintenance, as well as venting during initial startup.

- Differential Pressure Gauge (Optional): Many duplex housings are equipped with a differential pressure gauge to visually indicate the degree of filter bag clogging, alerting operators when it's time to switch chambers for maintenance.

- Flexible Construction Materials: Can be manufactured from various materials based on the fluid being processed (e.g., corrosion, sanitary requirements), such as carbon steel, 304 stainless steel, 316 stainless steel, with various finishes (e.g., sandblasted, coated, polished).

- High Capacity Filtration: Each chamber can hold multiple or large-sized filter bags, offering high flow rates and high dirt holding capacity.

Application Scenarios

Duplex bag filter housings are particularly suited for the following applications:

- Continuous production processes: Such as production lines in petrochemical, fine chemical, resin, paint, and ink industries.

- Critical systems where downtime is not allowed: Such as equipment coolant filtration, paint circulation filtration in spray lines, or pulverized coal injection systems for blast furnaces.

- Industries with high sanitary requirements: Such as food and beverage (beer, juice, milk) and bio-pharmaceuticals, where product contamination must be prevented and production must not be interrupted.

- Filtration of high-value fluids: Prevents product loss during bag changes since the system remains operational and flow is diverted to the other side.

In summary, the greatest advantage of a Duplex Bag Filter Housing is its ability to enable "online changeover and continuous filtration." Although its initial investment cost is higher than a single-housing filter, the value it brings to modern industrial processes that prioritize production efficiency, product quality, and system reliability far outweighs the cost difference.

Contact us now for a tailored solution.

Julie

Email: sales@filtrationchina.com

Mobile / WA / WeChat: +86 159 2865 0174