The Hidden Potential of Bag Filters: Versatile Applications for Infinite Industrial Filtration Possibilities

Bag filters are widely valued in the industrial filtration sector for their flexibility and efficiency. However, many may not realize that with simple configuration adjustments or media replacements, bag filters can perform far beyond traditional filtration modes. Whether it's adsorbing oil, improving precision, or reducing costs—they handle it all with ease. Below, we explore several highly effective applications of bag filters to help you maximize your equipment’s potential.

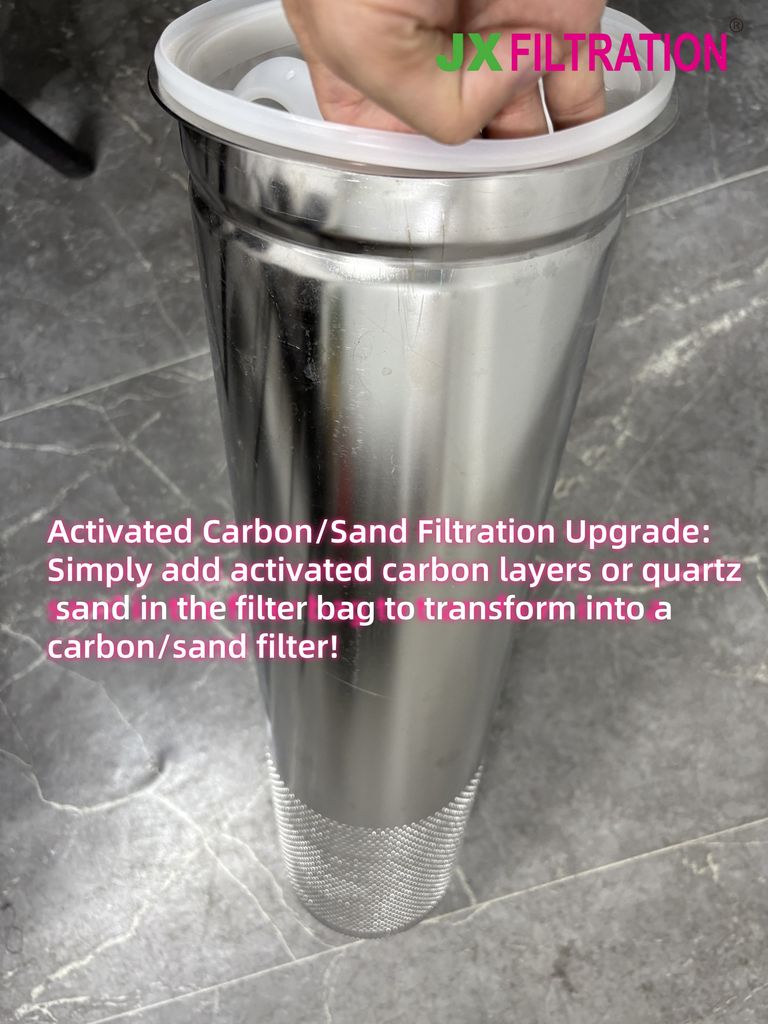

1.Transform into Activated Carbon and Sand Filters for Integrated Adsorption and Purification

By simply replacing the filter housing and adding an activated carbon layer or quartz sand, an ordinary bag filter can be upgraded into an activated carbon or sand filter system. When paired with specialized activated carbon filter bags, it effectively removes organic matter, residual chlorine, and odors from water. This makes it ideal for applications such as chemical processing, electronics ultrapure water pretreatment, and industrial wastewater treatment.

