Cylindrical Wedge Wire Screens

Application: Oil and gas industry, chemical industry, paper making, water treatment.

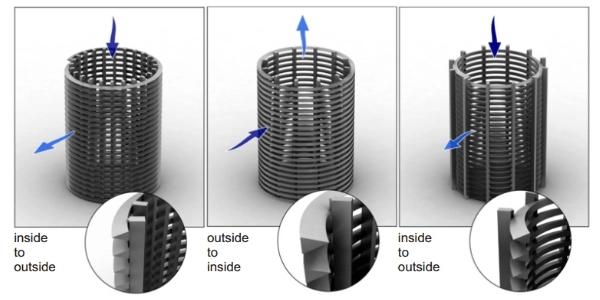

The Cylindrical Wedge Wire Screens adopts a full-wound welding production process, and is welded on a set of support wires arranged in a circular pattern with a special trapezoidal wire winding.

The full-process welding ensures the strict continuous integrity of the product, so that it forms an ideal slot size and has the performance to withstand the maximum amount of high pressure.

Features:

- The application of trapezoidal wire creates a V-shaped opening between the screen gaps.

- The continuous winding of trapezoidal wire forms a continuous high-density uniform gap on the support wire arranged in a circle.

- The winding wire and all supporting wires are connected by electric welding, which is strong and durable and has a long working life.

- The longitudinal arrangement of the support wires and the continuous gap form of the screen designed make the Cylindrical Wedge Wire Screens high in compression performance.

- The advantages of Cylindrical Wedge Wire Screens improve the efficiency and service life of the well.

Technical data:

- Gap (mm): 0.10, 0.15, 0.2, 0.25, 0.30-3 (can be customized)

- The opening area is up to 60%

- Material: low carbon steel, low carbon steel galvanized, stainless steel (304,316 etc.) (can be customized)

- The longest length is 6 meters (can be customized)

- The outer diameter is from 25mm to 800mm (can be customized)

- Connection form: groove connection or threaded connection

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160