Product

Sieve Bend Screens

Our Advantage

Slot opening from 0.02mm-20mm.

22 fully automatic production line, 7x24 hours uninterrupted production.

Strictly selected steel supplier to ensure the stable quality and price.

Wedge Wire Screen, DSM Screen, Sieve Bend Screen, Sieve Bend Screens.

Complete production line, from wiredrawing to wire rolling and finished product.

Sieve Bend Screens

Description

Sieve Bend Screens also known as side hill screens, parabolic screens, run down screens, gravity screens and DSM Screen, can be custom designed to separate solids from liquids in various applications including food processing, pulp and paper, waste water cleanup, surface water intakes, corn wet milling, coal preparation, and gold recovery.

.jpg)

Sieve Bend Screens are made of stainless steel Wedge Wire. They are consisting of a concave curved profile wire screen, which are inserted into a stainless steel frame. The Sieve Bend are manufactured by wrapping and welding stainless steel V-shaped profile wire and support rods. Then the panel screens are cutting and curved into arc screen.

.jpg)

Sieve Bends are cross-flow screens. The profile wires are slightly tilted so that the leading edge is position higher which greatly increases the dewatering capacity.

.jpg)

A sieve bend consists of a concave curved profile wire screen mounted in a frame with the screen openings perpendicular to the flow. A curved screen has greater capacity than a flat wedge screen due to forces exerted as material flows against the curved surface.

Application

Starch screens

Sugar mill

Mineral processing

Waste water cleaning up

Condensate water filtration

Column bottoms purification

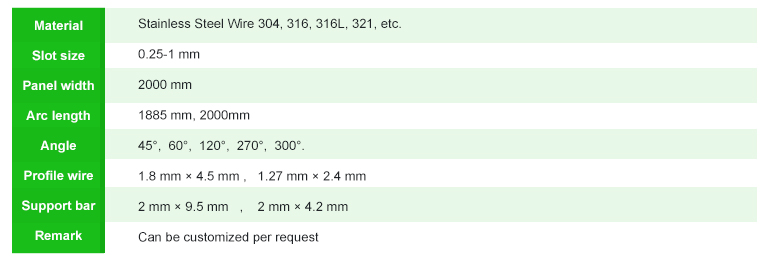

45° DSM Screen is suitable for thickening and screens

120° DSM screen is used for separating water suspension

Above is the summary info about DSM Screen, here shows the specifications about profile wire and the screen

.jpg)

Sieve Bend Screens

Related Product

Sieve Bend Screens

Related Cases

Product

Sieve Bend Screens

FAQ

Where is your factory?

We have three factories in Sichuan, Hebei, Jiangsu. Because the difference of customer locations, raw material price, factory wages and other considerations. In this way, we can provide the best quality product with lower cost.

Do you have a certification?

Yes. we have ISO/CE/BV/SGS/TUV certificate and patent certificate.

How about the delivery time?

Usually 1-15 days after prepayment is confirmed.

Do you have a design team?

Yes, we have. Providing drawing, electric drawing and others.

What is your payment?

T/T, L/C, Western Union, Paypal.

Can you provide certificate of origin?

yes, we can provide CO as well as FORM E, FOEM F and etc.

Can you accept OEM?

Yes, we could do OEM for you.

Can you send me a sample?

Yes.1-3 days for delivery.

Sieve Bend Screens

Our Service

Professional Pre-sale

Service

Filtration method and

equipment recommendation.

Free CAD or 3D

drawing provided.

Free phone call.

Complete Service

During Sales

On time delivery.

Equipment inspection

by photo or video.

Secure and standard

package provided.

After Sales Service

Installation assist by

phone call or video.

Free accessories provide

for maintenance.

Engineer sent for

solving onsite problem.