How Does a Rotary Vacuum Filter Work?

Rotary Vacuum Filter mainly applied in sugar, starch, gypsum and any other powdered particles filtration and dryness.

Rotary vacuum filter (Vacuum drum filter) is a external filter surface, continuous filtration, washing, drying, unloading, the filter cloth can be blown and washed, and the bottom feed (also top feed) filter equipment that operates continuously under vacuum conditions.

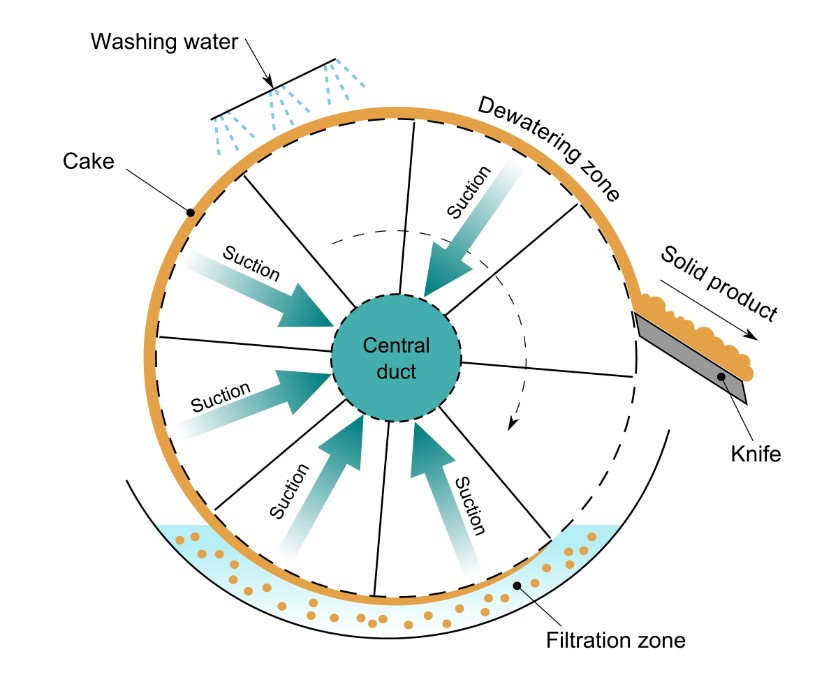

The surface of the filter is divided into many identical chambers, and the horizontal rotating drum and filter cloth that continuously circulate move synchronously.

The outer surface of the Rotary Vacuum Filter is divided into multiple functional areas:

- Suction and Filtration area

- Washing and cleaning area

- Dewatering area

- Unloading and filter cloth regeneration area

Then the filter cloth is drawn out, and the filter cloth is discharged by the scraper. The filter cloth will be cleaned and regenerated, and then it returns to the four area recycle.

For the whole machine, filtering, washing, drying, unloading, and regeneration are in different parts.

According to the different discharging methods, it is divided into: scraper vacuum drum filter, folding belt vacuum drum filter, roller discharge vacuum drum filter, rope discharge vacuum drum filter, and pre-coated vacuum drum filter derived from the scraper vacuum drum filter scraper.

Any requirements, contact us now!

GraceMobile/Whatsapp/WeChat:+86 17269571160