Why Choose Mechanical Bar Screen?

To address the problems of overgrowth of aquatic plants in natural water bodies, which can lead to blockages and inefficiencies in irrigation systems, Mechanical bar screen, as efficient and reliable physical filtration devices, play a key role in pre-treatment at the water source. The following briefly describes the working principles of mechanical screens and their technical advantages in removing river weeds.

I. Mechanical Screens: Principles of Automated Solid-Liquid Separation Technology

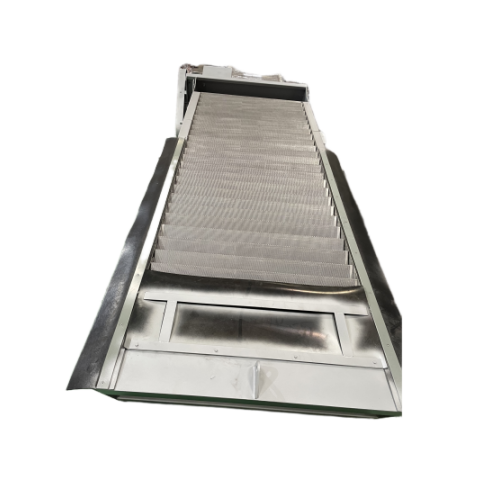

A mechanical screen is an automated cleaning device that integrates mechanical drive and electrical control. It is primarily used to intercept and remove suspended and floating solid debris from the water flow. When used at a river intake, its workflow is as follows:

1. Precision Interception Process.

The device is installed at the front end of the water intake structure. As raw water flows through the screen body, the bars with precisely defined gaps effectively intercept solid impurities such as weeds, branches, and suspended matter, achieving initial separation.

2. Automated Cleaning Mechanism.

Based on a preset time period or a control signal triggered by a liquid level differential sensor, a drive mechanism activates the cleaning rakes, automatically scooping up debris trapped on the screen surface.

3. Centralized Debris Disposal.

The collected debris is transported to the discharge port via a lifting mechanism, where it falls into a collection container or a matching conveying device, enabling centralized collection and subsequent harmless treatment of aquatic weeds.

II. The Core Value of Mechanical Screens in Irrigation Aquatic Weed Filtration.

Using mechanical screens in irrigation water pretreatment can systematically address the numerous issues caused by aquatic weeds.

1. Ensures safe and stable operation of the pump.

Effectively prevents aquatic weeds from entangled in the pump impeller, avoiding the risks of idling, overload, and motor burnout.

2. Ensures smooth and efficient irrigation pipework.

Removing fibrous impurities such as aquatic weeds fundamentally prevents clogging of drip irrigation tapes, sprinklers, and filters at all levels, ensuring uniform distribution of irrigation water and overall system efficiency.

3. Improves water resource utilization efficiency.

By ensuring continuous and stable system operation, it reduces water waste caused by clearing blockages or equipment maintenance, thereby improving irrigation water efficiency.

4. Promotes the ecological and environmental cycle of agriculture. Collected

aquatic weeds can be composted as organic waste and converted into soil conditioner or organic fertilizer for re-use in farmland.

As a key component of irrigation water pretreatment, mechanical screens, with their efficient solid-liquid separation capabilities, provide a technically reliable and economically viable solution to the problem of aquatic weed blockage. They create a solid physical barrier at the water source, not only directly ensuring the smooth operation of the irrigation system but also, in the long term, enhancing the modernization and risk resilience of agricultural water resource management.

Any requirements, contact us now!

Nina

Email: nina@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 172 6957 1060