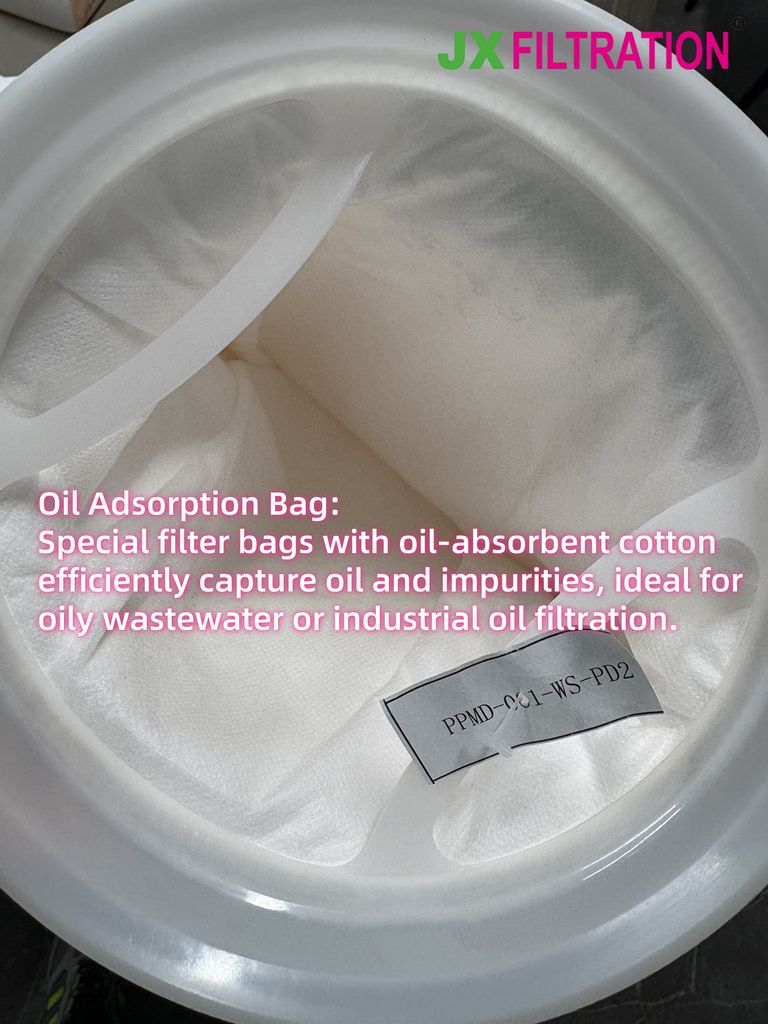

2.Special Filter Bags for Powerful Oil Absorption, Effortlessly Handling Oily Fluids

For oil-containing coolants or industrial wastewater, special filter bags equipped with oil-absorbent cotton can be used. These bags quickly absorb and retain oils, reducing system contamination. They are particularly suitable for machinery processing, metal cleaning, and other scenarios prone to oil-fluid mixtures.

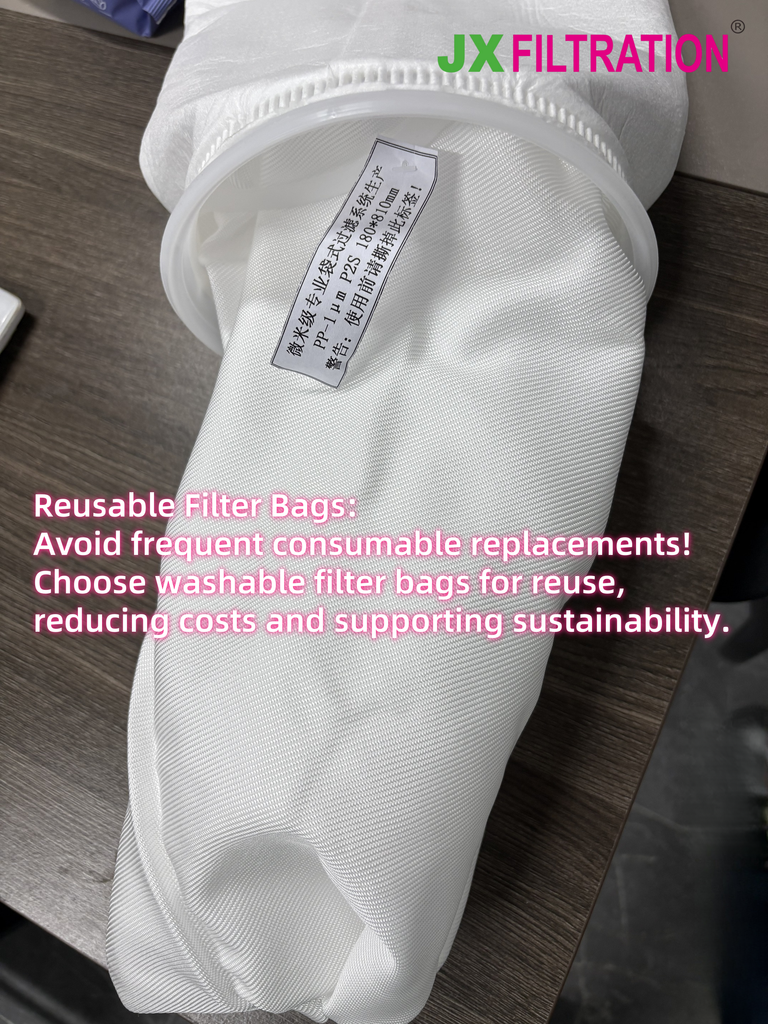

3.Reusable Washable Filter Bags for Lower Long-Term Operating Costs

Tired of frequent media replacements? Washable filter bags are an ideal solution. Made from durable materials like polyester or polypropylene, they can be rinsed and reused multiple times, significantly cutting down on bag replacement costs—especially useful for pre-filtration or coarse filtration stages.

