How many Screen Connection Types?

There are three main connection types: flange connection, thread connection and welding connection.

The stainless steel screen tube also called wire mesh filter screen has a variety of connection methods for different purposes such as flange connection, thread connection and welding connection.

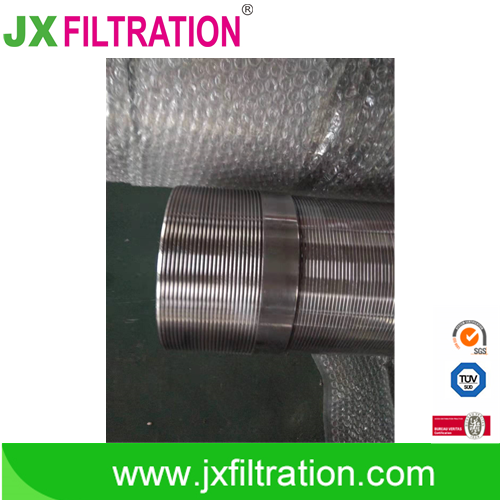

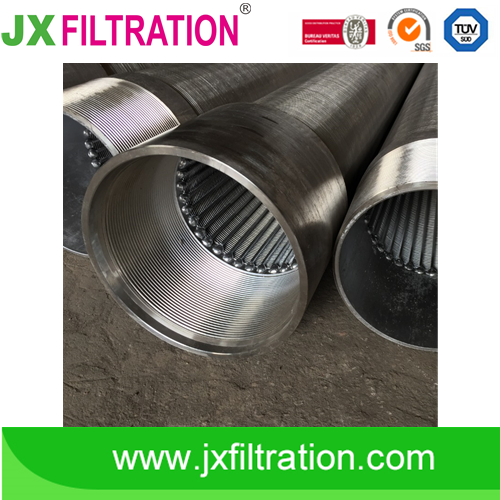

Thread connection

Threaded connection is one of the most widely used connection methods. The threaded screen is relatively stable, and there is no need to worry about slight leakage, and it is suitable for medium and low pressure working conditions. It is especially suitable for occasions where the wedge wire screen will not be disassembled for a long time. However, it is not recommended to use under vibration and shaking conditions.

Welded connection

For welded connection, there is no need to consider disassemble the screen. It is suitable for occasions where temperature and pressure change periodically. High temperature and high pressure may cause flanges and threads to loosen or high-frequency vibration. Therefore, welding is the best choice under high temperature and high pressure working conditions.

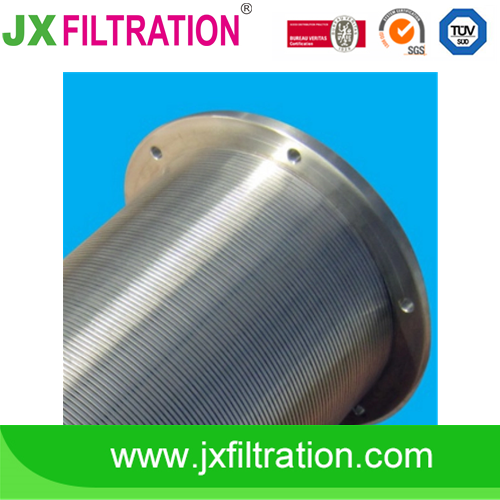

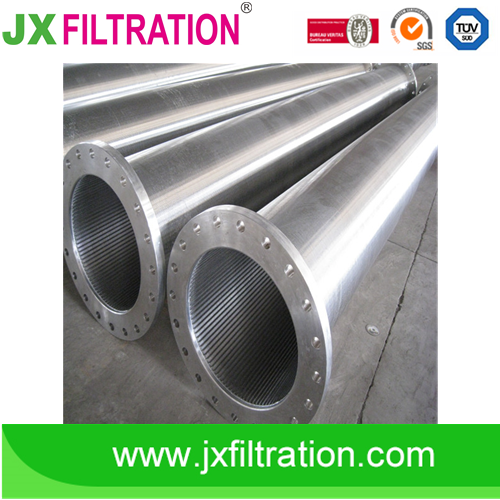

Flange connection

Flange connection is a detachable tight connection method. It uses two flanges to connect pipes, valves, equipment and other components into a tight piping system. It is easy to disassemble and assemble, and can form a reliable connection to withstand low pressure or high pressure according to different application requirements. It is relatively stable in a vibrating conditions.

The wedge wire screen, wedge wire panel, water well screen, wedge wire nozzle, sieve bend screen screen wire for sale.

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160