What is Volute Press for Sludge Dewatering?

Application: Municipal sewage treatment projects and water treatment systems in the food, starch, oil, pharmaceutical, chemical, paper, leather and other industries.

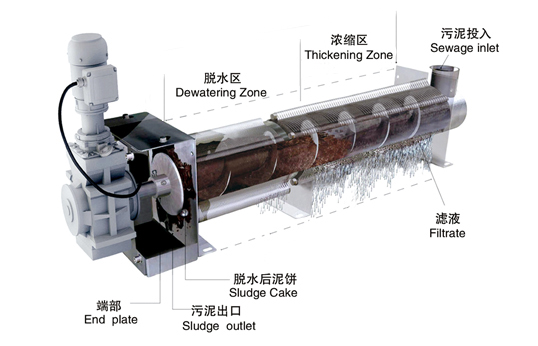

The Volute Press for Sludge Dewatering can realize high-efficiency flocculation under the condition of fully automatic operation, and continuously complete the sludge thickening and dewatering work, and finally return or discharge the collected filtrate.

Structure and working principle of Volute Press for Sludge Dewatering

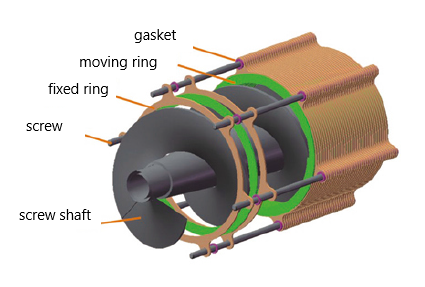

The Volute Press for Sludge Dewatering integrates a fully automatic control cabinet, a flocculation tank, a sludge thickening and dewatering body and a liquid collecting tank in one. The main body is a filter device formed by stacking a fixed ring and a moving ring with a spiral shaft penetrating through it.

The front section is the thickening zone, and the rear section is the dewatering zone. The filter gap formed between the fixed ring and the moving ring and the pitch of the screw shaft gradually decrease from the thickening zone to the dewatering zone. The screw shaft continuously drives the ring to clean the filter gap to prevent clogging. While the rotation of the screw shaft pushes the sludge from the thickening zone to the dewatering zone, and under the blocking action of the end plate, it generates a great internal pressure, the volume is continuously reduced.

Advantages of Volute Press for Sludge Dewatering:

- Strong resistance to oil sludge, easy to separate and not clogged.

- Integrated sludge thickening and dewatering functions. Low-concentration sludge can be directly dewatered.

- Diverse models: wide range of applications.

- Compact design to save installation space.

- Simple operation and maintenance.

- Water saving, power saving and low noise.

- Thoughtful and timely after-sales service

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160