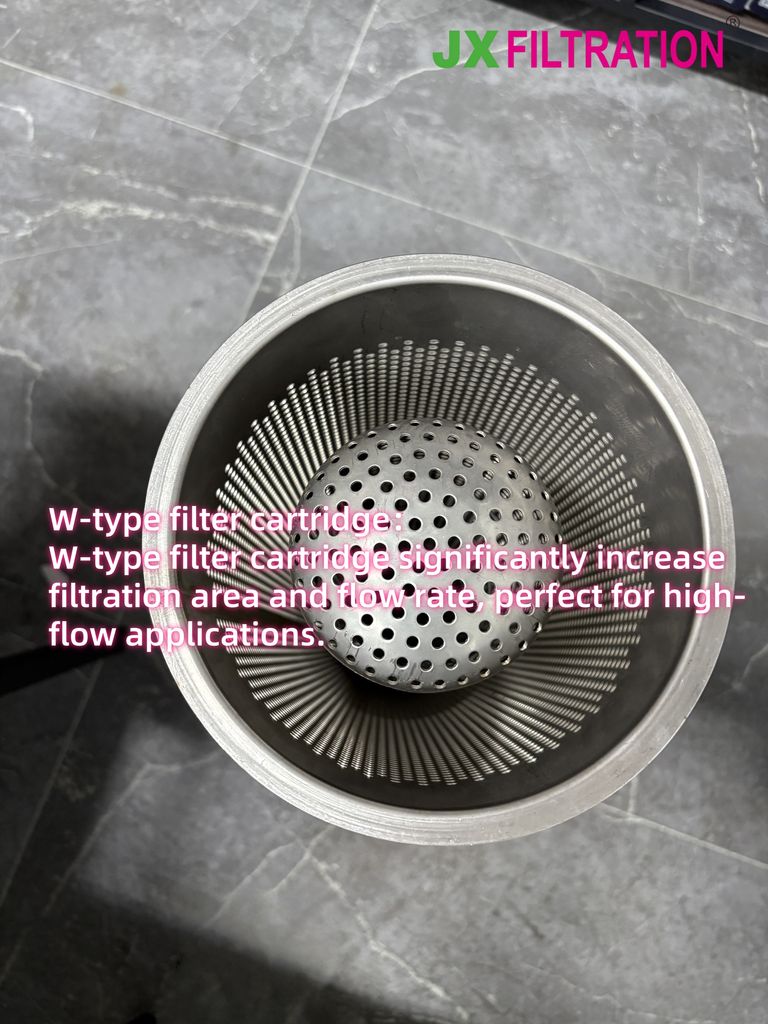

4.W-Type Filter Housings and Bags for Increased Filtration Area and Flow Rate

For high-flow applications, W-type filter housings and compatible W-type filter bags can be selected. Their unique pleated structure greatly increases the effective filtration area, supporting higher flow rates within the same footprint. This makes them well-suited for large-scale continuous production in industries like water treatment and coatings.

