Self-Cleaning Rotary Drum Screen - JX Filtration

Application: it can remove fine particles above 0.25mm in diameter from the water. Suitable for papermaking, leather making, slaughtering, brewing, the pretreatment of wastewater treatment such as wine, printing and dyeing, textile, washing plastic, chemical industry, etc.

The pre-treatment has a great influence on the whole sewage treatment process. The high treatment efficiency of pre-treatment has a certain influence on the processing capacity of the subsequent sewage treatment system, the frequency of maintenance and so on. As an important pretreatment equipment in sewage treatment, microfilters are mainly used to separate large suspended solids in sewage.

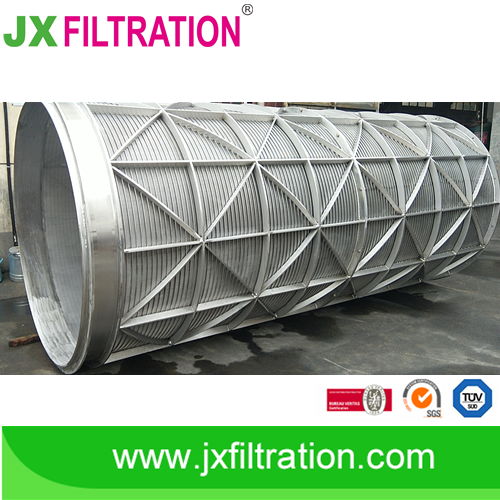

Overview of Self-Cleaning Rotary Drum Screen

The Self-Cleaning Rotary Drum Screen is a new type of drum screen filter and separation equipment. The stainless steel mesh with 15-20 micron pores is usually used for filtration process. It is suitable for separating impurities (micro-suspended matter, fiber, distiller's grains, pulp, etc.) in liquid to achieve the purpose of solid and liquid phase separation.

The Self-Cleaning Rotary Drum Screen is a mechanical self-cleaning filter with a unique filtration design. It has high fluidity under low water resistance and retains suspended solids. This equipment works under pressureless conditions makes it have a longer service life and lower maintenance costs. It is widely used in various occasions where solid-liquid separation is required.

Main structure

The Self-Cleaning Rotary Drum Screen is composed of transmission device, wedge wire drum screen, overflow weir, flushing water device and other main components. The drum screen adopts 2mm stainless steel wedge wire mesh as the filter screen, which is firm and reliable, non-clogging, corrosion-resistant, and easy to clean.

Features

1. Simple structure, stable operation, convenient maintenance and long service life.

2. Large filtration capacity, high precision, and the recovery rate of small suspended solids in wastewater is greater than 80%.

3. Small footprint, low cost, low-speed operation, automatic protection, and easy installation.

4. Fully automatic and continuous work, no need to be supervised by special personnel, and the concentration of filtered substances is more than 10%

5. It can be used instead of coarse filtration equipment such as mechanical grids.

Working principle

The treated water enters the overflow weir distributor from the water pipe. After a short steady flow, it overflows evenly from the water outlet. The solids are distributed on the filter cartridge filter screen and slowly form a filter cake to prevent the filter screen, causing the liquid level to rise.

When the liquid level reaches the set height, the circuit is triggered, the filter cartridge starts to rotate and the high-pressure water pump starts to clean the filter screen. When the liquid level drops, the trigger circuit closes the drum screen and the high-pressure water pump. The filter drum screen of the machine is equipped with a water pump and a flushing water pipe, which are sprayed in a fan shape to flush and clear the filter screen to ensure that the filter screen always maintains a good filtering capacity.

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160