Sieve Bend Screen

Sieve Bend Screen, also called DSM screen, Arc screen, Corn Starch Screen and parabolic screens, can be custom designed with various dimension to suit the machine that separate solids from liquids. It is widely used in food processing, pulp and paper, waste water cleanup, surface water intakes, corn wet milling, coal preparation, and gold recovery.

Sieve Bend Screen consist of V-shape profile wire and the longitudinal support rods. It is manufactured by wrapping and welding stainless steel V-shaped profile wire on the support rods. Then the panel screens are cut and curved with different angles.

Advantages

- V-shape section can avoid blockage

- Slightly tilted profile wires and higher position of the the leading edge to ensure higher dewatering capacity

- Stainless steel construction material to ensure higher chemical and thermal resistant

- High mechancial strength and intensity

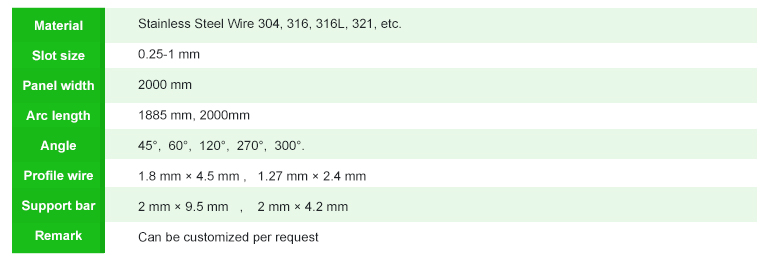

Specification

Sieve Bend Screen-Application

- Starch screens

- Sugar mill

- Mineral processing

- Waste water cleaning up

- Condensate water filtration

- Column bottoms purification

- 45° DSM Screen is suitable for thickening and screens

- 120° DSM screen is used for separating water suspension