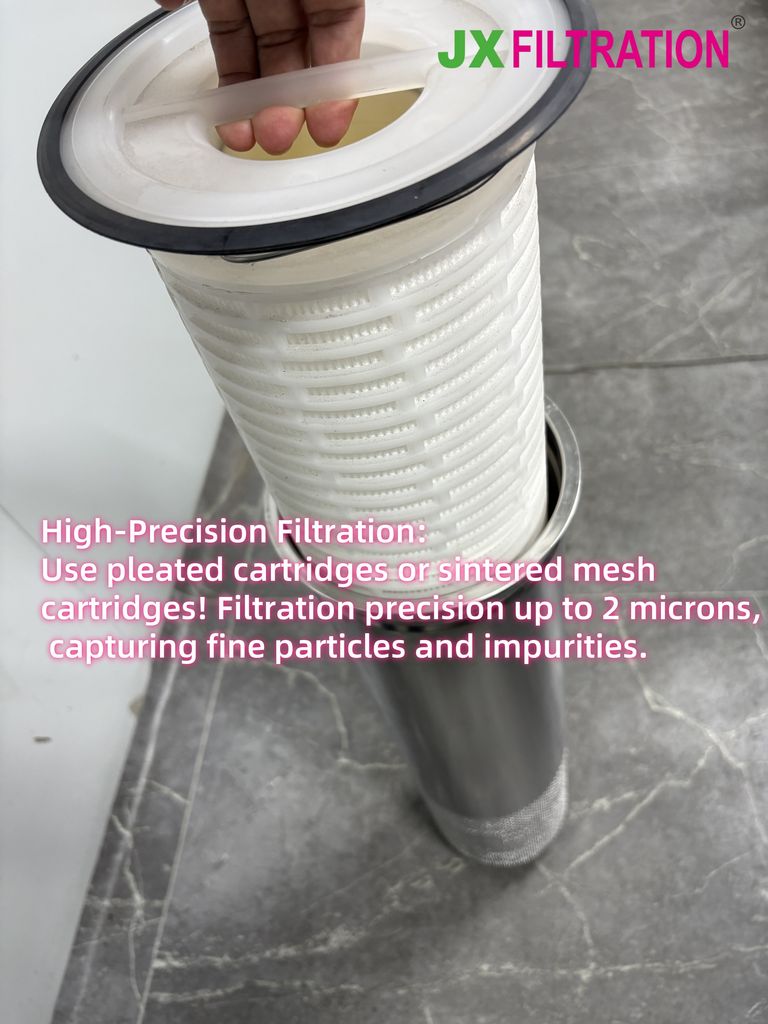

5.High-Precision Pleated Cartridges or Sintered Mesh Cartridges for Enhanced Filtration

When higher filtration precision (e.g., 2 microns) is required, consider switching from standard filter bags to pleated cartridges or sintered mesh cartridges. These media offer dense structures and high dirt-holding capacity, making them suitable for industries with strict hygiene standards such as food and pharmaceuticals.

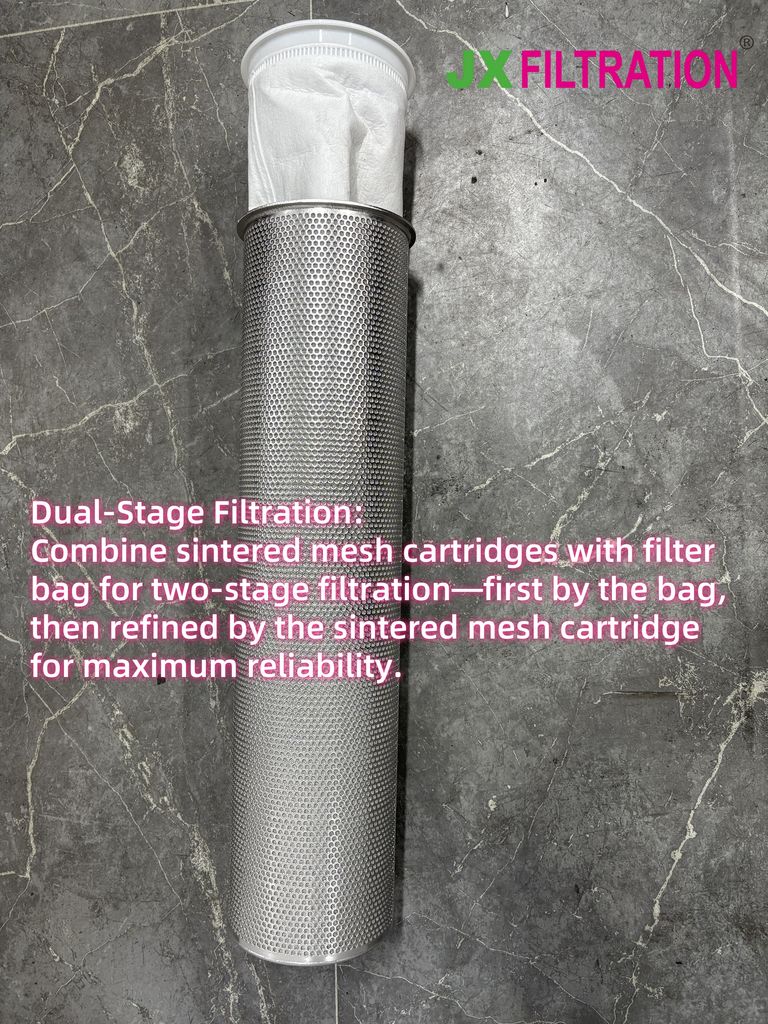

6.Sintered Mesh Cartridge + Filter Housing Combination for Two-Stage Filtration

By adding a sintered mesh cartridge basket alongside the filter bag, a two-stage filtration system is created: the bag handles initial filtration, while the sintered mesh captures finer particles. This combination is especially effective in applications demanding extremely high fluid cleanliness, such as precision electronics cleaning or high-end pharmaceutical manufacturing.

Whether it’s adsorption purification, high-flow filtration, or high-precision needs, bag filters can meet diverse challenges through flexible configurations. Multi-functional by design, they represent not only a technical upgrade but also an intelligent balance between cost and efficiency. Choose the right filtration solution to make your processes more efficient and economical!

One Filter, Multiple Uses—Filtration Made Worry-Free.

Contact us now.

Julie

Email: sales@filtrationchina.com

Mobile / WA / WeChat: +86 159 2865 0174