Pig Farm Wastewater Treatment Method and Process

The main characteristics of pig farm wastewater: high concentration of organic matter, high content of suspended solids, deep color, a large amount of bacteria, and high concentration of NH-N.

Treatment Method:

1. Physical treatment

The method can be divided into gravity separation method, centrifugal separation method and sieve filtration method.

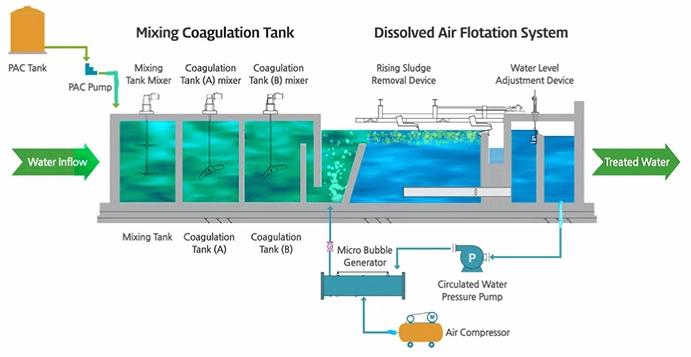

- Gravity separation method: include sedimentation, air flotation ( DAF unit), etc.

- Centrifugal separation method: centrifugal separators and hydrocyclone separators, etc.

- Sieve filtration method: grid interception and filtration. The former uses grids and screens, while the latter uses sand filter tank and rotary drum filter, etc.

2. Chemical treatment

Wastewater treatment method that separates and removes dissolved and colloidal pollutants in wastewater or converts them into harmless substances through chemical reaction and mass transfer.

- The processing units based on chemical reactions caused by the dosing of chemicals are: coagulation, neutralization, redox, etc.

- The processing units based on mass transfer include: extraction, stripping, stripping, adsorption, ion exchange, and electrodialysis and reverse osmosis, etc.

3. Biological treatment

Through the metabolism of microorganisms, organic pollutants in solution, colloid and fine suspension in wastewater are converted into stable and harmless substances.

Treatment Process:

- Pretreatment

For large particulate matter or easily settling matter in wastewater, the animal raising industry uses filtration, centrifugation, sedimentation and other solid-liquid separation technologies for pretreatment. Among them, sieve filtration and sedimentation are commonly used and common processes are grid and solid-liquid separation (vibrating screen and rotary drum separator).

- Biochemical treatment (secondary treatment)

Biochemical treatment can be divided into anaerobic biochemical treatment, aerobic biochemical treatment and natural treatment according to its working principle.

In the anaerobic treatment process, the organic matter in the wastewater is finally converted into methane, carbon dioxide, water, hydrogen sulfide and ammonia by a large number of microorganisms. Common method: CSTR, AF, UASB, AFB, USR.

In aerobic treatment, the biodegradable organic matter can finally be completely oxidized to simple inorganic matter.

Natural treatment: purify sewage by using the physical, chemical and biological integrated effects of natural water, soil and organisms.

- Advanced processing (three-level processing)

Coagulation sedimentation method: add coagulant to destabilize the colloids and fine suspended solids, and aggregate them into alum flowers of hundreds of microns or even a few millimeters, which can then be treated by gravity sedimentation or other solid-liquid separation methods.

Membrane separation technology: uses a special membrane to selectively separate the components in the liquid include diffusion dialysis, electrodialysis, reverse osmosis, ultrafiltration, microfiltration, etc.

MBR: The membrane separation equipment is used to trap the activated sludge and macromolecular organic substances in the biochemical reaction tank. The hydraulic retention time (HRT) and sludge retention time (SRT) can be controlled separately, and the refractory substances are continuously reacted and degraded in the reactor.

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160