How Does Sieve Bend Operate?

Sieve Bend is used in various types and sizes of sewage treatment projects. It can remove floating matter and suspended matter etc., reducing post-processing workload, strengthening biological treatment processes, and saving operating costs. It is also used in the concentration of various liquid-solid mixtures.

Working principle

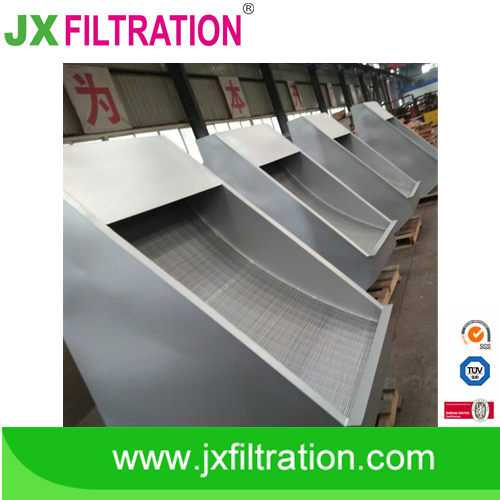

The main body of the Sieve Bend is a stainless steel arc-shaped or flat filtering screen surface made of wedge-shaped steel rods. The waste water to be treated is evenly distributed on the inclined screen surface through the overflow weir. Due to the small and smooth surface of the screen, the gap on the back is large.

The drainage is smooth and not easy to block; the solid matter is intercepted, and the filtered water flows out from the gap of the sieve plate. At the same time, the solid matter is pushed to the lower end of the sieve plate to be discharged under the action of hydraulic force, so as to achieve the purpose of solid-liquid separation.

Typical application industry

1. Paper-making wastewater—recycle fiber and remove solids.

2. Tannery wastewater—removal of solids such as fur and grease.

3. Slaughter Wastewater—Remove solids such as pouches, fur, grease, feces, etc.

4. Urban domestic sewage—remove solids such as fur and debris.

5. Alcohol, starch factory wastewater—removal of solids such as plant fiber shells, groceries, etc.

6. Wastewater from pharmaceutical factories and sugar factories—removal of solids such as various waste residues and plant shells.

7. Wastewater from beer and malt plants—removal of solids such as malt and soybean hulls.

8. Poultry and livestock farms—removal of poultry and livestock hair, feces and other solid materials.

9. Fish and meat processing plants—removal of solids such as viscera, scales, minced meat, grease, etc. Others such as the pre-treatment of sewage from chemical fiber plants, textile plants, chemical plants, plastic processing plants, large-scale machinery plants, hotels, residential areas, etc.

Technical Specifications

- Material: SS304, SS304L,SS316,SS316L or any other corrosion-resistant materials

- Dimensions: can be customized according to the treatment capacity

- Slot size can achieve various specifications such as 0.25mm, 0.5mm, 0.75mm, 1.0mm, 1.5mm, 2mm, etc.

- Work with the gravity of the water flow itself without energy consumption.

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160